Automobile part airtightness detection mechanism

An auto parts, air tightness technology, applied in the direction of detecting the appearance of the fluid at the leak point, by measuring the acceleration and deceleration rate of the fluid, using the liquid/vacuum degree for the liquid tightness measurement, etc. Uneven force, inaccurate detection and other problems, to achieve the effect of solving uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below by specific embodiment:

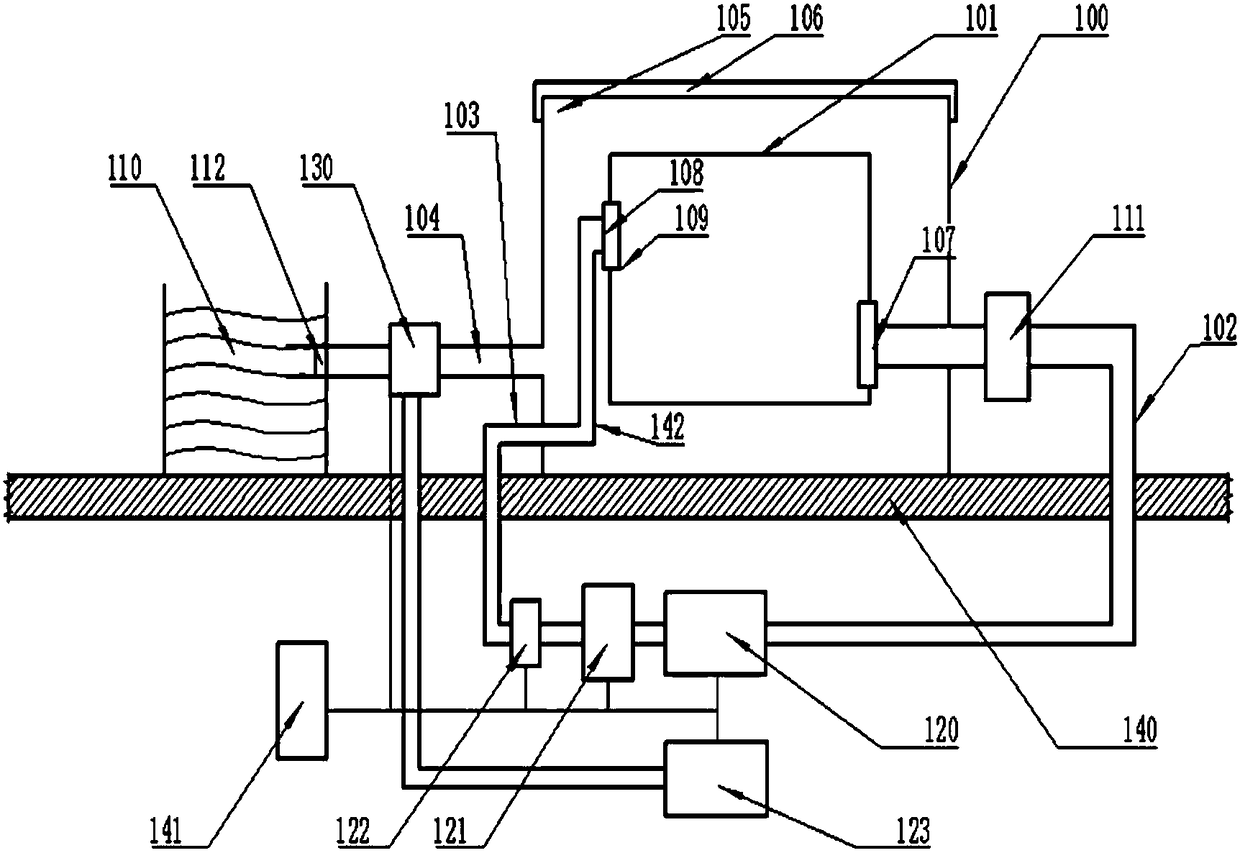

[0015] The marks included in the accompanying drawings of the description of the present invention are: box body 100, fuel tank 101, air intake pipe 102, air outlet pipe 103, vacuum air pipe 104, opening 105, cover body 106, air inlet 107, air outlet 108, expansion rubber ring 109 , water tank 110, air pressure sensor 111, one-way air valve 112, air pressurizer 120, air heater 121, solenoid valve 122, vacuum pump 123, three-way solenoid valve 130, frame 140, control circuit 141, Metal hose 142.

[0016] Such as figure 1 As shown, the mechanism that can detect the airtightness of auto parts includes a box body 100 and a pipeline. The box body 100 is provided with an opening 105, and the opening 105 of the box body 100 is provided with a cover body 106 that can completely cover the opening 105. , the box body 100 is provided with a cavity for placing the test piece, the two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com