High-voltage transmission line inspection robot

A technology of high-voltage transmission lines and inspection robots, which is applied in the direction of overhead lines/cable equipment, etc., and can solve problems such as high risk, inability to inspect lines over long distances, and high clamping force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the contents of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

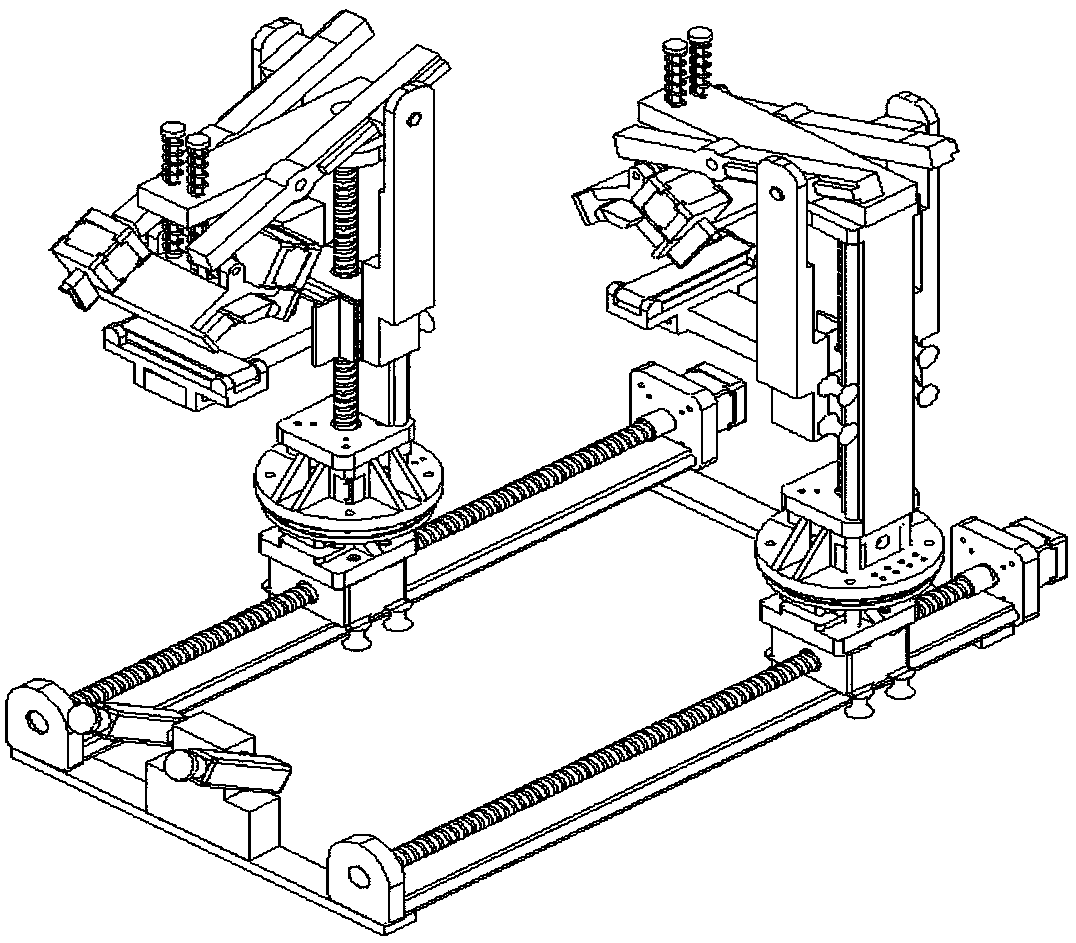

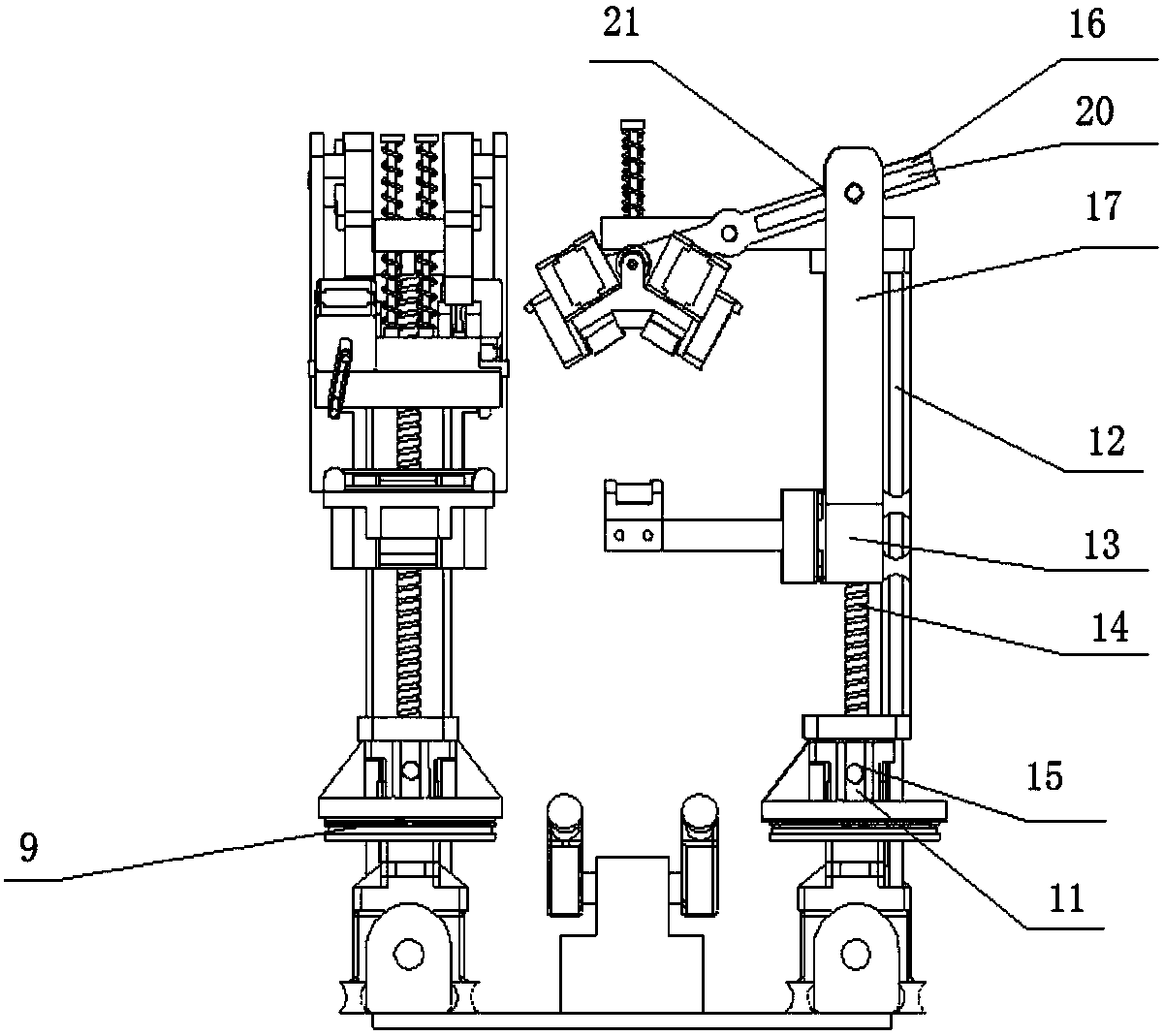

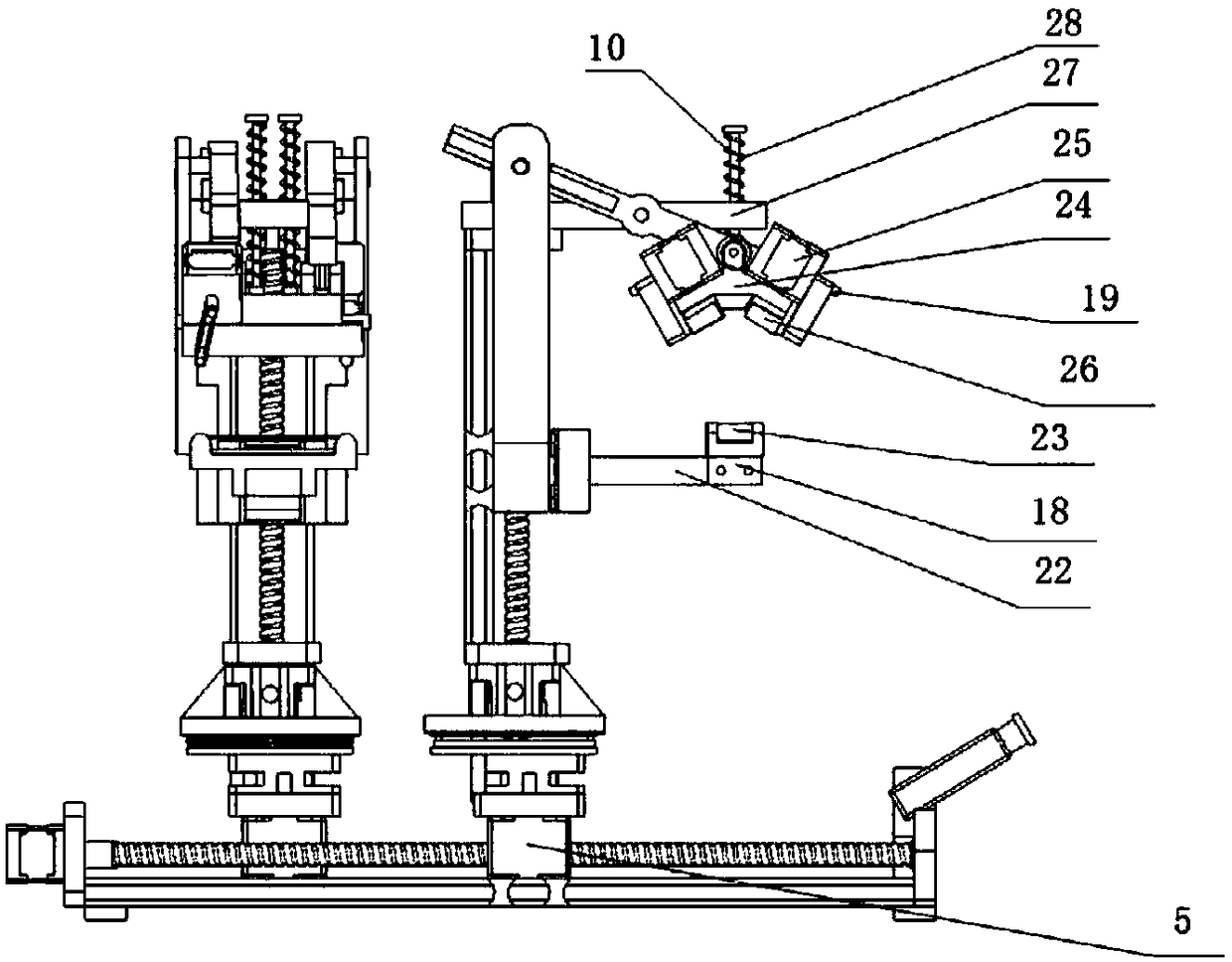

[0021] A high-voltage transmission line inspection robot of the present invention includes two robot monomers with the same structure, a frame, a binocular camera 8 and two symmetrically arranged linear modules with the same structure; the robot monomer is assembled on the frame , the frame includes a connecting plate 1 and a first linear module bottom plate 4 symmetrically arranged left and right, and the linear module includes a flange 3, a first linear module bottom plate 4, a slider 5, a first lead screw 6 and The first drive motor 7, the flange 3 is fixedly connected with the first linear module base plate 4, the first lead screw 6 is assembled on the first linear module base plate 4, and the slider 5 is assembled on the first wire On the bar 6, the first drive motor 7 is connected to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com