An automatic dipping equipment for fixture production

A fixture and equipment technology, applied in the field of automatic dip molding equipment for fixture production, can solve problems such as low dip molding production efficiency, and achieve the effects of improving stability and safety, high degree of automation, and synchronous and efficient transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

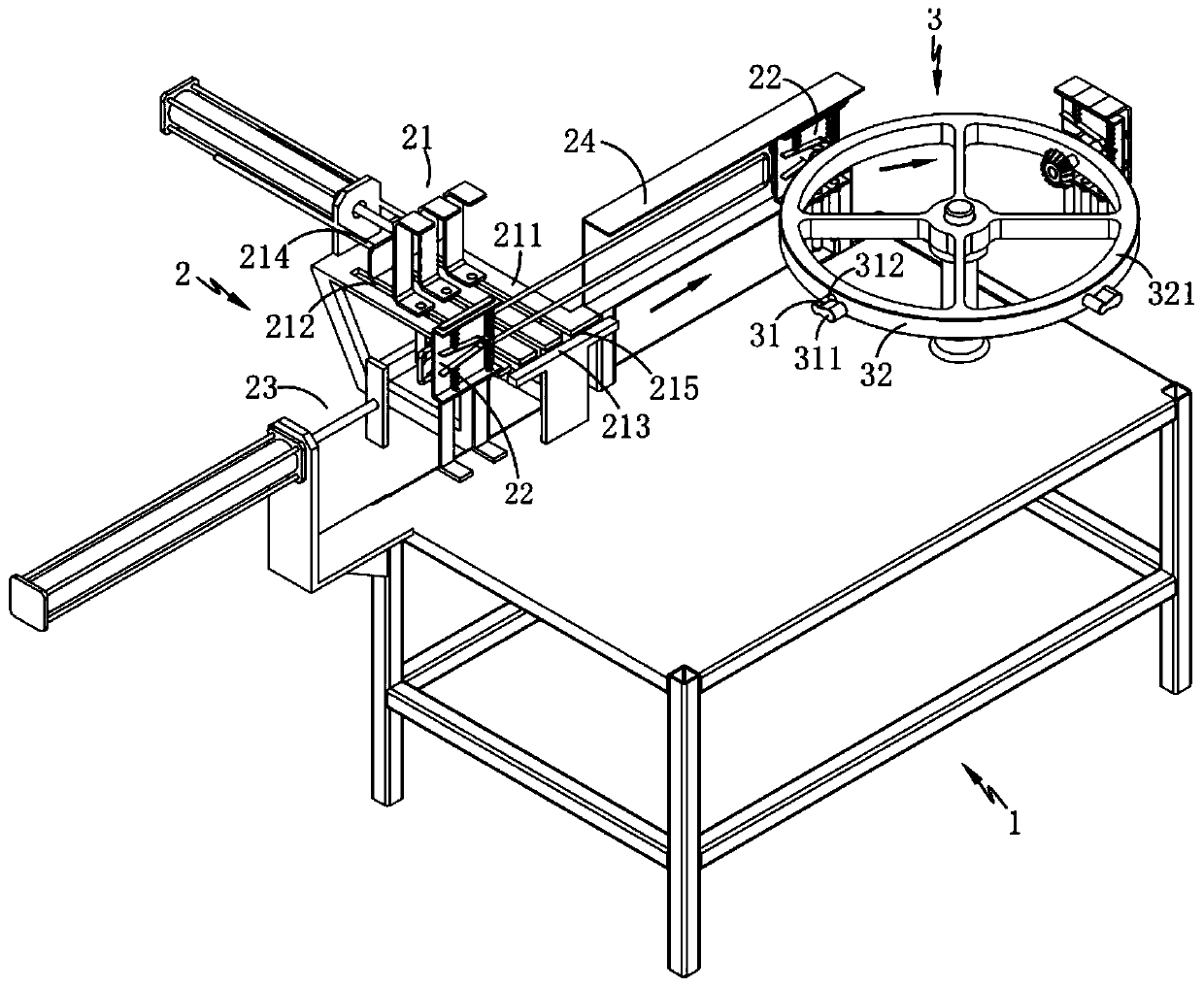

[0034] Such as figure 1 , 2 As shown in and 3, an automatic dipping equipment for fixture production, including frame 1, also includes:

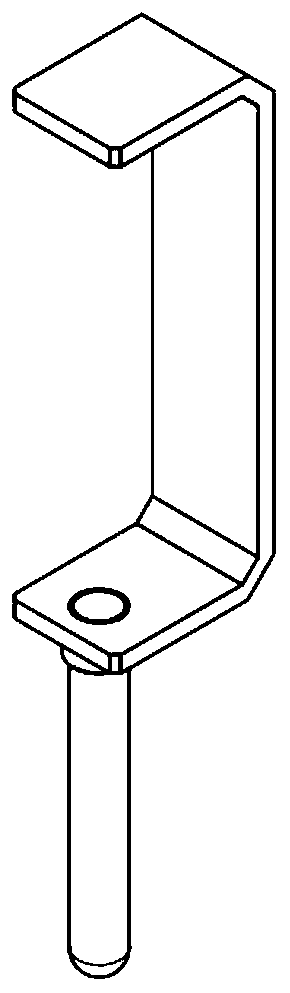

[0035] Feeding mechanism 2, the feeding mechanism 2 is arranged on the frame 1, which respectively includes a batching assembly A21 for transferring the parts to be dipped, a clamping assembly 22 for fixing the parts to be dipped, and a The batching assembly B23 conveyed by the clamping assembly 22 and the limiting assembly 24 for limiting and guiding the clamps and tooling; structure; and ...

Embodiment 2

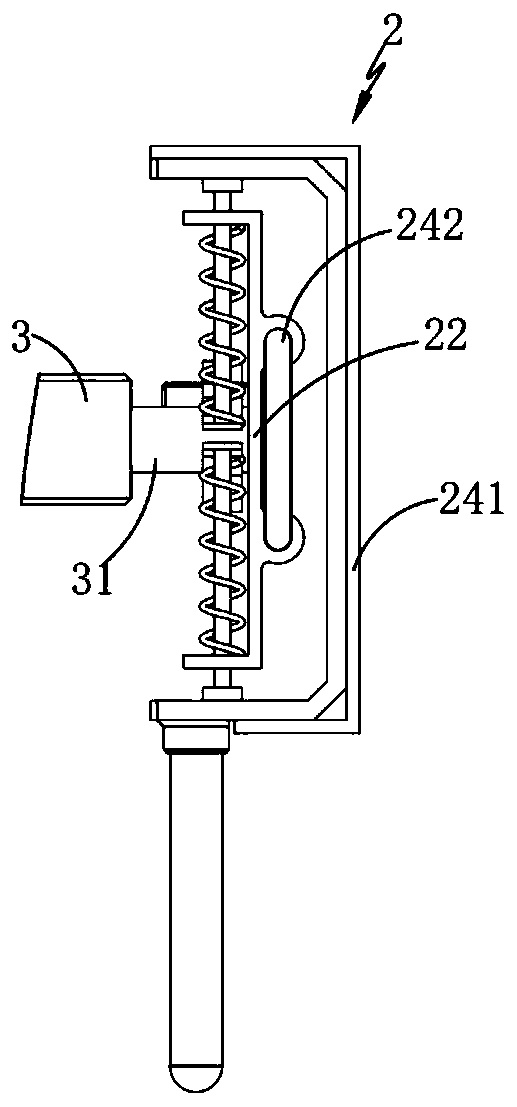

[0041] Such as figure 1 with 6 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that: the guide rod 242 is fixedly arranged on the frame 1, one end of which extends outside the limiting groove 241, and forms a gap between the feeding part 231 and the clamping assembly 22. The loading space 240; the clamping assembly 22 is positioned by the guide rod 242 extending to the outside of the limiting groove 241, so as to realize the partition entry of the two production materials and the subsequent synchronous transfer, thereby realizing the orderly and stable operation of the present invention.

[0042] Further, as figure 1 , 3 , 7, 8 and 9, the clamping assembly 22 is inside the part to be impregnated, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com