Mini-type guide missile fuse

A missile fuze and fuze technology, applied in the field of fuze, can solve problems such as difficult to meet the requirements of missile electronic control, acceleration inertia, etc., and achieve the effect of fast disassembly and maintenance, lightening mass load and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

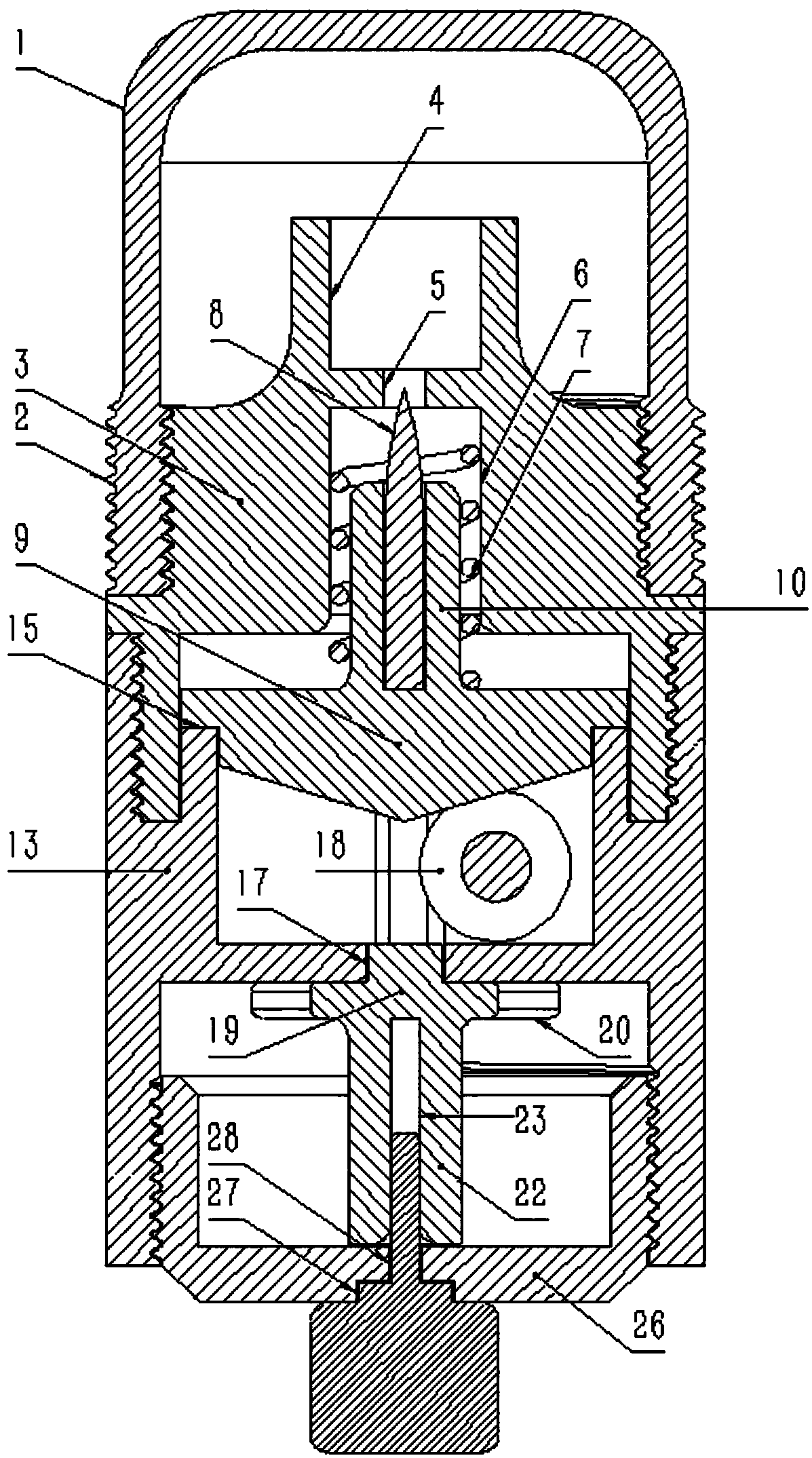

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0035] like Figure 1-3 As shown, a miniature missile fuze of the present invention includes a fuze body, a firing pin seat 3 arranged in the fuze body, a firing pin body 9, a firing pin spring 7, a firing pin 8, a firing pin cover 10 and a lock 19 , and the fuze cover 26 and the safety bolt 30; the expansion chamber casing 1, the safety chamber casing 13, the fuze cover 26, the firing pin body 9, the firing pin seat 3 and the locker 19 are all formed by photocuring 3D printing of resin material.

[0036] The fuze body includes an explosion chamber housing 1 and an insurance chamber housing 13, the explosion chamber housing 1 and the insurance chamber housing 13 are cylindrical, the top end is closed, the bottom end is open, and the bottom of the explosion chamber housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com