A digital differential tension sensor based on a linear array CCD and a tension detection method using the sensor

A tension sensor and tension detection technology, applied in the field of sensors, can solve the problems of reduced service life of the sensor, weak ability to resist transient impact, damage of the sensor, etc., and achieve the effect of simple driving sequence, prolonging the service life and small dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

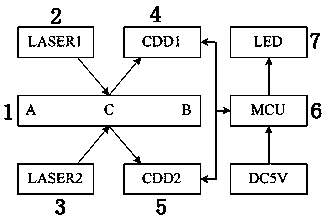

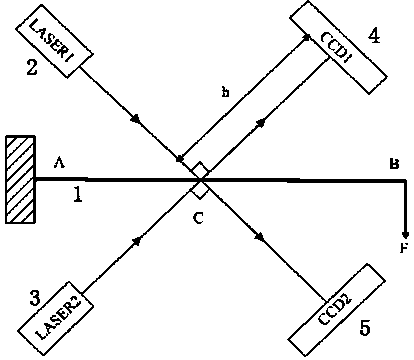

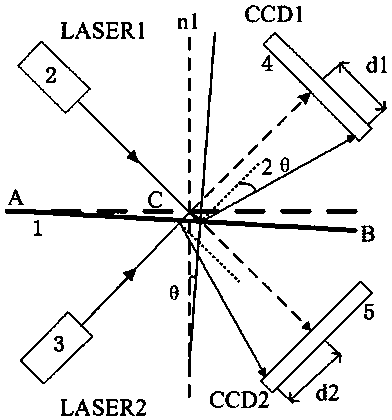

[0028] With reference to the accompanying drawings, the digital differential tension sensor based on the linear array CCD of the present invention includes a suspension beam 1 made of elastic material, the inner end of the suspension beam 1 is fixed, the front and back sides of the middle part are respectively provided with mirror reflection areas, and the outer end is free to bear force. end. A first laser emitter 2 and a second laser emitter 3 are arranged symmetrically above and below the inner end of the suspension beam 1. The optical paths of the two laser emitters are arranged obliquely and facing the mirror reflection area. The light-reflecting first linear CCD element 4 and the second linear CCD element 5 , the signal output ends of the two linear CCD elements are electrically connected to a control circuit 6 . Wherein, the specular reflection area is used to reflect laser light, and the specular reflection area can be formed by attaching a reflective layer on the fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com