Special rail robot for charging pile inspection

A technology of orbital robots and inspection robots, which is applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problem of heavy inspection work of charging piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

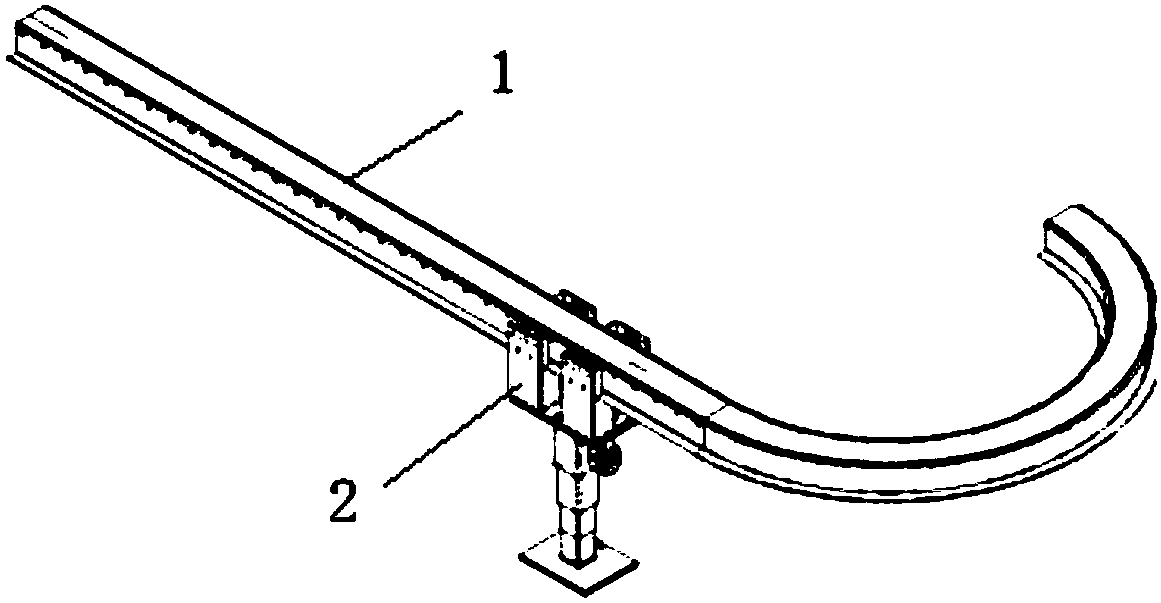

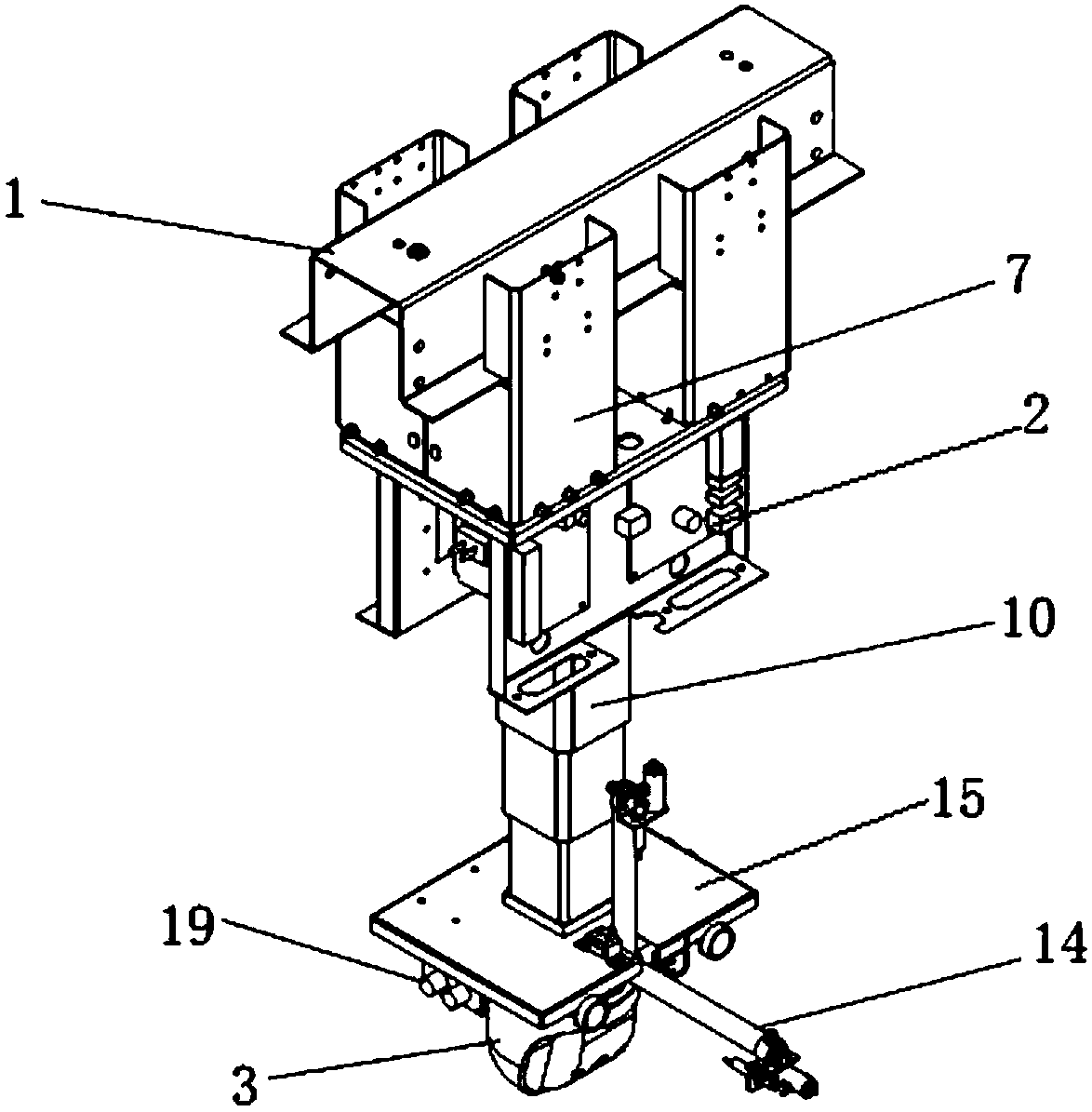

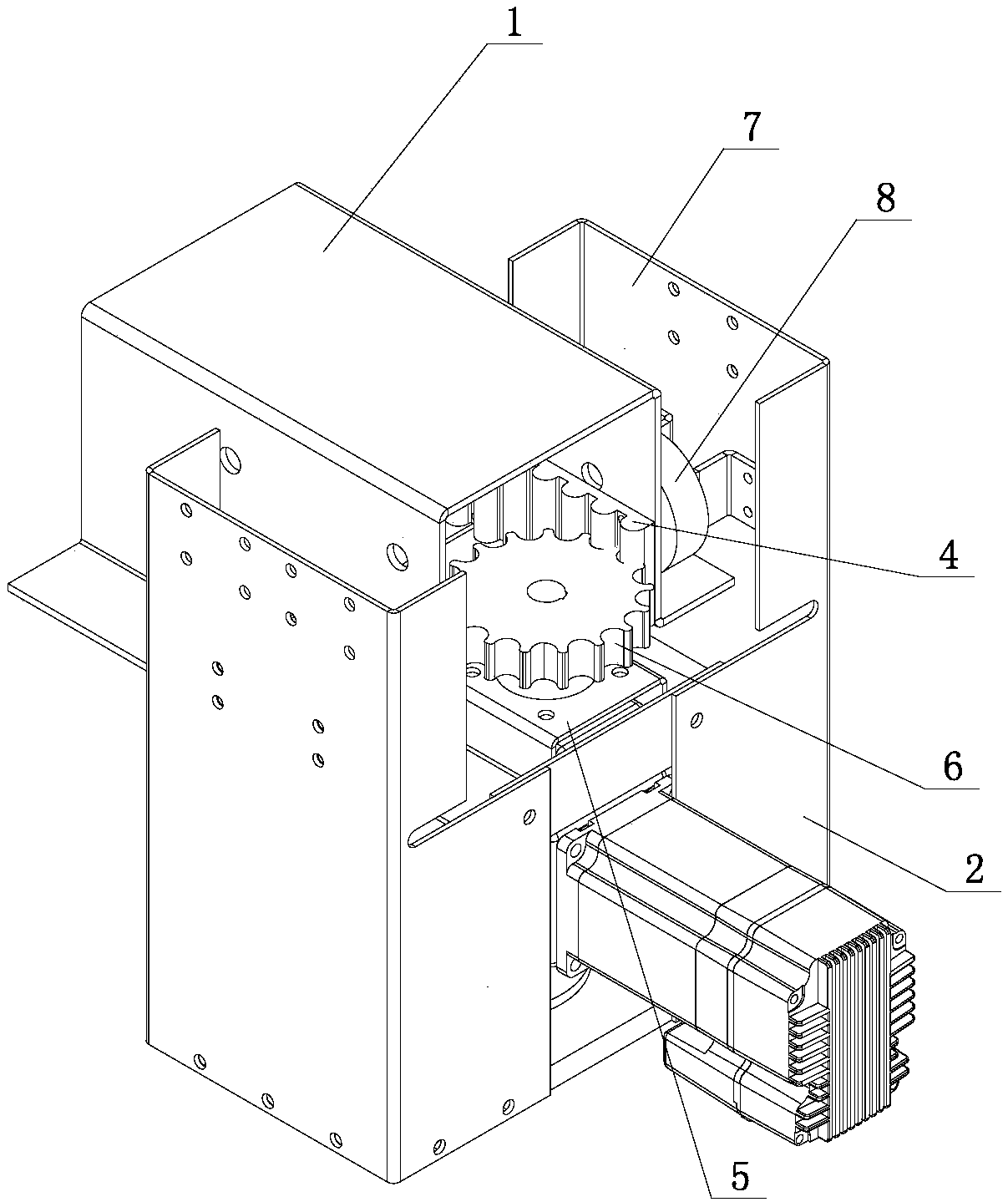

[0024] Such as Figure 1-5 As shown in , a special rail robot for charging pile inspection, including a "Ji"-shaped track 1 with a cross-section in the shape of "Ji", and walking on the "Ji"-shaped track 1 along the length direction of the "Ji"-shaped track 1 through a walking mechanism. The inspection robot at the lower part of the track 1, the inspection robot includes a robot body 2, a lifting mechanism located at the bottom of the robot body 2, the tail end of the lifting mechanism is provided with a touch screen card swiping mechanism, a high-speed spherical pan-tilt camera 3, and a high-speed The spherical pan-tilt camera 3 wirelessly communicates with the controller in the background, and the wireless control of the controller connects the travelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com