High-power circulator shell and high-power circulator

A circulator, high-power technology, applied in waveguide-type devices, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of difficult control of welding deformation, low cooling efficiency of rotating ferrite, affecting the performance of microwave power, etc. Achieve the effect of improving cooling efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

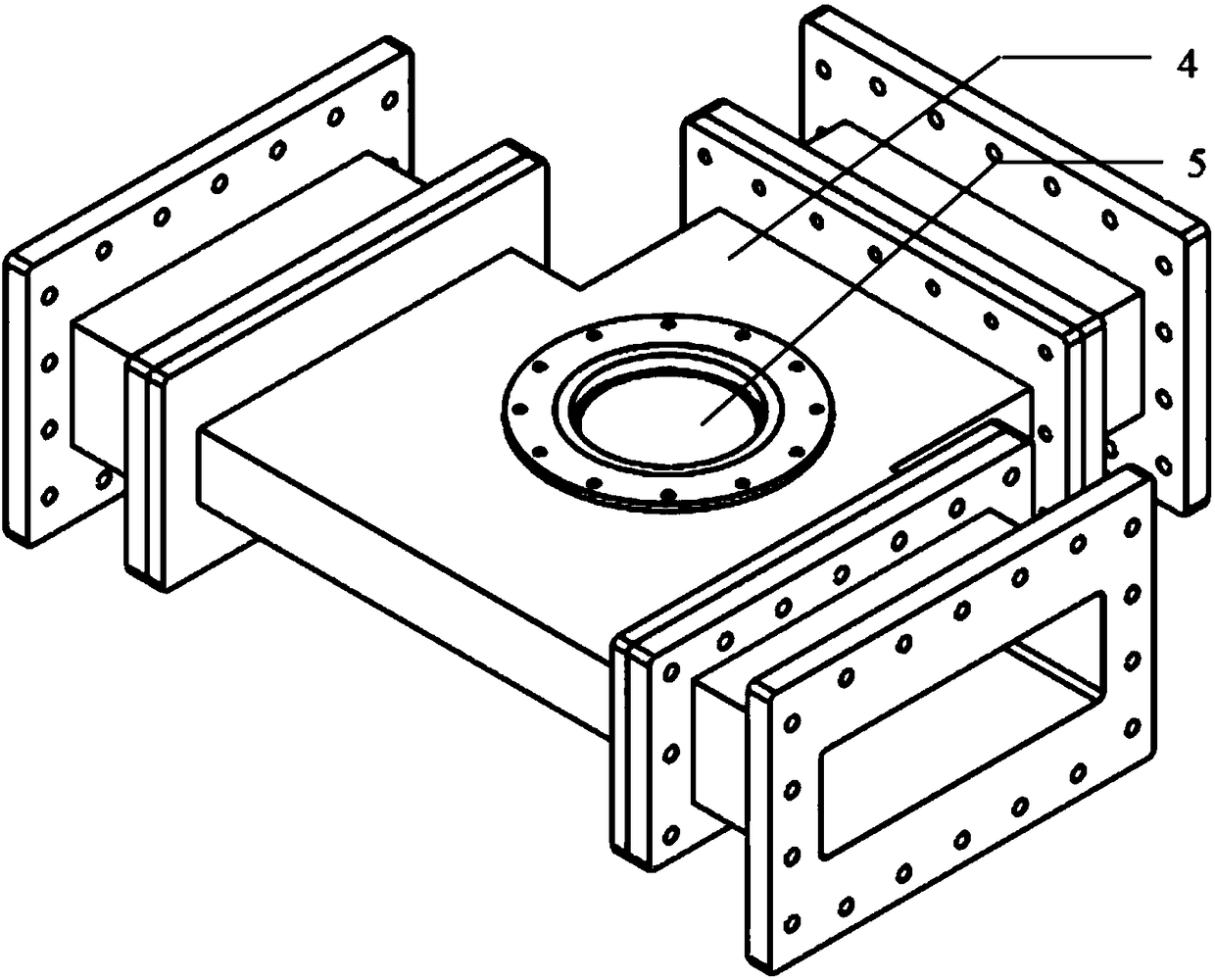

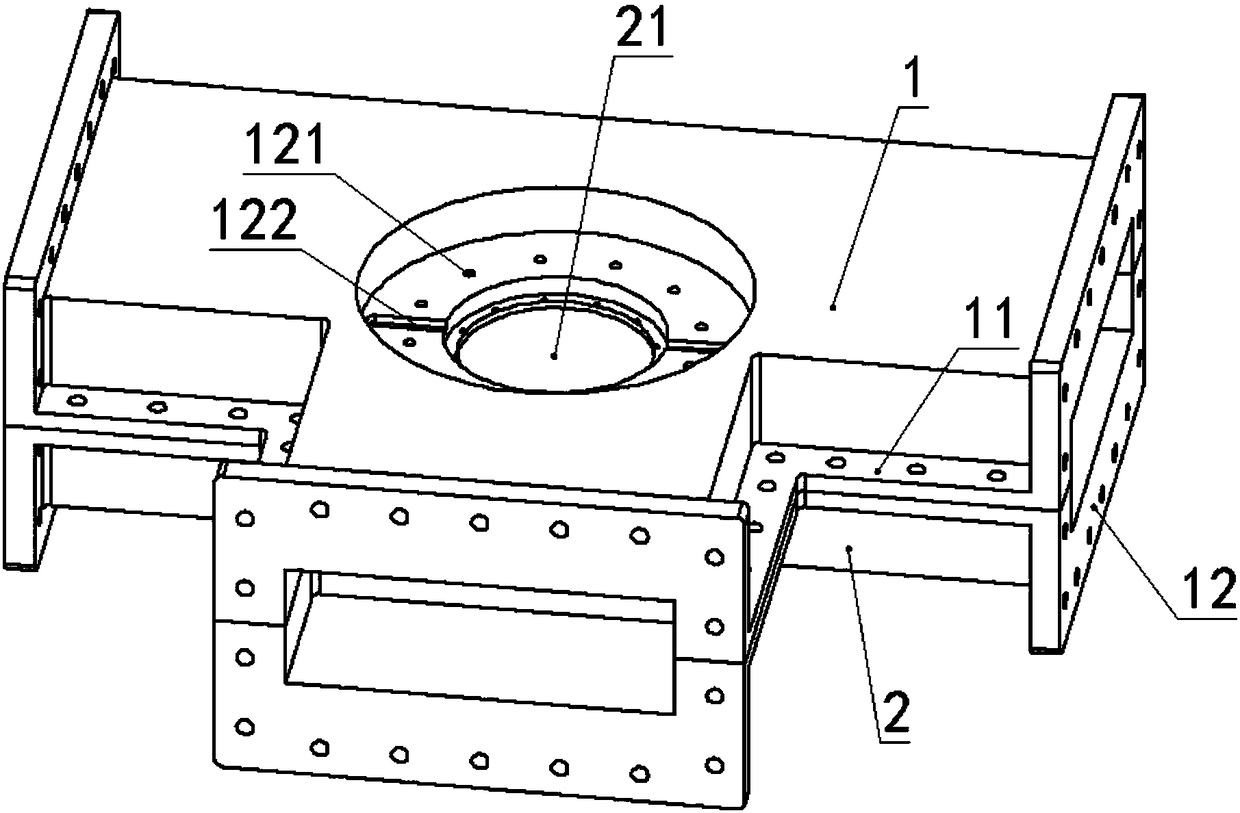

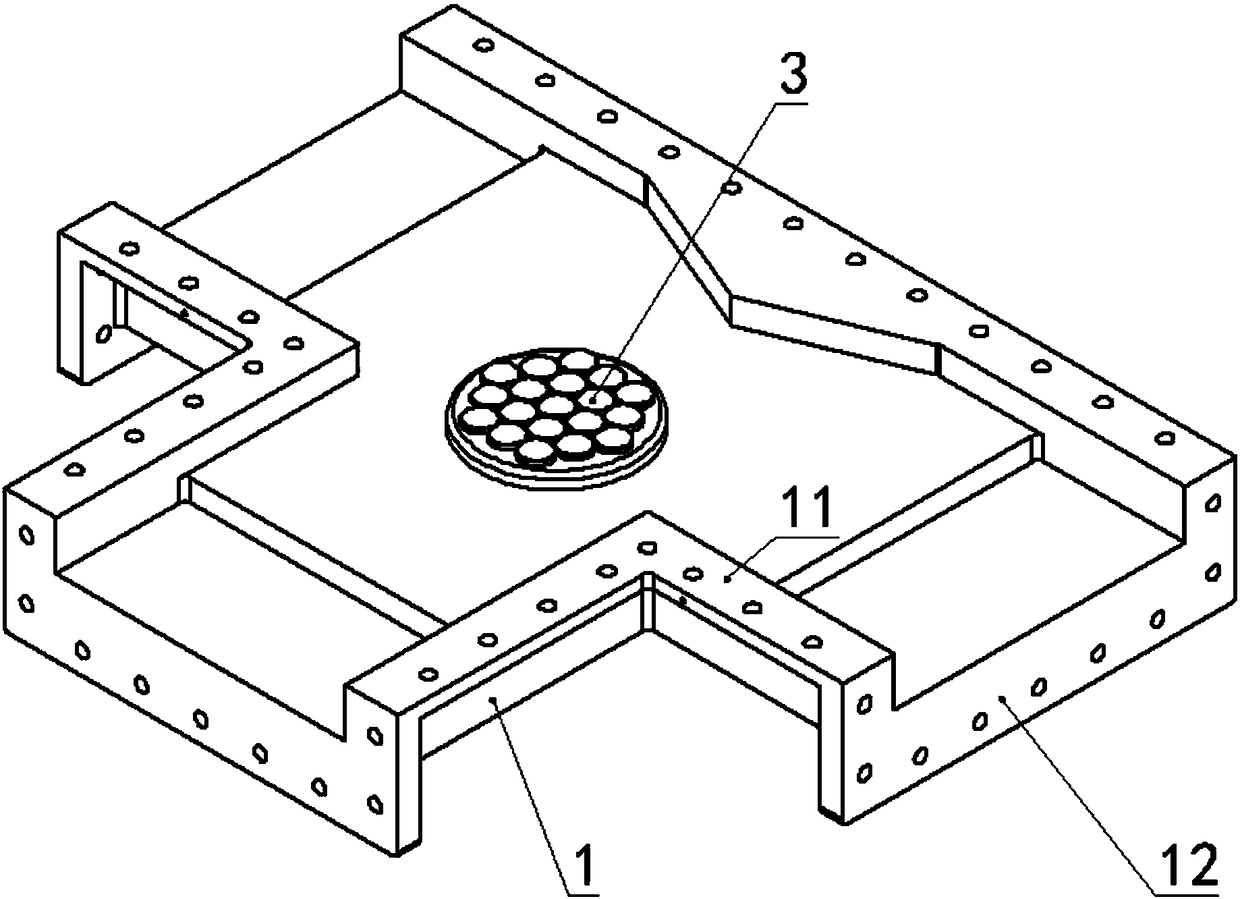

[0021] Such as figure 1 As shown, the current processing method commonly used for high-power circulator shells is to weld multiple aluminum plates or copper plates. The welding deformation is large and difficult to control. During use, the rotating ferrite needs to be replaced frequently. In the prior art, due to the The shell 4 is usually processed by welding, and the inside is closed. Therefore, in order to facilitate the replacement of the gyromagnetic ferrite in the prior art, the gyromagnetic ferrite is pasted on the water cooling plate, and then the gyromagnetic ferrite is placed along the circulator shell 4. The axial direction of the hole is put into the circulator housing 4, and then the water cooling plate 5 is connected to the circulator housing 4 by screws. In the practical application of high-power microwave power supply, the water cooling plate 5 and the circulator The installation gap between the shells 4 will produce sparks, which will seriously affect the perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com