High-voltage dry type insulated power cable equipment terminal

A technology for dry insulation and power cables, which is applied in the installation of cable terminals, cable accessories, and cables. Retraction, the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

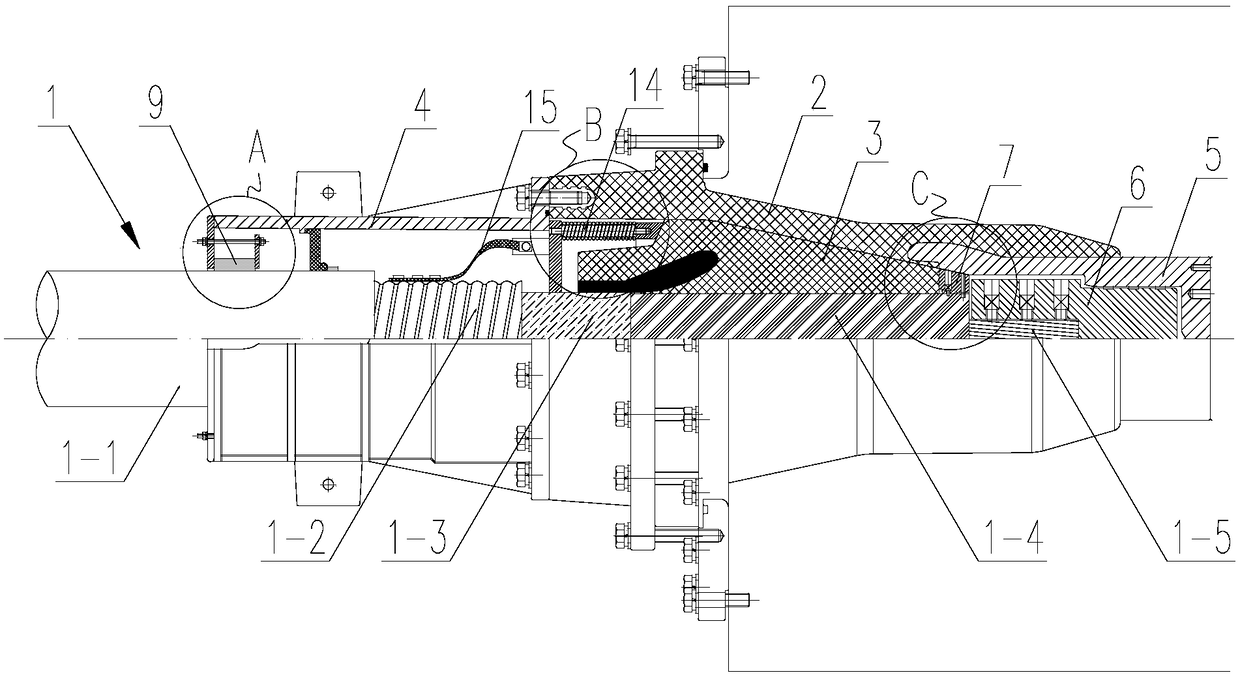

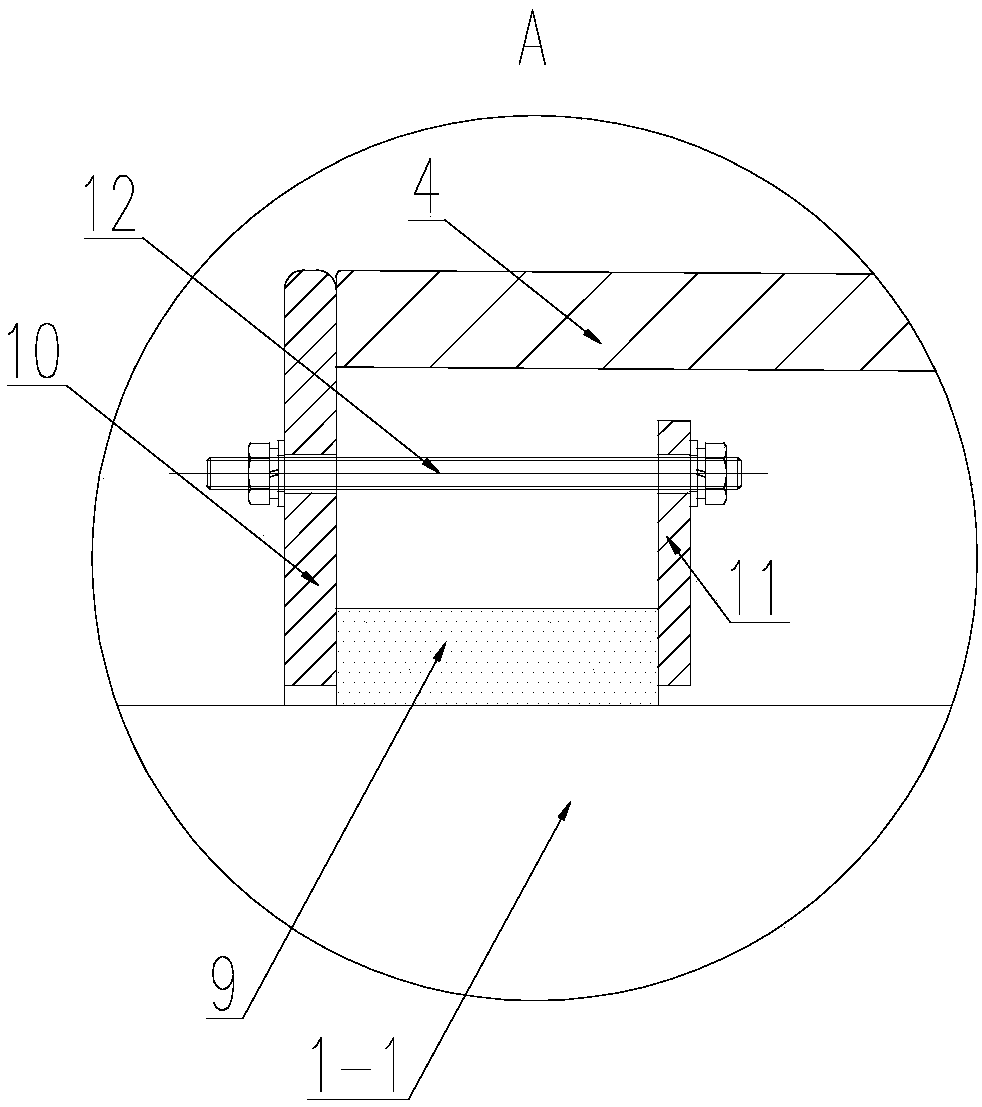

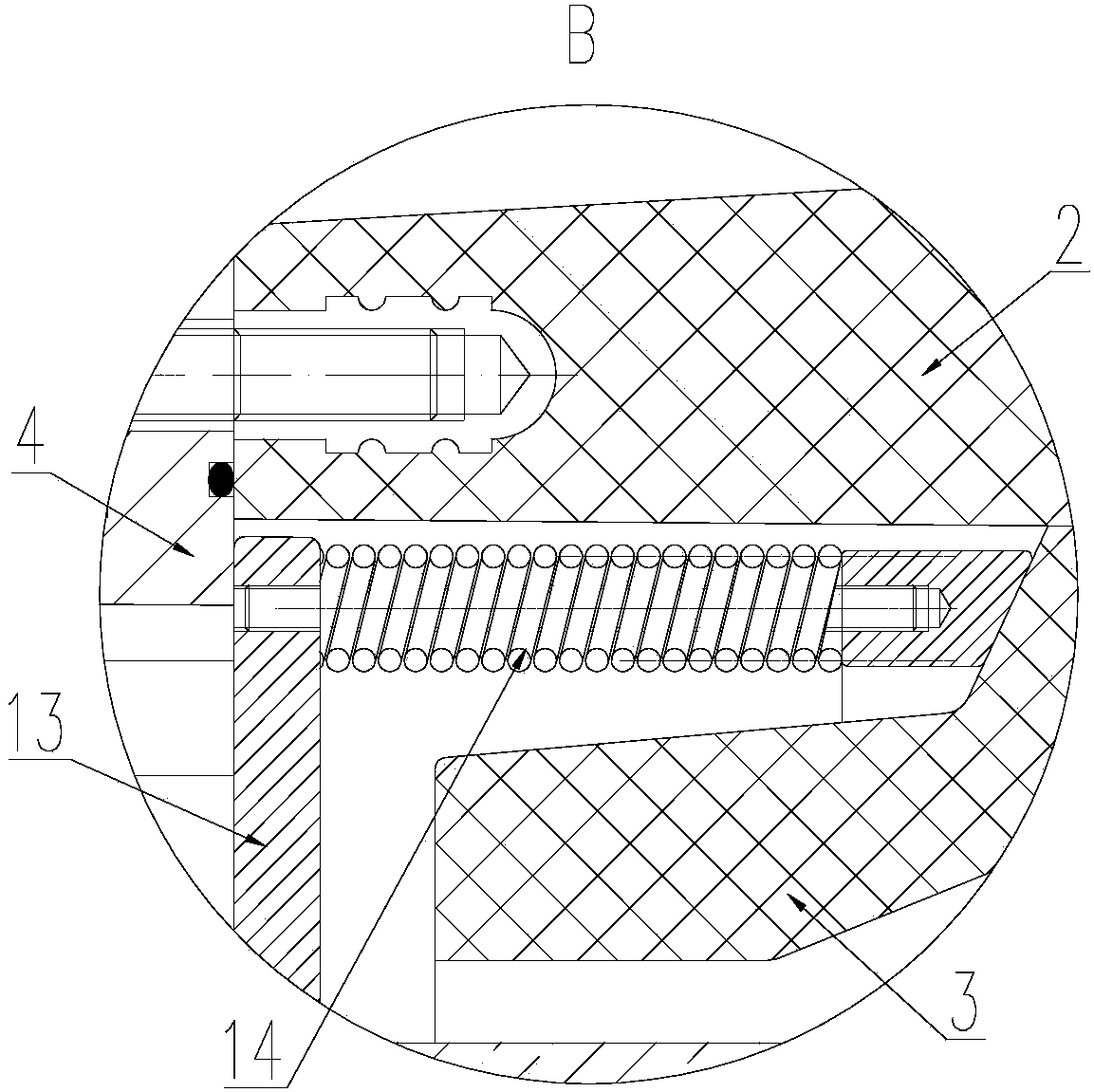

[0025] Such as Figure 1-4 As shown, a high-voltage dry-type insulated power cable equipment terminal includes an insulating bushing 2, a stress cone 3 arranged in the insulating bushing 2, a tail pipe 4 arranged at the inlet end of the insulating bushing 2, and a tail pipe 4 arranged in the insulating bushing 2. The connecting fitting 5 at the outlet end and the connecting contact 6 arranged in the connecting fitting 5, the tail pipe 4 and the connecting fitting 5 are respectively fixed at both ends of the insulating sleeve 2;

[0026] The cable 1 passes through the tail pipe 4 and the insulating sleeve 2, a section of the exposed core section 1-5 is exposed at the front end of the cable 1, and an exposed section 1 of the insulating layer is exposed on the part of the cable 1 adjacent to the exposed section 1-5 of the core -4;

[0027] Such as Figure 4 As shown, the core exposed section 1-5 is fixed in the connecting contact 6, the stress cone 3 is sleeved on the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com