Automatic detection method and device of SDI chip, storage medium and terminal

An automatic detection device and automatic detection technology, applied in television, electrical components, image communication, etc., can solve problems such as low efficiency, long time-consuming SDI chips, unfavorable batch production of SDI chips, etc., to save time and cost, and improve screening efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

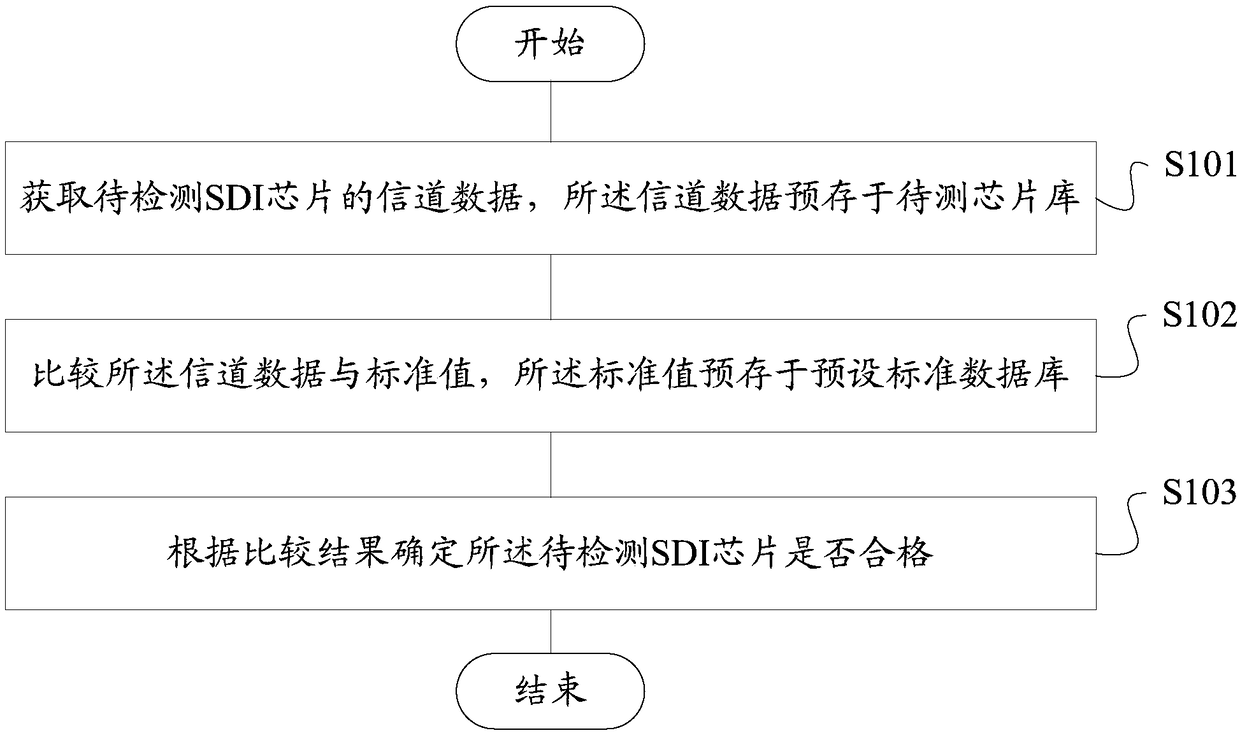

[0030] Those skilled in the art understand that, as stated in the background technology, in the prior art, when the digital component serial interface (SerialDigital Interface, referred to as SDI) chip is inspected at the factory, it is necessary to manually compare the items to be tested of each SDI chip one by one. , takes a long time and has low efficiency, which is not conducive to the mass production of SDI chips.

[0031] For example, according to the existing test plan, it is necessary to manually measure and monitor the level range of the SDI signal on a high-definition oscilloscope, and to check the amplitude and signal quality of the output signal through an eye diagram. The serial peripheral interface (Serial Peripheral Interface, referred to as SPI) reads the current frame rate of the 4-channel image in real time, and observes the image display and frame loss of multiple interfaces. The entire detection process is time-consuming and inefficient.

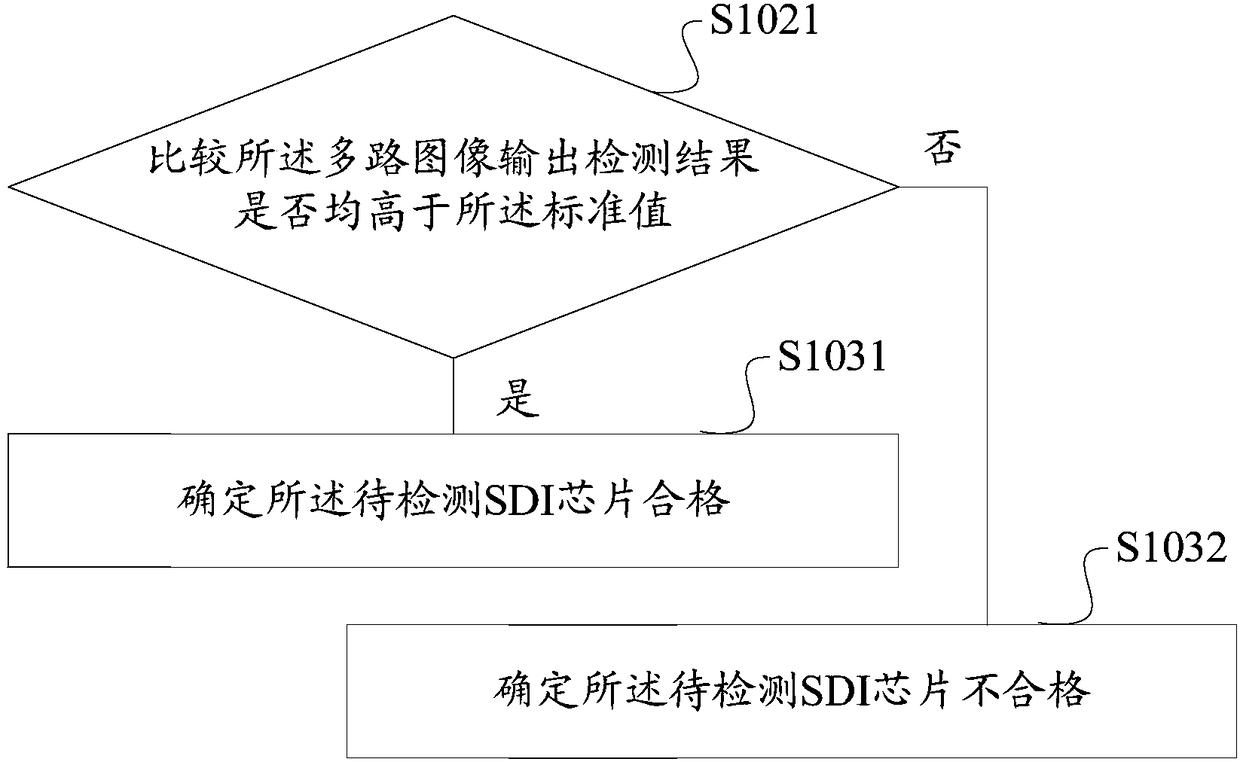

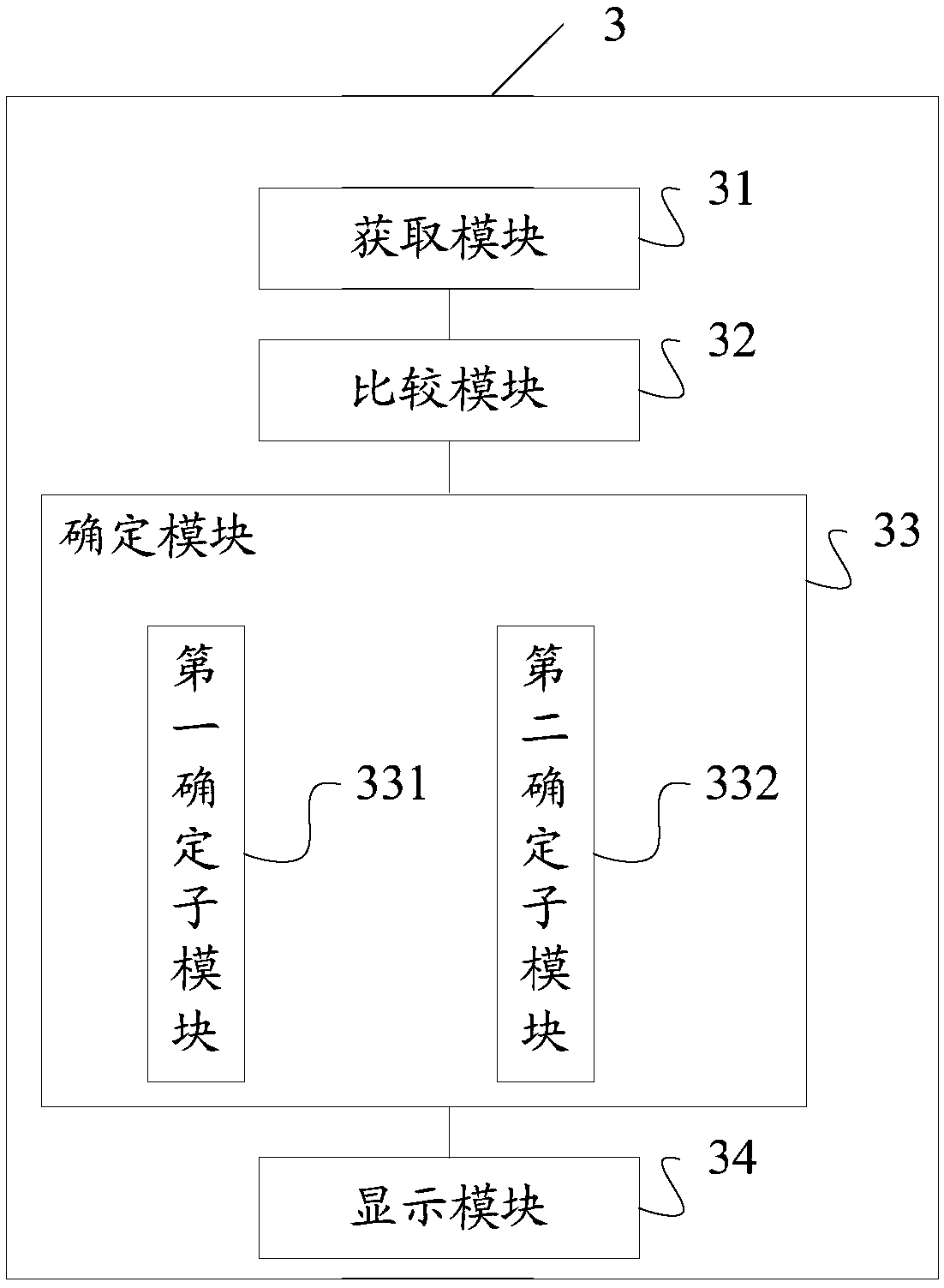

[0032] In order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com