Baby milk powder of which micro functional active components in formula are comprehensively adjusted and preparation method of baby milk powder

A technology of infant milk powder and functional activity, which is applied in the direction of milk preparations, dairy products, applications, etc., and can solve the problems of comprehensively improving trace functional active components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

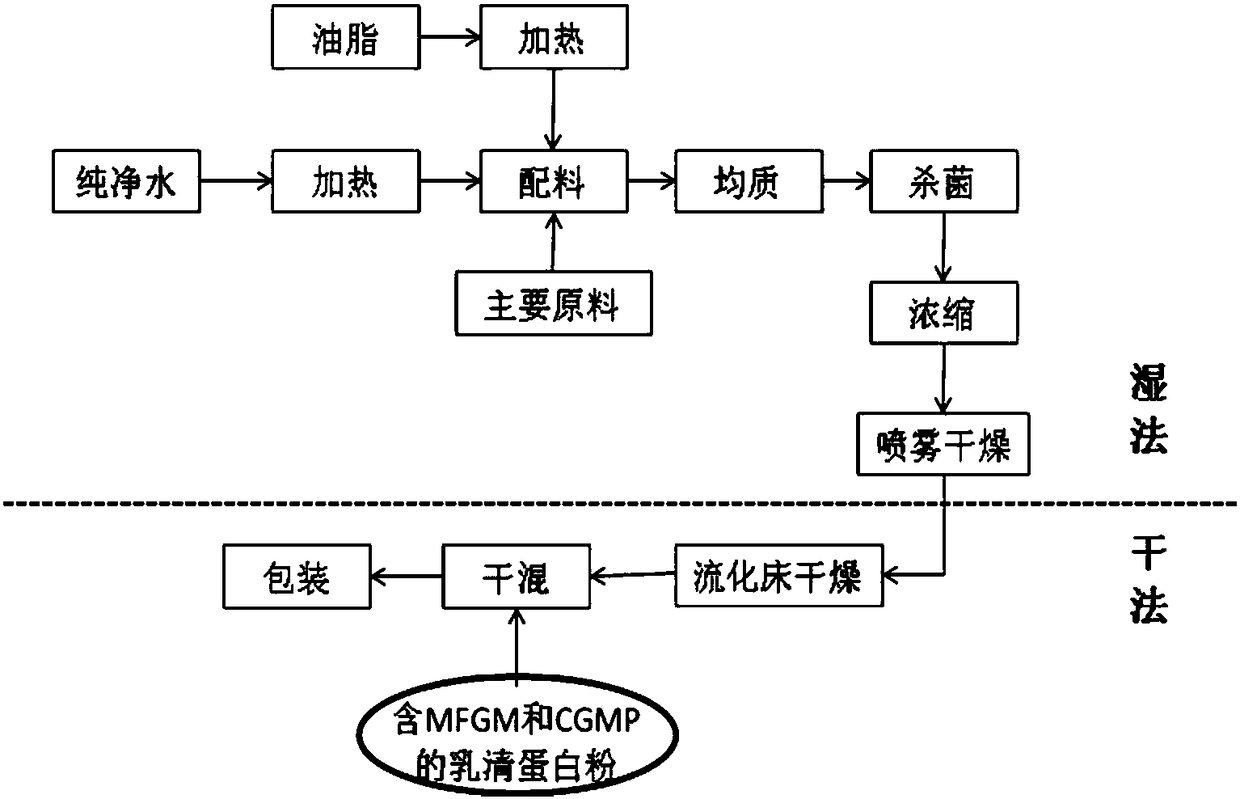

Method used

Image

Examples

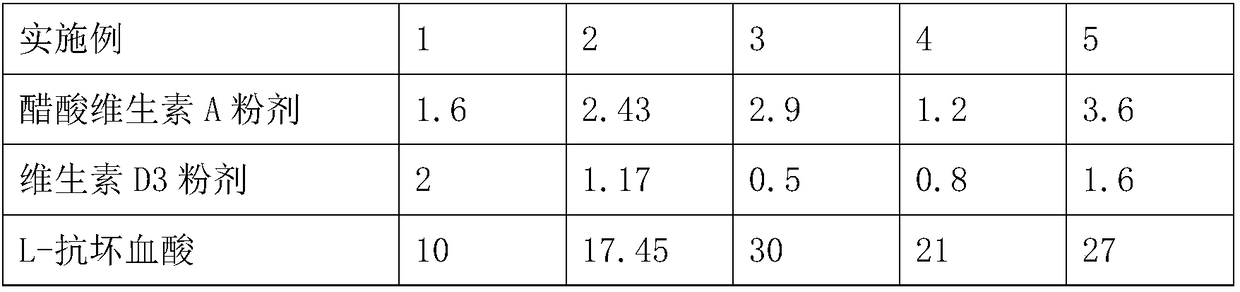

Embodiment 1

[0063] (1) Put desalted whey powder, skimmed milk powder, lactose, galacto-oligosaccharide, and fructo-oligosaccharide into purified water heated to 40°C in proportion to obtain a water mixture;

[0064] (2) Premixing OPO structured fat and refined vegetable oil in proportion and then heating to 65°C to obtain an oil mixture;

[0065] (3) Mix the water mixture obtained in step (1) with the oil mixture obtained in step (2), homogenize under a pressure of 200 bar and cool to 0° C.;

[0066] (4) Add compound vitamins and compound minerals in a proportioning amount, stir evenly, sterilize at 95°C for 90 seconds, concentrate at 70°C, spray dry, and then dry in a fluidized bed to obtain base powder. The air inlet temperature of the spray drying is 215°C, the exhaust air temperature is 70°C, the temperature of the fluidized bed sections I, II, and III in the fluidized bed drying process is 15°C, and the temperature of the fluidized bed section IV is 40°C;

[0067] (5) dry-mix the ba...

Embodiment 2

[0070] (1) Put desalted whey powder, skimmed milk powder, lactose, galacto-oligosaccharide, and fructo-oligosaccharide into purified water heated to 60°C in proportion to obtain a water mixture;

[0071] (2) Premixing OPO structured fat and refined vegetable oil in proportion and then heating to 60°C to obtain an oil mixture;

[0072] (3) Mix the water mixture obtained in step (1) with the oil mixture obtained in step (2), homogenize under a pressure of 150 bar and cool to 4° C.;

[0073] (4) Add compound vitamins and compound minerals in a proportioning amount, stir evenly, sterilize at 88°C for 35 seconds, concentrate at 86°C, spray dry, and then dry in a fluidized bed to obtain base powder. The air inlet temperature of the spray drying is 200°C, the exhaust air temperature is 80°C, the temperature of the fluidized bed section I, II, and III in the fluidized bed drying process is 85°C, and the temperature of the fluidized bed section IV is 35°C;

[0074] (5) Dry-mix the bas...

Embodiment 3

[0082] (1) Put desalted whey powder, skimmed milk powder, lactose, galacto-oligosaccharide, and fructo-oligosaccharide into purified water heated to 65°C in proportion to obtain a water mixture;

[0083] (2) Premixing OPO structured fat and refined vegetable oil in proportion and then heating to 40°C to obtain an oil mixture;

[0084] (3) Mix the water mixture obtained in step (1) with the oil mixture obtained in step (2), homogenize under a pressure of 100 bar and cool to 6° C.;

[0085] (4) Add compound vitamins and compound minerals in a proportioning amount, stir evenly, sterilize at 75°C for 20 seconds, concentrate at 90°C, spray dry, and then dry in a fluidized bed to obtain base powder. The air inlet temperature of the spray drying is 180°C, the exhaust air temperature is 90°C, the temperature of the fluidized bed sections I, II, and III in the fluidized bed drying process is 95°C, and the temperature of the fluidized bed section IV is 15°C;

[0086] (5) Dry-mix the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com