Washing device for large hard food material processing

A cleaning device, a hard technology, applied to the cleaning method using tools, the cleaning method using liquid, cleaning methods and utensils, etc., can solve the problems of insufficient cleaning and time-consuming, etc., and achieve simple structure and convenient use , cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

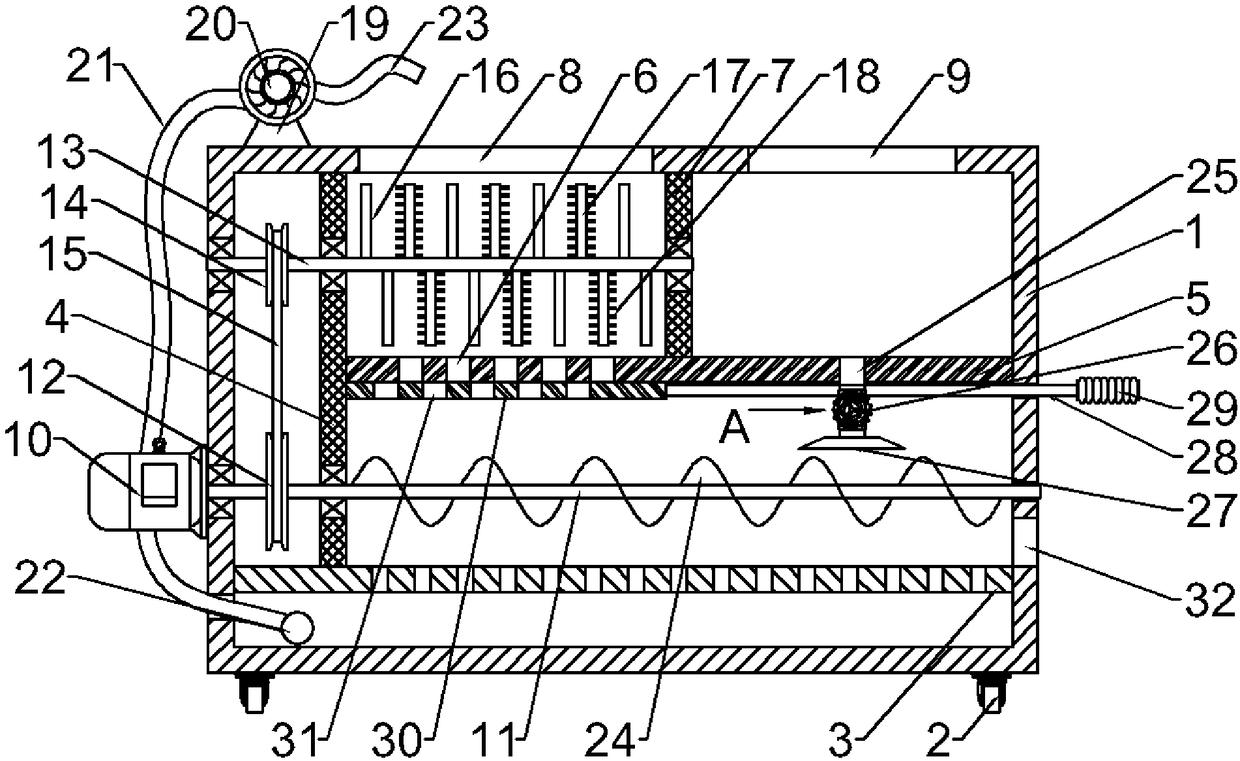

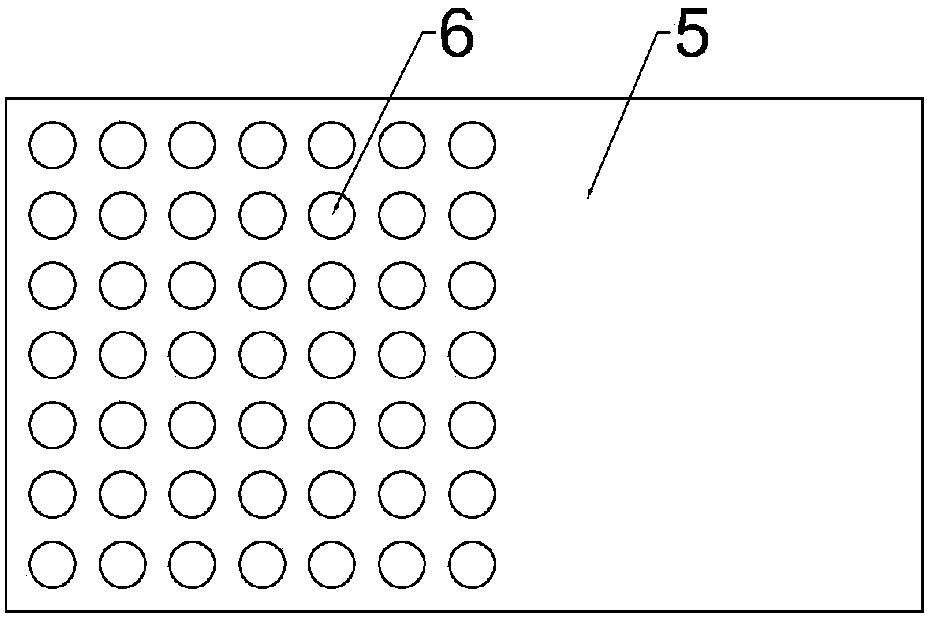

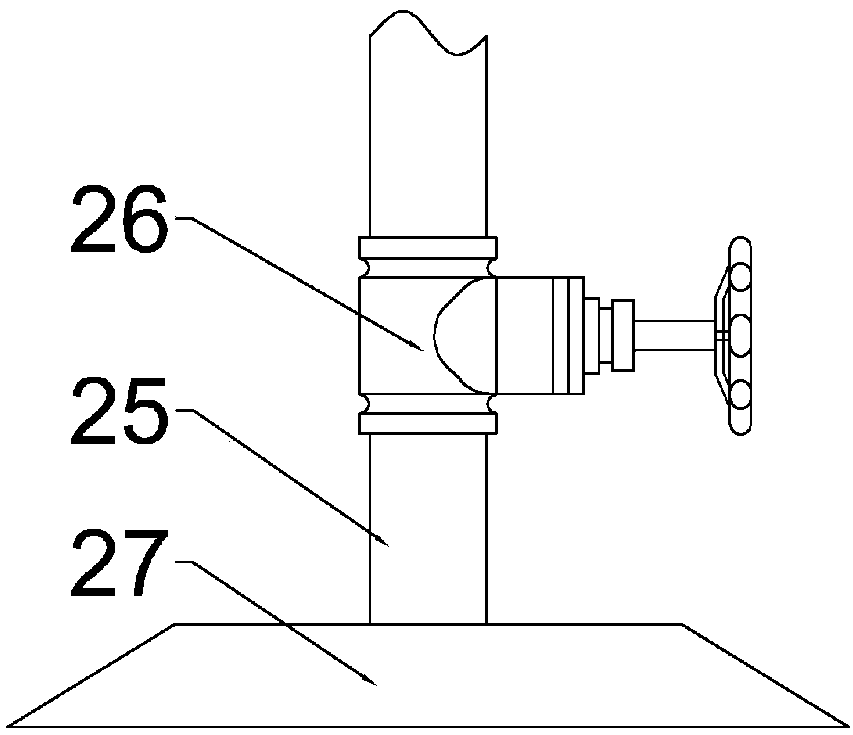

[0021] see Figure 1-3 , a cleaning device for processing large-scale hard food materials, comprising an outer casing 1, a perforated filter plate 3 is fixedly connected to the bottom of the outer casing 1, and a longitudinal partition plate is fixedly connected to the upper left side of the punched filter plate 3 4. The middle part on the right side of the longitudinal partition plate 4 is vertically fixedly connected with a grading partition 5, and the lower left side of the grading partition 5 is provided with a number of first-level discharge openings 6, and the middle part above the grading partition 5 is vertically fixedly connected with a water tank baffle 7. The water tank baffle 7 is located on the right side of the first-level discharge port 6;

[0022] Turn on the motor 10 during use, and add cleaning water on the right side of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com