Multifunctional wood splitting operating table

A multi-functional, operating table technology, which is applied in the direction of wood processing equipment, circular saws, sawing components, etc., can solve the problems of affecting the flatness of wood cutting, large vibration of the cutting table, and low efficiency, so as to improve the cutting effect and cutting accuracy , Good clamping effect, accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

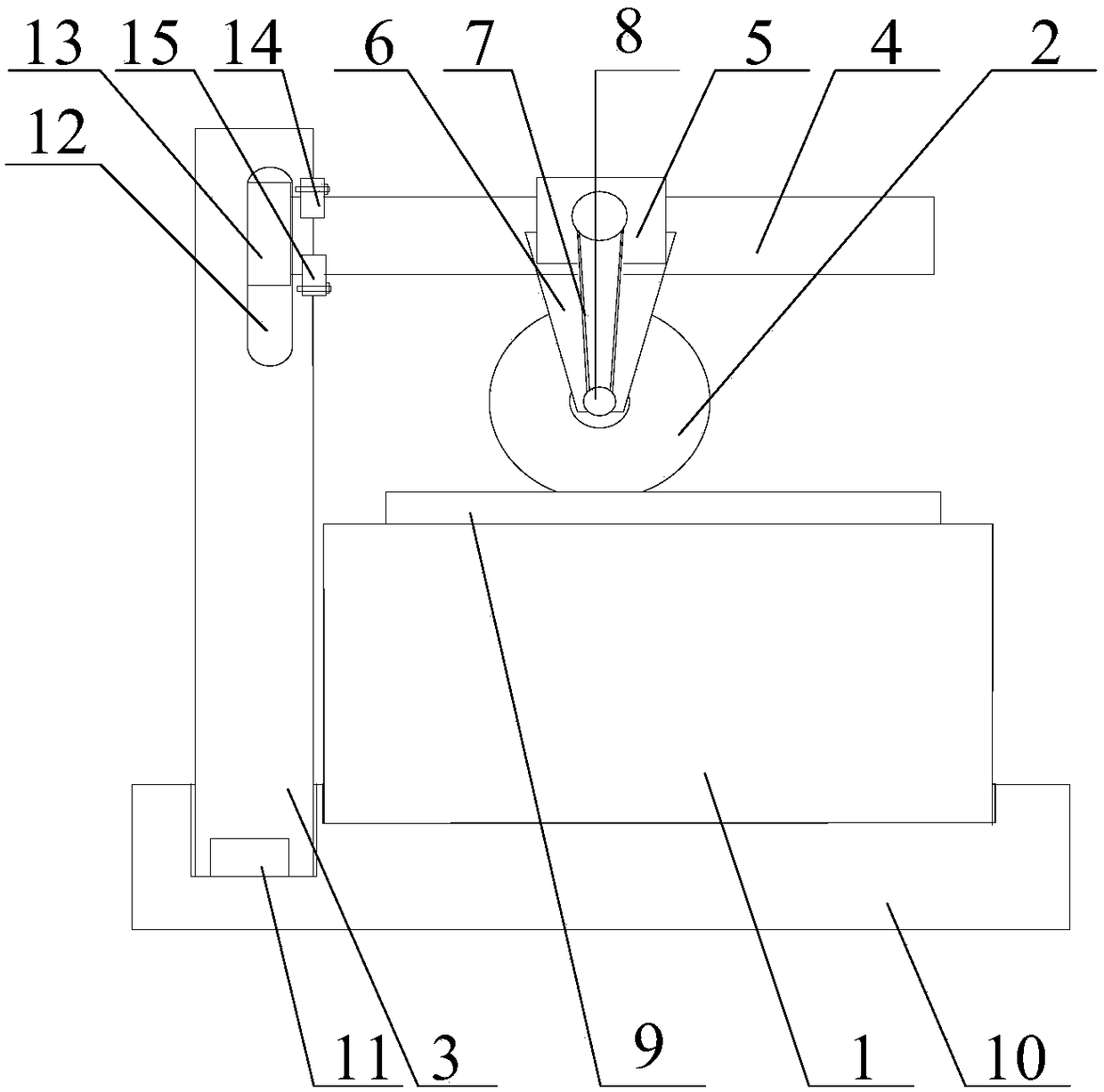

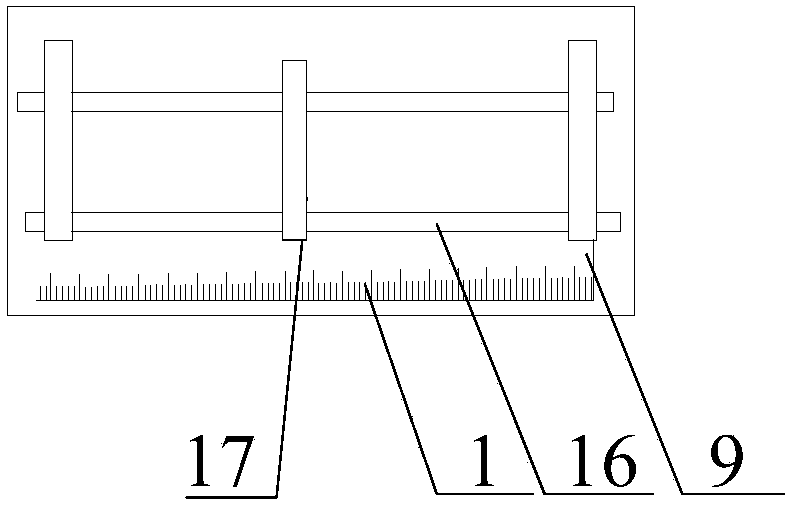

[0021] Such as figure 1 , 2 As shown, the multi-functional wood segmentation operation platform of the present invention includes a table 1, a circular saw disc 2, and also includes a column 3 and a transverse support 4. The column 3 is arranged on the side of the table 1, and the horizontal support 4 One end can move along the axial direction of the column 3 and is fixed to the column 3 through a fixed plate and mounting bolts. A drive motor 5, two support arms 6 and a pulley 7 are also arranged on the transverse support 4. The circular saw disc 2 is located in the transverse direction Directly below the support 4, one end of each support arm 6 is connected to the rotating shaft 8 on the circular saw disc 2, the other end is fixed to the transverse support 4, one end of the pulley 7 is connected to the output shaft of the drive motor 5, and the other end is connected to the circular saw The rotating shaft 8 on the disc 2 is connected; two parallel grooves 16 and a cutting op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com