A kind of high temperature resistant tempered glass and preparation method thereof

A technology of tempered glass and high temperature resistance, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc. It can solve the problems of tempered glass such as easy warping, weak high temperature resistance, high product defective rate, etc., and achieve good tempering effect , Improve high temperature resistance and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

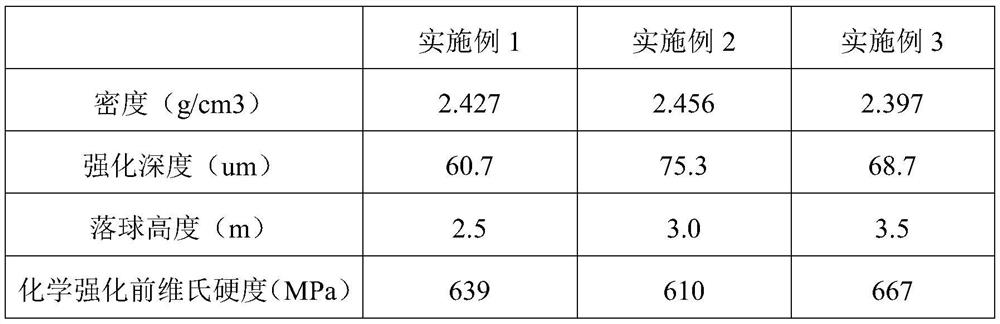

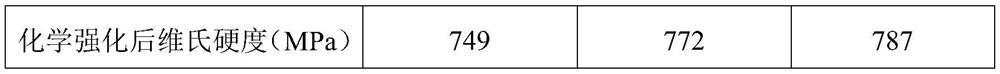

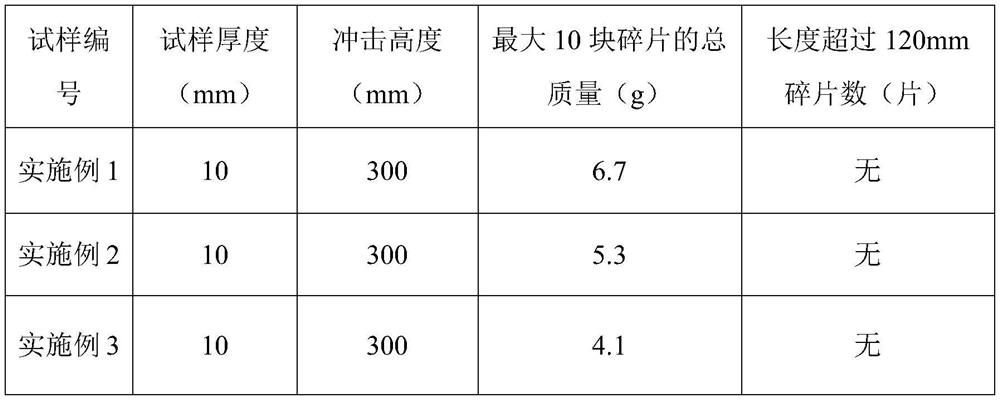

Embodiment 1

[0036] This embodiment provides a method for preparing high-temperature-resistant tempered glass, including the following sequential steps:

[0037] Step 1. Preparation of high temperature resistant material components: 50g silica sol, 20g potassium silicate water glass, 1g kaolin, 20g alumina, 10g zinc oxide, 3g bentonite, 5g calcium silicate, 40g water are evenly mixed, then ball milled and crushed. 200-mesh sieve, pour into 200ml deionized water, stir evenly, and obtain high-temperature-resistant material components;

[0038] Step 2. Preparation of silicate glass components: 500g of quartz sand, 100g of alumina, 100g of soda ash, 40g of Glauber's salt, 100g of dolomite, 30g of feldspar, 10g of wax stone, 30g of limestone, 10g of potassium metaborate, 1g of cerium oxide, 0.5g of nitrate, 0.5g of sulfate, 10g of coloring agent, 100g of cullet, 10g of titanium oxide, 10g of antimony oxide, 5g of yttrium oxide and 150g of high temperature resistant component are evenly mixed, t...

Embodiment 2

[0042] This embodiment provides a method for preparing high-temperature-resistant tempered glass, including the following sequential steps:

[0043] Step 1. Preparation of high temperature resistant material components: mix 55g of silica sol, 22g of potassium silicate water glass, 3g of kaolin, 22g of alumina, 12g of zinc oxide, 4g of bentonite and 7g of calcium silicate, mix them evenly, pulverize them with a ball mill, and pass through a 200-mesh sieve , inject 45g of water and stir evenly to obtain high temperature resistant material components;

[0044] Step 2. Preparation of silicate glass components: 520g of quartz sand, 150g of alumina, 120g of soda ash, 50g of Glauber's salt, 120g of dolomite, 40g of feldspar, 20g of wax stone, 40g of limestone, 20g of potassium metaborate, and clarification of cerium oxide 4g of coloring agent, 20g of coloring agent, 130g of cullet, 20g of titanium oxide, 10g of antimony oxide, 5g of yttrium oxide and 180g of high-temperature-resistan...

Embodiment 3

[0048] This embodiment provides a method for preparing high-temperature-resistant tempered glass, including the following sequential steps:

[0049] Step 1. Preparation of high temperature resistant material components: 60g of silica sol, 25g of potassium silicate water glass, 5g of kaolin, 25g of aluminum oxide, 15g of zinc oxide, 5g of bentonite and 10g of calcium silicate are evenly mixed, pulverized by ball mill, and passed through a 200-mesh sieve , inject 45g of water and stir evenly to obtain high temperature resistant material components;

[0050] Step 2. Preparation of silicate glass components: 550g of quartz sand, 200g of alumina, 130g of soda ash, 60g of mirabilite, 150g of dolomite, 50g of feldspar, 20g of wax stone, 50g of limestone, 30g of potassium metaborate, 2g of cerium oxide, 1g of nitrate, 2g of sulfate, 20g of coloring agent, 150g of cullet, 30g of titanium oxide, 20g of antimony oxide, 10g of yttrium oxide and 200g of high temperature resistant component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com