A corrosion-resistant high-strength toughness wear-resistant bainitic steel rail and its production method

A bainite and corrosion-resistant technology, applied in other manufacturing equipment/tools, furnaces, heat treatment equipment, etc., can solve the problems of increased element segregation, decreased toughness and plasticity, high addition of alloying elements, etc., to achieve good high-strength toughness coordination, production The effect of convenient process and easy ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

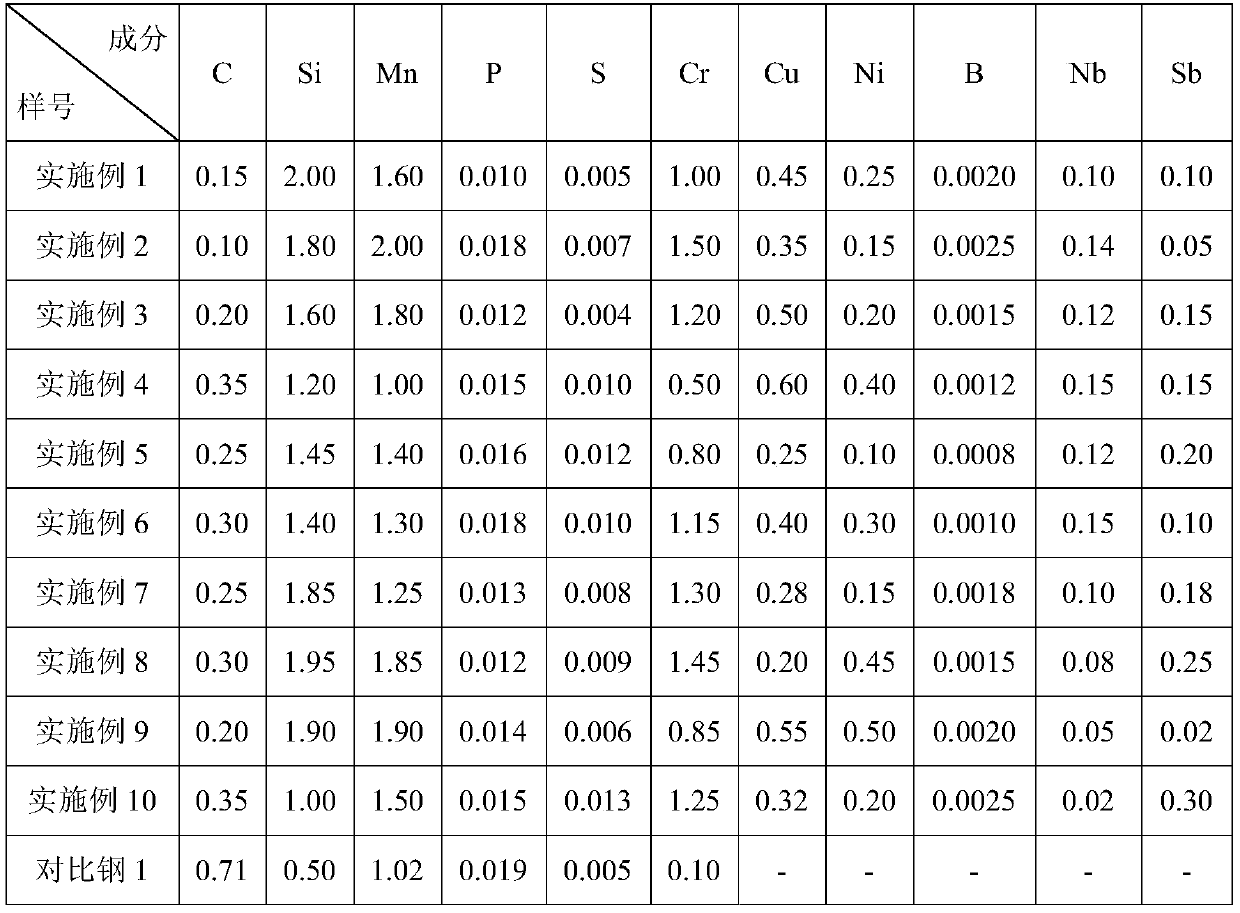

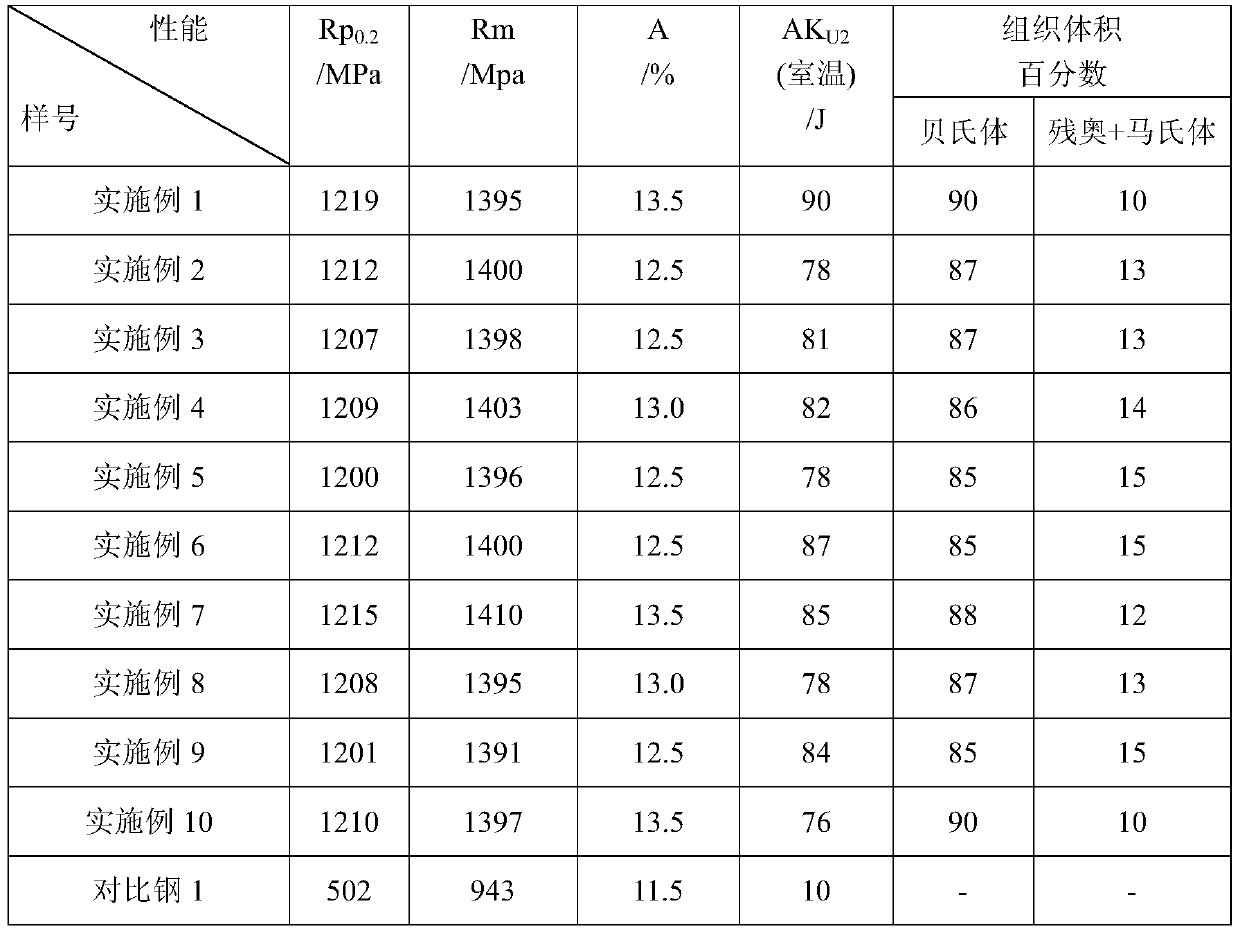

[0026] Below by embodiment the present invention will be further described.

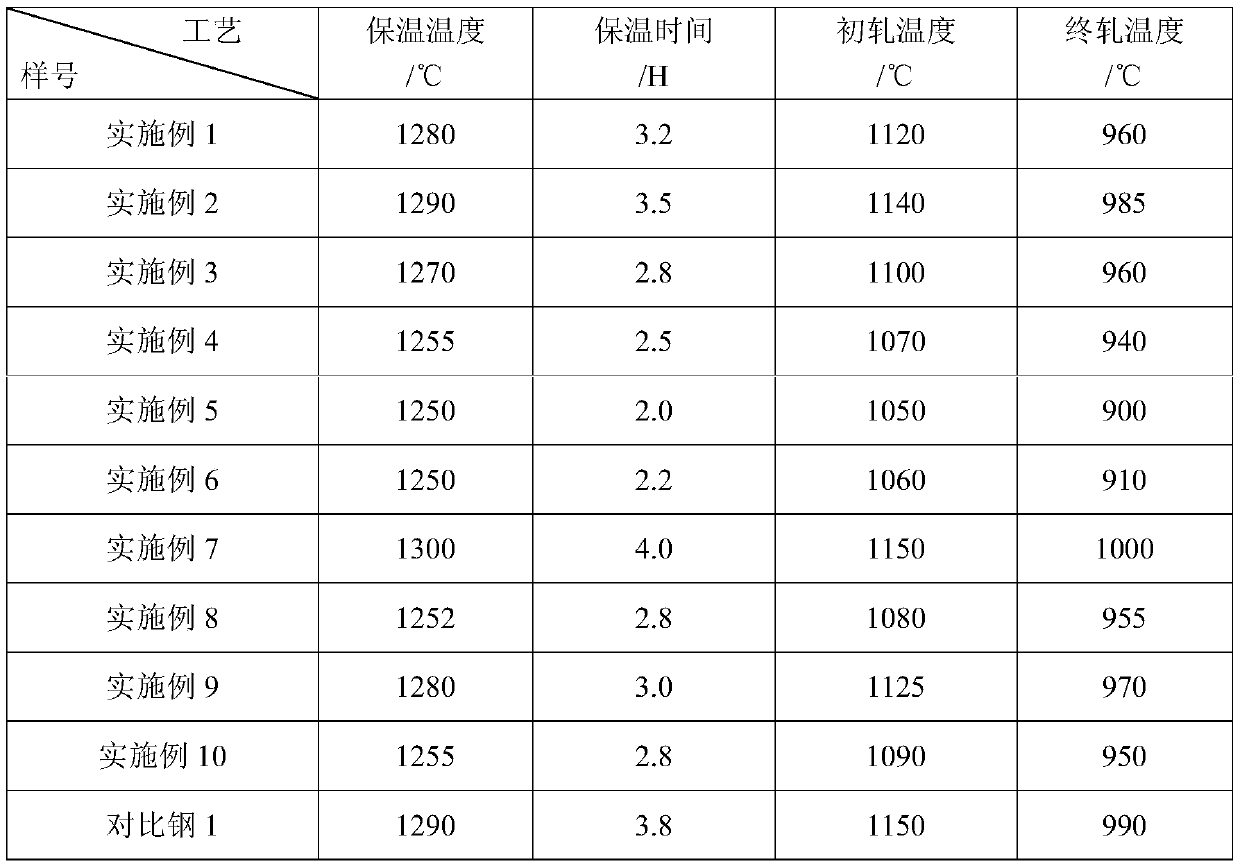

[0027] According to the component ratio of the technical solution, the embodiment of the present invention includes: smelting-refining-continuous casting-continuous casting slab heating-slab blooming-universal rolling-slow cooling; the continuous casting slab heating temperature must be controlled at 1250-1300 ℃, heat preservation for 2 to 4 hours, the temperature of blanking and initial rolling is controlled above 1100 ℃, the temperature of universal rolling is not lower than 900 ℃, and air cooling after rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com