Prefabricated lightweight high-strength bridge crash barrier

A prefabricated assembly, anti-collision guardrail technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of not conforming to the development of green buildings, increase the construction period, and low degree of assembly, achieve weight reduction, and promote lightweight. , the effect of high degree of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

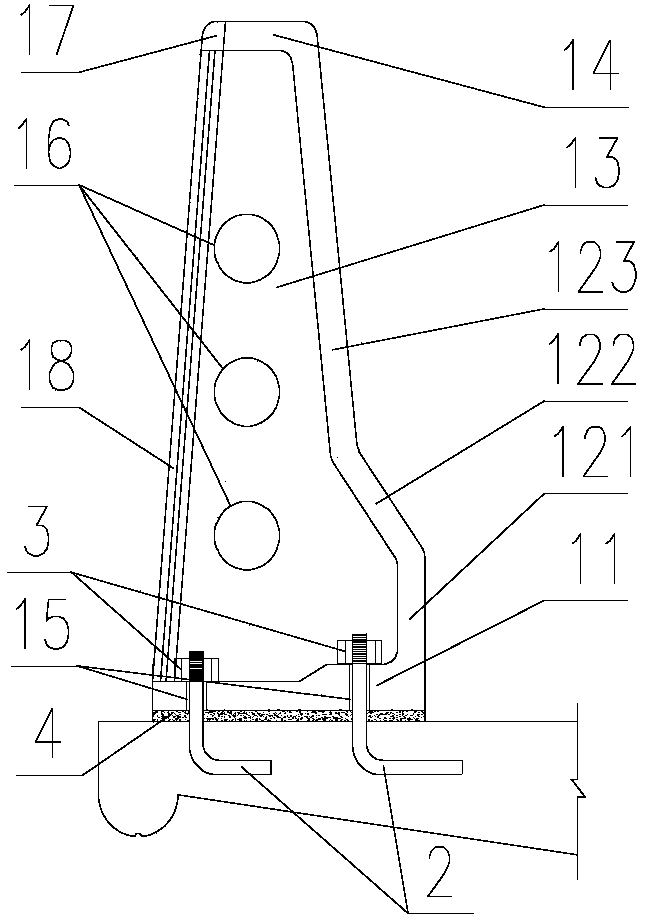

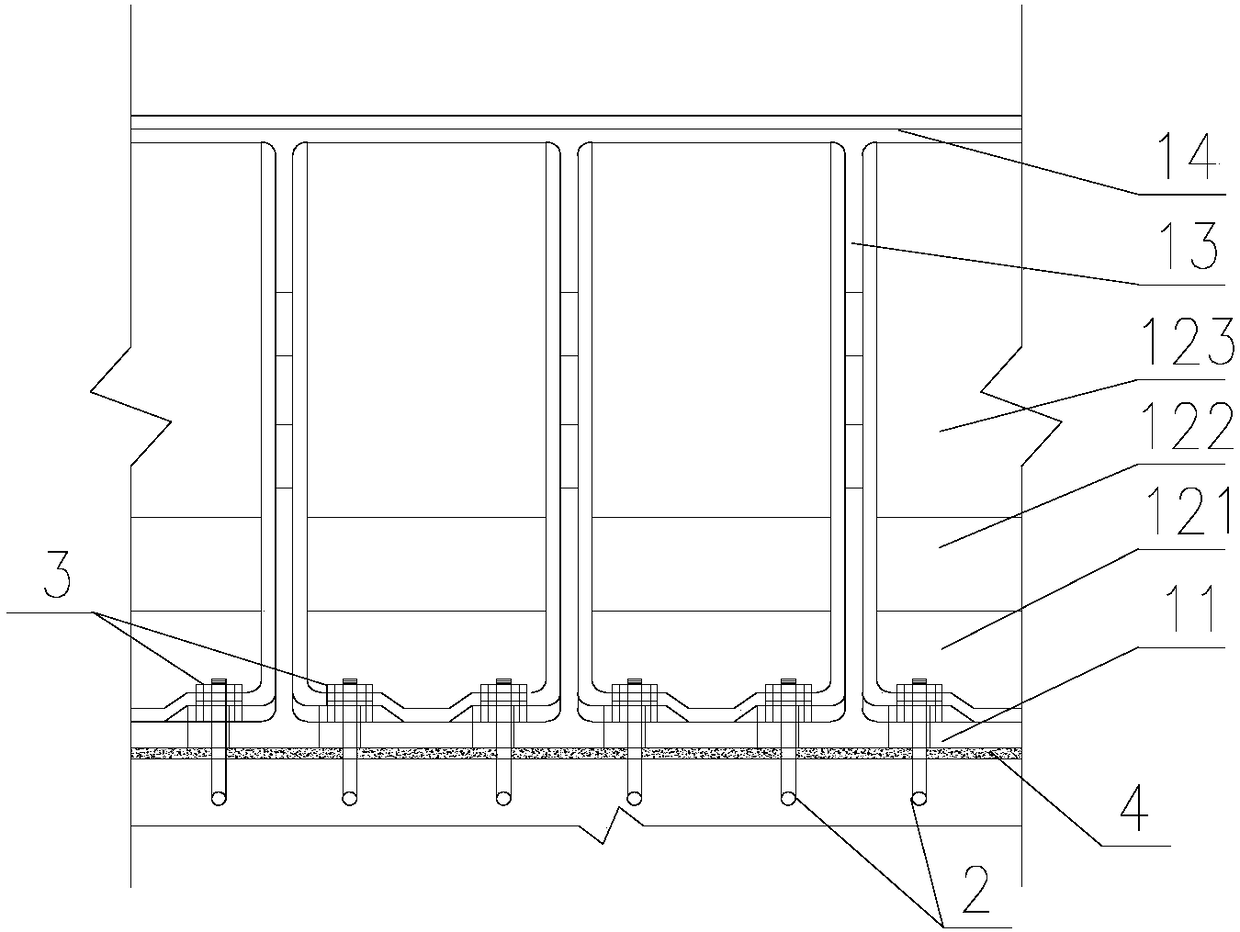

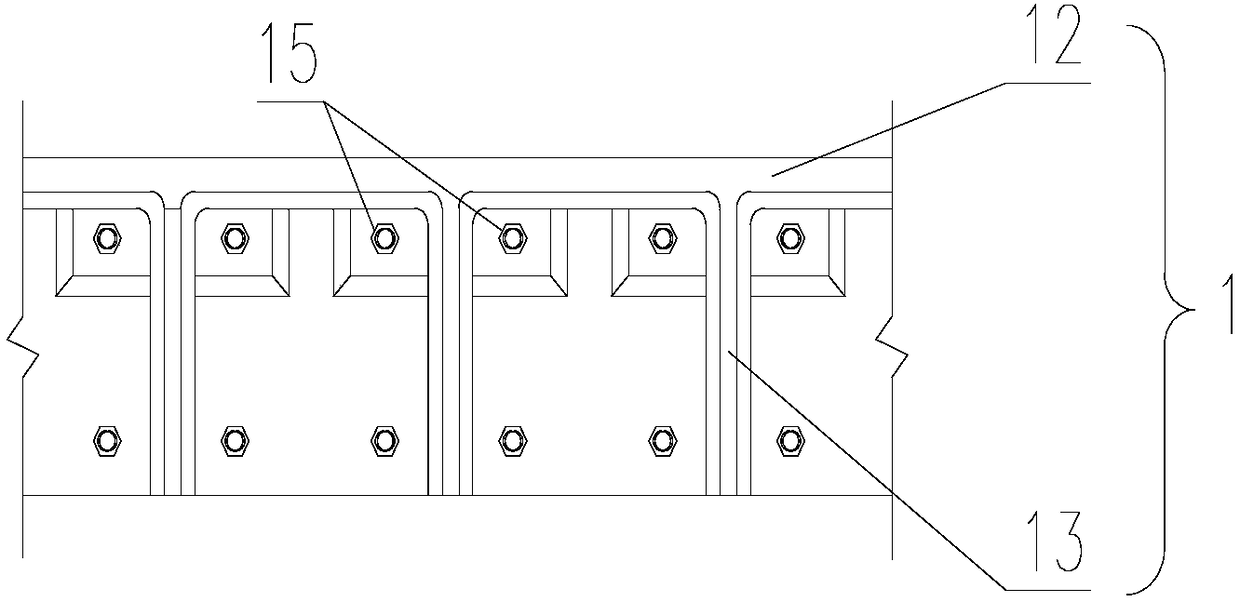

[0027] refer to Figure 1 to Figure 6 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each component of the present invention will be described in detail below.

[0028] The present invention provides a kind of prefabricated assembled light-duty high-strength bridge anti-collision guardrail, comprises the guardrail 1 that adopts ultra-high-performance concrete to prefabricate, and ultra-high-performance concrete (UHPC, Ultra-High Performance Concrete) similar material can adopt CRC, DSP , FRHPC, HPFRCC, RPC, STC, UHPFRC and other high-performance cement-based composite materials, the guardrail 1 is installed on the bridge through the embedded parts on the bridge, and the installation position of the guardrail 1 on the bridge is preferably the top of the main beam flange plate , the guardrail 1 includes a side panel 12, a bottom plate 11 and a rib 13 arranged outside the side panel 12, the spacing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com