Laser light source, light emitting device and lamp

A technology of a laser light source and a light-emitting device, applied in the field of lighting, can solve the problems of difficulty and high cost of processing glass aspherical lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

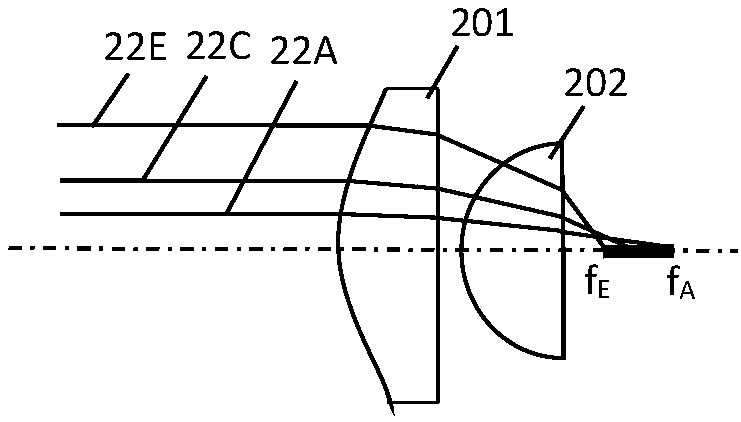

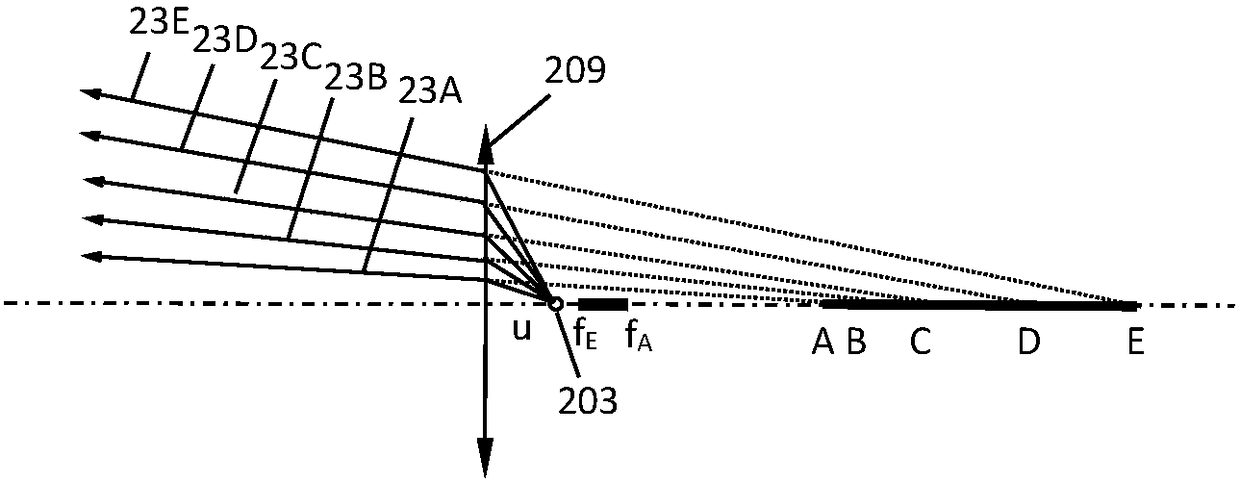

[0016] Before describing the technical solution of the present invention, some deduction of optical principles will be described first. Such as Figure 2a As shown, the spherical convex lens 201 and the spherical convex lens 202 form a convex lens group. Parallel light rays 22A, 22C, and 22E are incident from the left side of the convex lens group, wherein light 22A is close to the optical axis, light 22E is close to the edge of the effective aperture of the convex lens group, and the incident position of light 22C is between light 22A and 22E. Since both 201 and 202 are spherical convex lenses with a real focus, parallel light will form a focus on the right side of the convex lens group. Due to the reason of the spherical surface, the focal points of the incident parallel rays at various positions are not the same, which is the cause of "spherical aberration". The closer the ray is to the edge of the effective aperture, the greater the spherical aberration. Specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com