Movably clamping type liquid collecting centrifugal tube

A technology of movable clips and centrifuge tubes, which is applied in the direction of sampling devices and the preparation of test samples, etc., can solve the problems of inability to adjust the height of the liquid collection tube, unstable connection, and inability to fix the liquid collection tube, etc., and achieves ingenious connection structure design, The effect of convenient operation and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

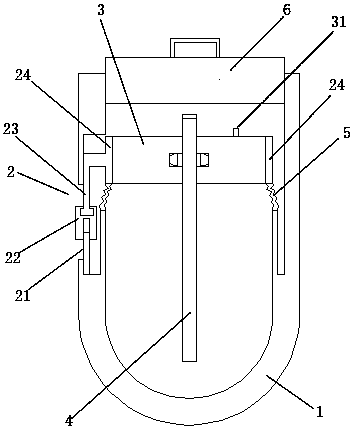

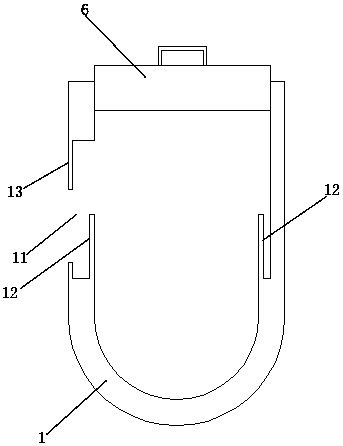

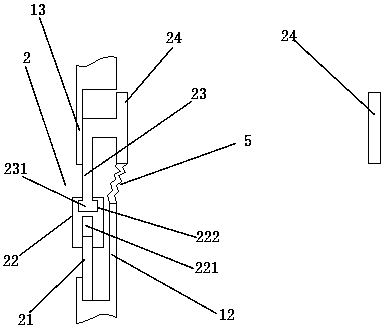

[0023] Such as figure 1 As shown, a liquid-taking centrifuge tube with movable clamping body includes a liquid storage tank 1, an upper cover body 6, a liquid-collecting tube 4, a lifting mechanism 2, an installation block 3, and a telescopic bag 5. The upper cover body 6 is installed on the upper end of the liquid storage tank 1 . Such as figure 2 As shown, the liquid storage tank 1 has a U-shaped structure, and one side of the liquid storage tank 1 is provided with a mounting groove 11 , a limiting plate 13 is provided above the mounting groove 11 , and an isolation ring 12 is provided inside the mounting groove 11 . Such as Figures 1 to 3 As shown, the lifting mechanism 2 includes a support screw 21, a moving block 22, a drive plate 23, and a connecting ring 24. The outside of the support screw 21 is provided with external threads, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com