Clamping device used in cooperation with hardness meter

A technology of clamping device and hardness tester, which is applied in the direction of measuring device, testing material hardness, strength characteristics, etc., can solve the problems of part shape and size limitation, unable to meet the measurement requirements of special parts of parts, etc., to prevent movement and rolling, widen The effect of using range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

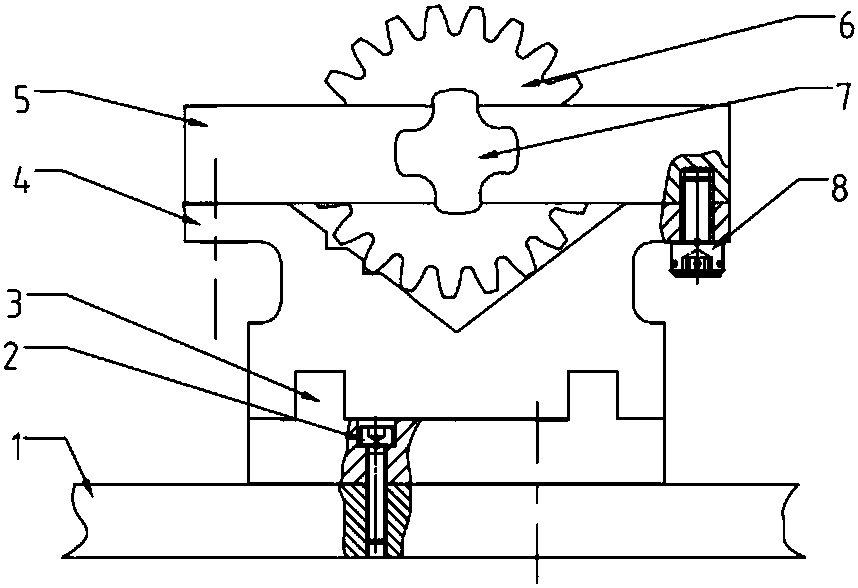

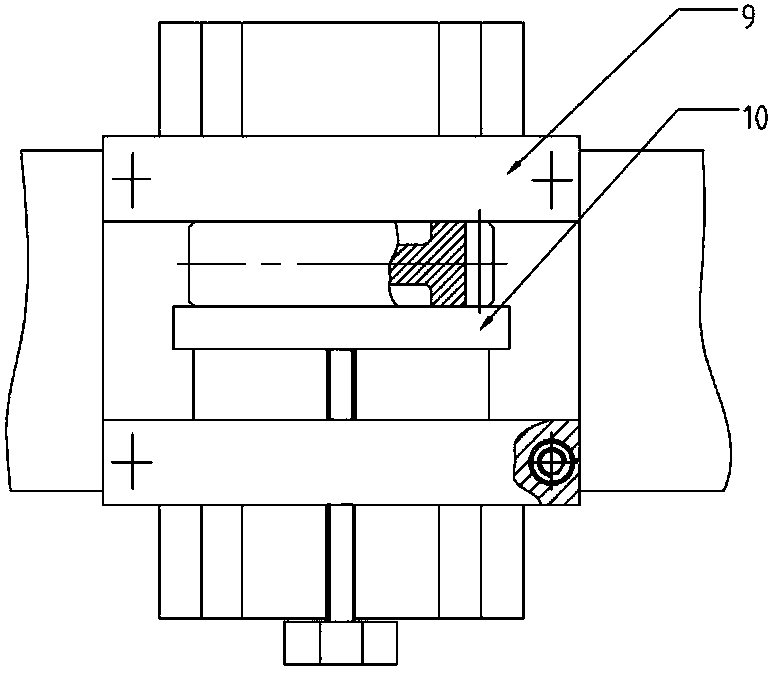

[0025] The invention is a clamping device designed to solve the clamping problem when measuring the hardness of the long-axis parts and the tooth surface of gear parts. The clamping device is arranged in an upper, middle and lower structure, and the entire clamping device is fastened on the hardness tester base with connecting bolts through the existing threaded holes on the hardness tester base.

[0026] Such as figure 1 As shown, the clamping device includes a clamping base 3 and a clamping block 4 . The clamping base 3 is fixed on the hardness tester base 1 through the connecting bolts 2, so that the clamping device and the hardness tester are integrated to ensure the stability of the entire clamping device. The upper surface of the clamping base 3 is provided with two parallel guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com