A Method for Accurately Determining the Softening Point of Rosin Using Temperature Programmed Headspace Gas Chromatography

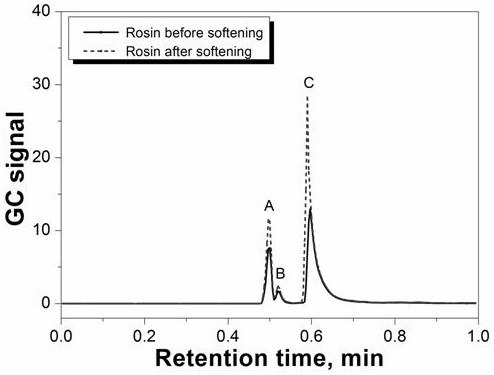

A headspace gas chromatography and temperature-programmed technology is applied in the field of detection of rosin properties, which can solve the problems of cumbersome and time-consuming measurement steps, and achieve the effects of simple operation, overcoming the complexity of instruments, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

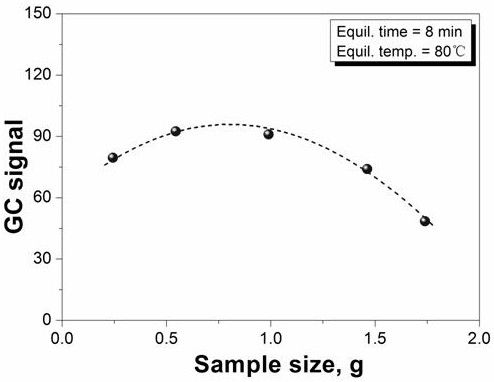

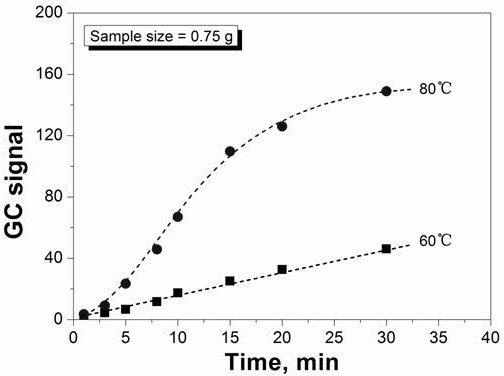

[0026] Put 0.75g of block rosin in a headspace bottle, seal it and place the headspace bottle in a headspace sampler, equilibrate at 60°C for 8min, and then detect the signal value of a volatile substance. Then every 3°C rise, equilibrate for 8 minutes, record the signal value of the corresponding volatile substances in the front of the chromatogram, and measure about 8 times in total. Finally, draw a graph of the relationship between the signal value of the volatile substance and the corresponding temperature; determine the softening point of the rosin sample according to the turning point of the graph.

[0027] The conditions of the headspace sampler were as follows: the vibration condition was set to strong oscillation, the pressurization time of the headspace bottle was 15 s, the filling time of the quantitative loop was 10 s, and the transfer time to the GC was 20 s. Gas chromatography operating conditions: hydrogen flame ion detector (FID), carrier gas is nitrogen, combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com