Method for calculating temperature field distribution of sleeve with inserting and connecting structure

A technology of plug-in structure and distribution method, which is applied in the field of electric power, can solve the problem of incomplete ohmic heating of conductive rods, achieve wide practicability and economy, and reduce design cycle and design costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

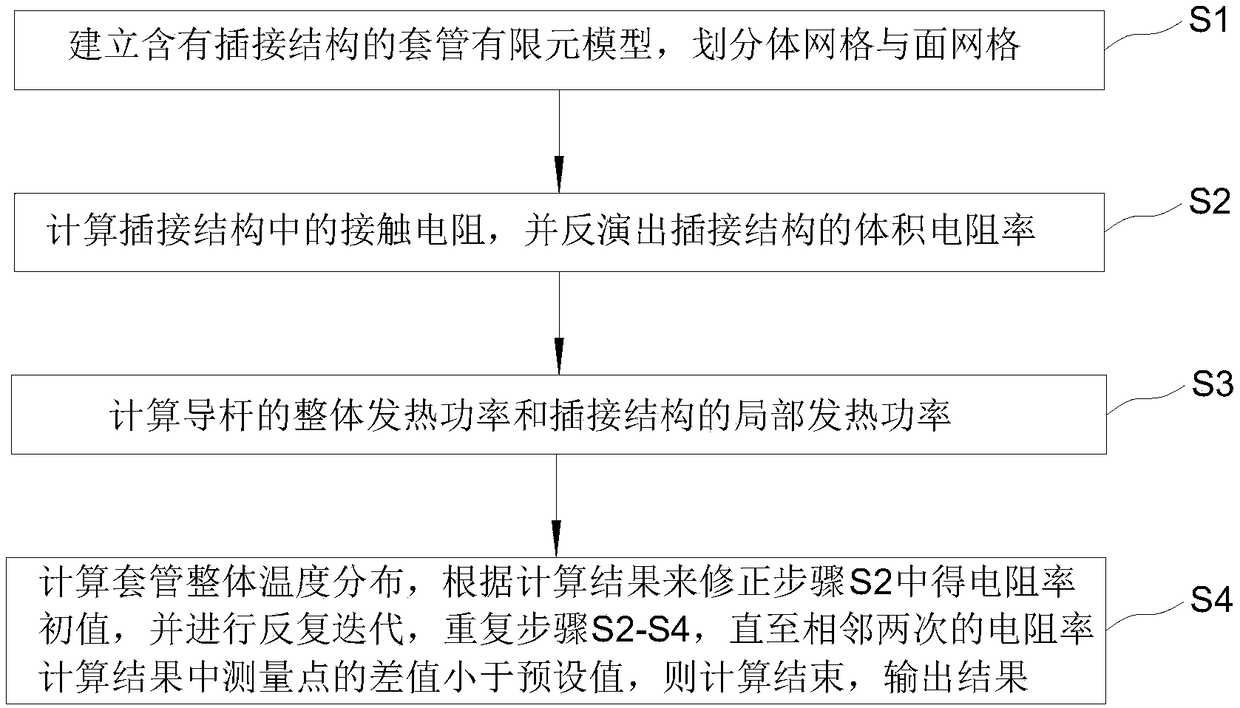

[0027] refer to figure 1 As shown, the method for calculating the temperature field distribution of the casing with a plug-in structure provided in this embodiment includes the following steps:

[0028] S1. Establish the casing finite element model with plug-in structure, and divide the volume mesh and surface mesh

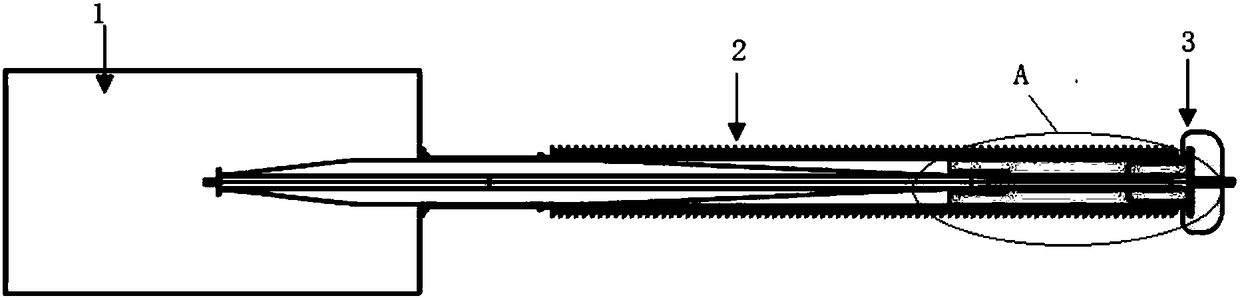

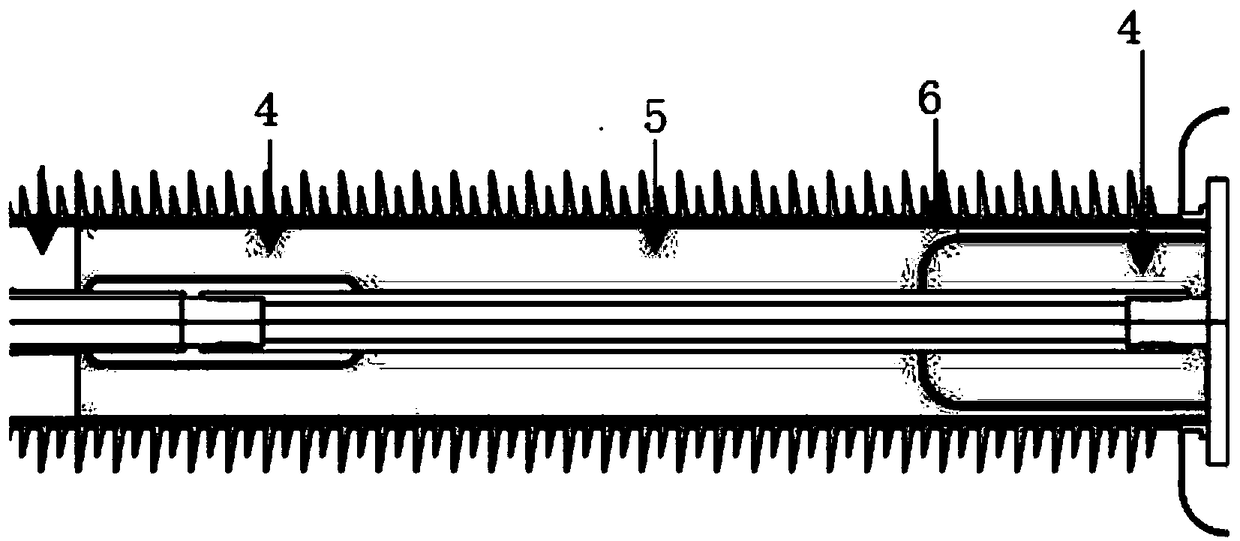

[0029] Use 3D modeling software to build the casing model with plug-in structure, such as Figure 2-3 As shown, the model includes but is not limited to guide rod, epoxy core, SF 6 Necessary structures such as gas 5, flange structure and sheath, transformer oil 1, sheath 2, end fittings 3, internal shielding 6, connection components 4, etc., are imported into the casing model with APDL (ANSYS Parametric Design Language), and can be used for Calculate the finite element analysis model, and establish a grid division program through the APDL language to divide the volume grid in the calculation domain and the surface grid that needs to be coupled in the heat distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com