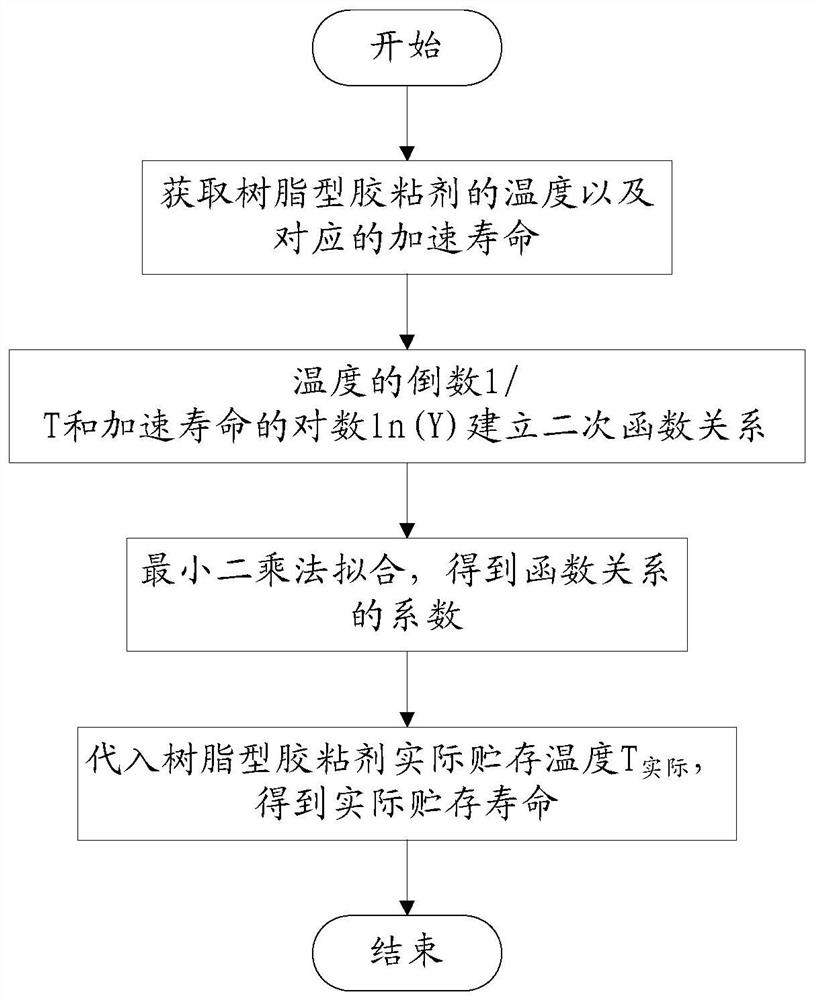

Method, device and electronic equipment for determining storage life of resin adhesive

A technology of storage life and determination method, applied in the field of resin adhesive storage life and accelerated test, can solve the problem of not being able to accurately obtain the storage life of epoxy resin adhesive, and achieve the relationship between full consideration, high convergence accuracy, and accurate accelerated life estimation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

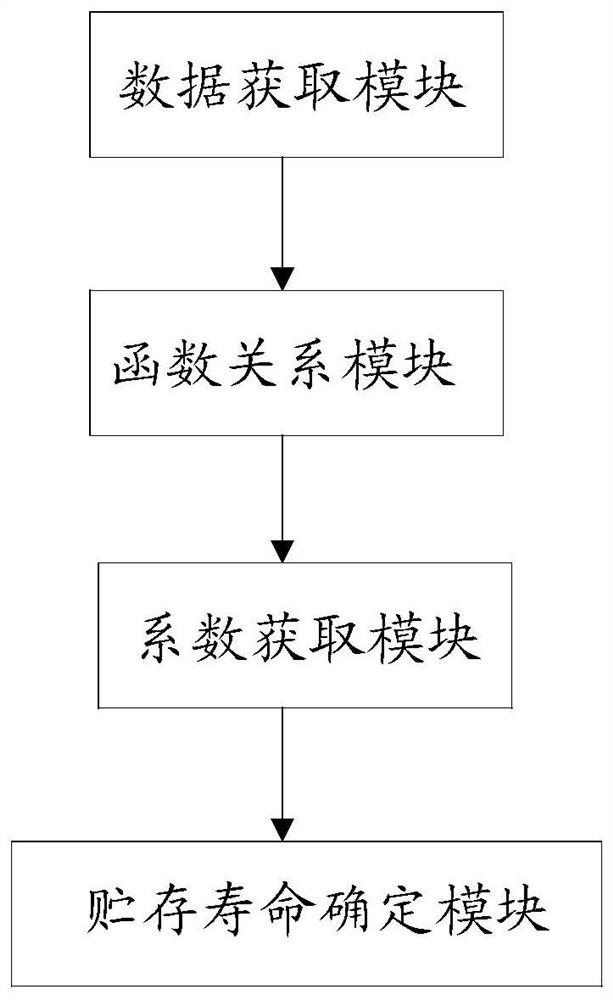

Method used

Image

Examples

Embodiment 1

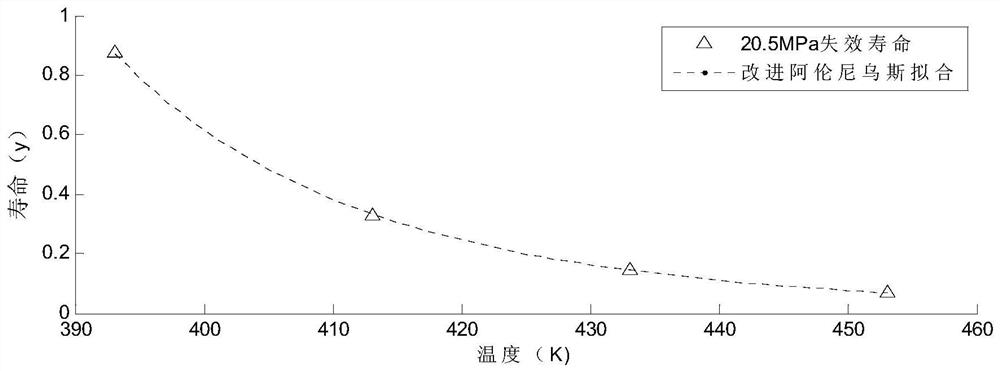

[0082] This embodiment adopts the calculation method of the epoxy resin adhesive storage life of the present invention, the failure condition of the epoxy resin is that the tensile shear strength P is less than 20.5Mpa condition, according to the fitting adhesive shear strength change rate of the model, obtain four The failure time under the accelerated test temperature is: 393.15K (120°C) failure life is 318.77 days, 413.15K (140°C) is 120.15 days, 433.15K (160°C) is 52.62 days, 453.15K (180°C) failure life is 24.76 days.

[0083] According to the relationship between epoxy resin failure life and temperature The results obtained by fitting the least squares method are as follows: image 3 as shown in image 3 Shown is a schematic diagram of the agreement between the storage life obtained by the method of the present invention and the actual measured value in embodiment 1; wherein a=1.251×10 6 , b=1626.395, c=-12.369, the goodness of fit is 99.996%. At the same time, it can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com