A device and method for predicting reverse osmosis membrane fouling

A reverse osmosis membrane and time technology, applied in the field of reverse osmosis systems, can solve the problems of water quality decline, restricting the stable operation of reverse osmosis process, membrane flux decline, etc., achieving high accuracy, good prediction effect, and excellent fitting. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

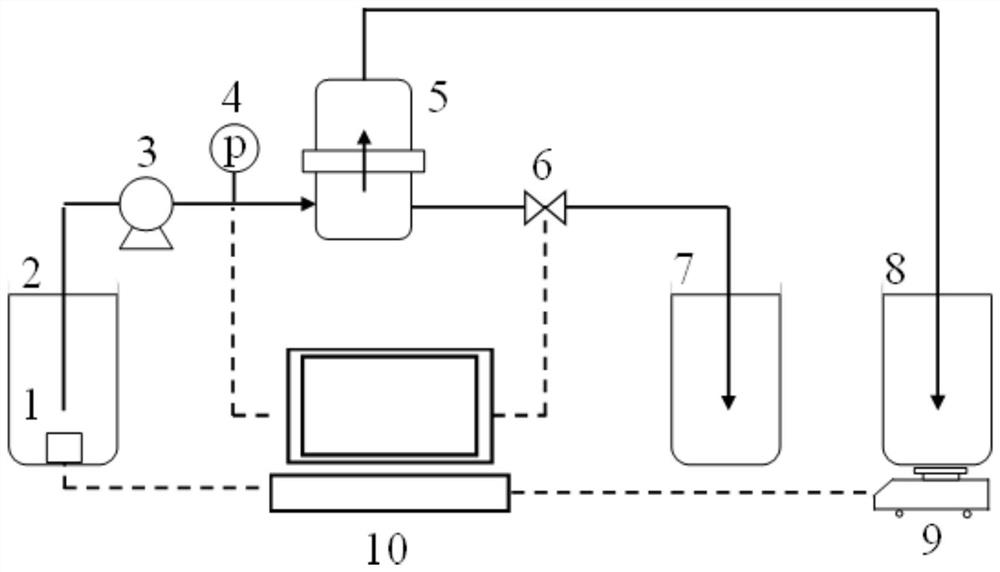

[0046] A device that predicts reverse osmosis membrane blocked, such as figure 1 Indicated.

[0047] The device includes a reverse osmosis flat film unit 5 and an inlet tank 2, a water tank 7, a water tube, a water pipe, and a water pipe and a reverse osmotic flat film unit 5, respectively, and is mounted in the inner side of the water tank 2 The temperature monitor 1 of the inlet temperature is monitored in real time. The water pump 3 and pressure Table 4 are mounted on the water pipe. The water supply valve is mounted on the concentrated water pipe 6, and the water tank 8 is provided with electronic balance for real-time recording quality. 9; the apparatus further includes a computer 10, and the computer 10 is connected to the temperature monitor 1, the pressure table 4, the concentrated water valve 6, and the electronic balance 9.

[0048] When the test is started, the test water is placed in the inlet tank 2, and the temperature of the water is monitored in real time with the ...

Embodiment 2

[0073] A method of predicting the blizing of reverse osmosis membrane, including the following steps:

[0074] S1: Control the water flux j after the correction of the reverse osmosis membrane is unchanged, determine the operating pressure ΔP of water samples in the initial time. 0 , And operating pressure ΔP at T, calculate the standardization pressure of T

[0075] S2: Calculate standardization pressure Time change rate at different times;

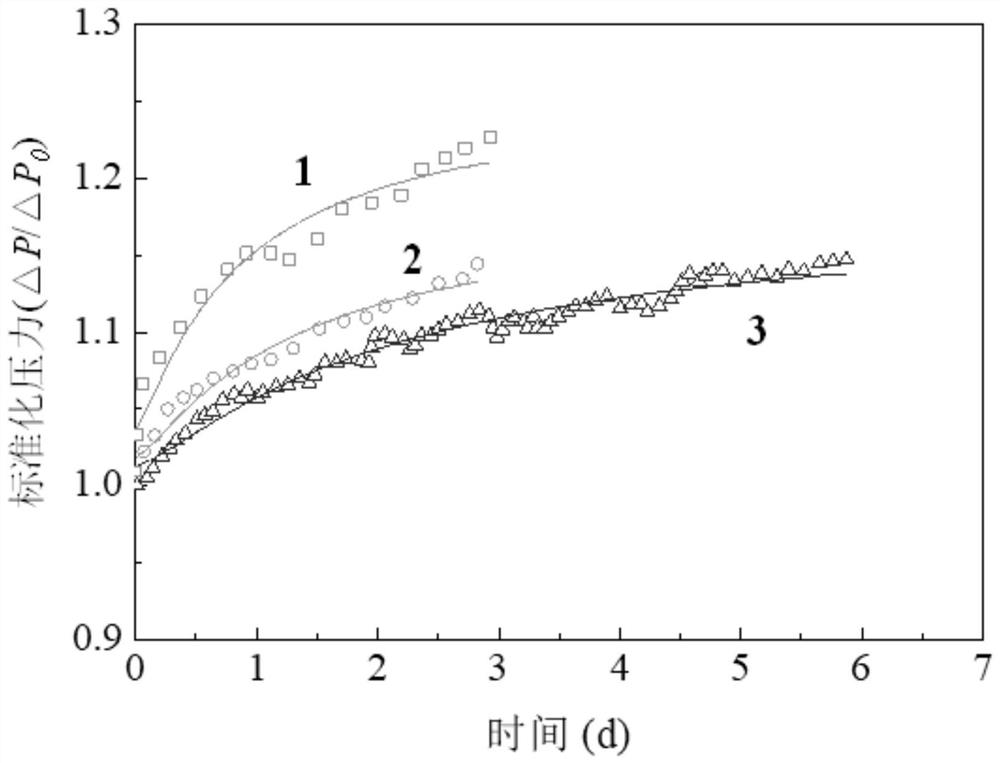

[0076] S3: Standardization pressure to Time Fitting with film blocked models, the specific process is:

[0077] If standardized pressure When the time change rate increases with the filter time T, the following model is used, and its expression is as follows:

[0078]

[0079] Where T is filtered time; ΔP is the operation pressure of T, ΔP 0 The operating pressure of the initial moment, For standardization pressure; J is a quantity of quantities; Δπ N It is an osmotic pressure whose initial operating pressure is standardized; α is the...

Embodiment 3

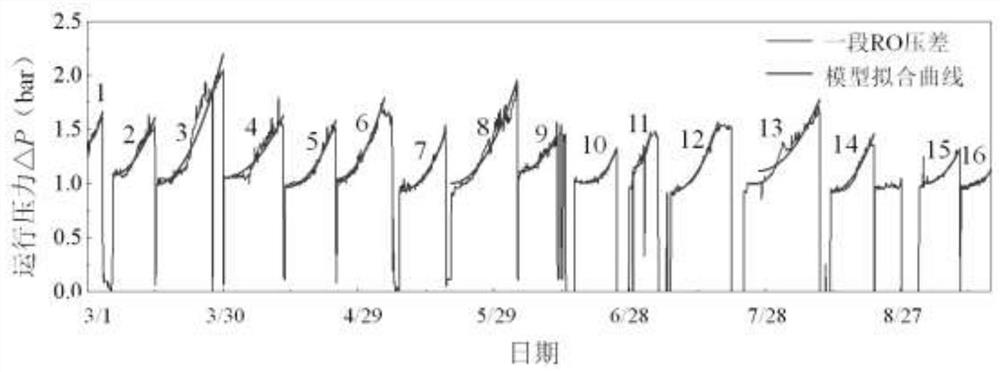

[0100] The model one is used for fitting the laboratory and the actual operating RO system standardized pressure - time change data, the fit results figure 2 As shown, the model is used to simulate the operation pressure of the RO system of a actual renewable water plant. The water plant uses a microfiltration-reverse osmosis (MF-RO) double membrane process to purify the secondary water of the urban sewage treatment plant to produce industrial regeneration water and supplement drinking water sources, according to the formula 1-3, calculate the system The water flux in which the osmotic RO film correction is 17LMH, and the flux j in the computer is provided in the computer 17LMH.

[0101] The fitting process is: Enter standardized pressure to ORIGIN 2018 (ΔP / ΔP) 0 ) - Time data and expression of model one. Origin 2018 is fitted to the pressure-time curve with the least squares method. After multiple iterations, the fitting curve and the model parameter value are obtained, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com