Device and method for predicting sewage blockage of reverse osmosis membrane

A technology of reverse osmosis membrane and time, which is applied in the field of reverse osmosis system, can solve the problems such as the decline of membrane flux, the decline of produced water quality, and the limitation of stable operation of reverse osmosis process, achieving high accuracy, good prediction effect and excellent fitting high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

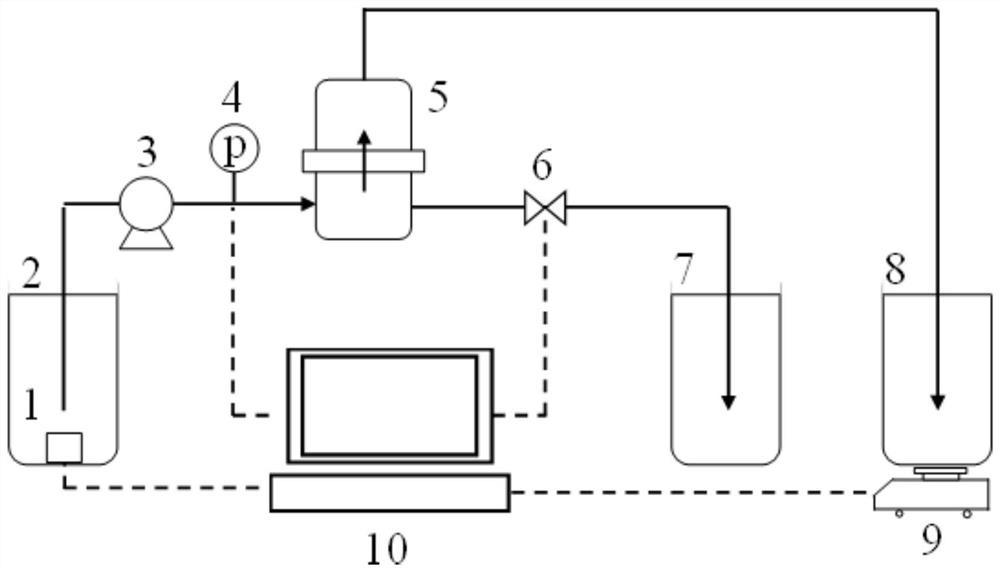

[0046] A device for predicting reverse osmosis membrane fouling, such as figure 1 shown.

[0047] The device includes a reverse osmosis flat membrane unit 5 and a water inlet tank 2, a concentrated water tank 7 and a water product tank 8 connected to the reverse osmosis flat membrane unit 5 through a water inlet pipe, a concentrated water pipe and a water production pipe respectively; A temperature monitor 1 for real-time monitoring of the inlet water temperature, an inlet pump 3 and a pressure gauge 4 are installed on the inlet pipe, a concentrated water valve 6 is installed on the concentrated water pipe, and an electronic balance for real-time recording of the product water quality is installed at the bottom of the product water tank 8 9; The device also includes a computer 10, which is connected to the temperature monitor 1, the pressure gauge 4, the concentrated water valve 6 and the electronic balance 9 respectively.

[0048] When starting the test, the test water sampl...

Embodiment 2

[0073] A method for predicting reverse osmosis membrane fouling, comprising the steps of:

[0074] S1: Control the corrected product water flux J of the reverse osmosis membrane to remain unchanged, and measure the operating pressure ΔP of the water sample at the initial moment 0 , and the operating pressure ΔP at time t, calculate the normalized pressure at time t

[0075] S2: Calculation of normalized pressure Time rate of change at different moments;

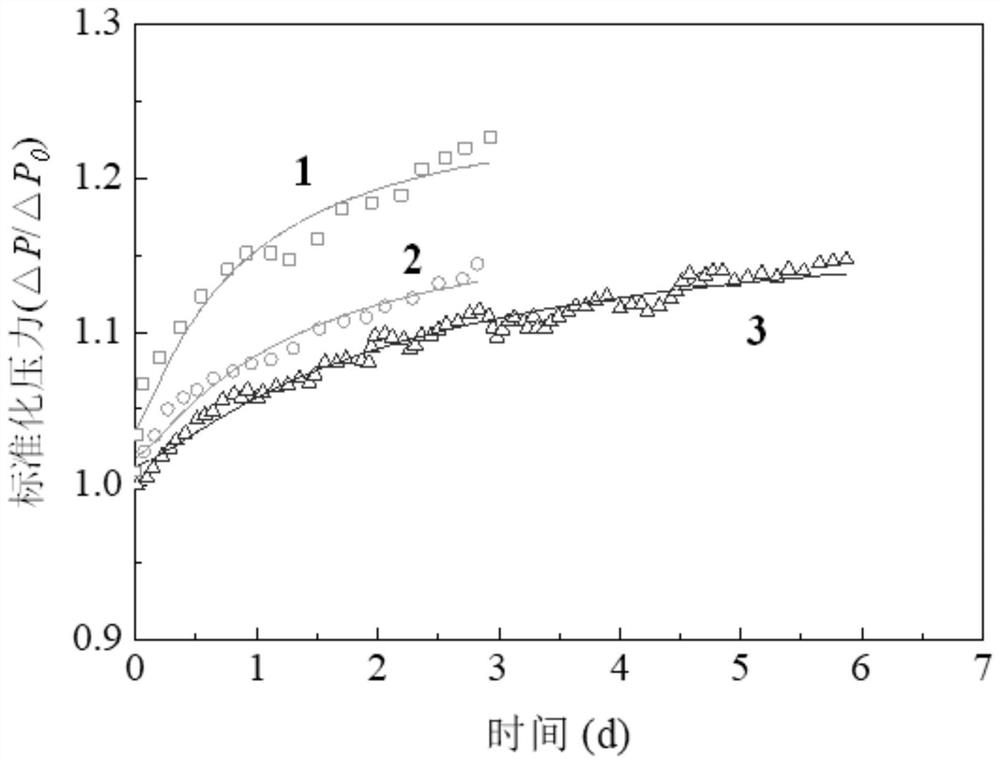

[0076] S3: The normalized pressure at time t The membrane fouling model is used for fitting, and the specific process is as follows:

[0077] If normalized pressure When the time rate of change of increases with the increase of filtering time t, the following model 1 is adopted, and its expression is as follows:

[0078]

[0079] Among them, t is the filtration time; ΔP is the operating pressure at time t, ΔP 0 is the operating pressure at the initial moment, is the normalized pressure; j is the dimensionless ...

Embodiment 3

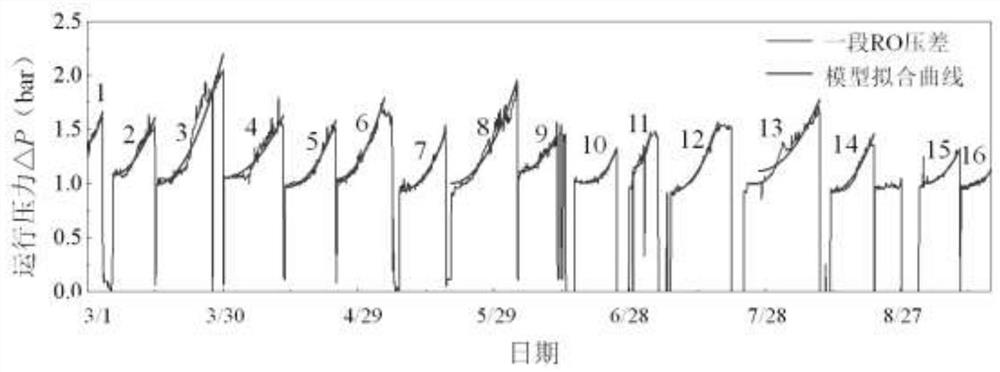

[0100] Model 1 is used to fit the standardized pressure-time change data of the laboratory and the actual operating RO system. The fitting results are as follows: figure 2 As shown, Model 1 is used to simulate the operating pressure change of the RO system of an actual reclaimed water plant. The water plant uses the microfiltration-reverse osmosis (MF-RO) double-membrane process to purify the secondary effluent of the urban sewage treatment plant to produce industrial reclaimed water and supplement drinking water sources. According to formula 1-3, the reaction in the system is calculated The corrected permeate flux of the RO membrane is 17LMH, and the flux J of the RO membrane is set to 17LMH in the computer.

[0101] The fitting process is: input the normalized pressure (ΔP / ΔP 0 )-time data and the expression for model one. Origin 2018 uses the least square method to fit the pressure-time curve. After multiple iterations, the fitted curve and model parameter values are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com