A processing method for high temperature and high cycle fatigue performance data of materials

A high-cycle fatigue and processing method technology, applied in electrical digital data processing, special data processing applications, analysis of materials, etc., can solve the problem of limited number of temperature points, high test time and economic cost, and difficulty in ensuring sufficient samples. and other problems to achieve accurate and efficient prediction, improve the goodness of fit, and reduce the number of equations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

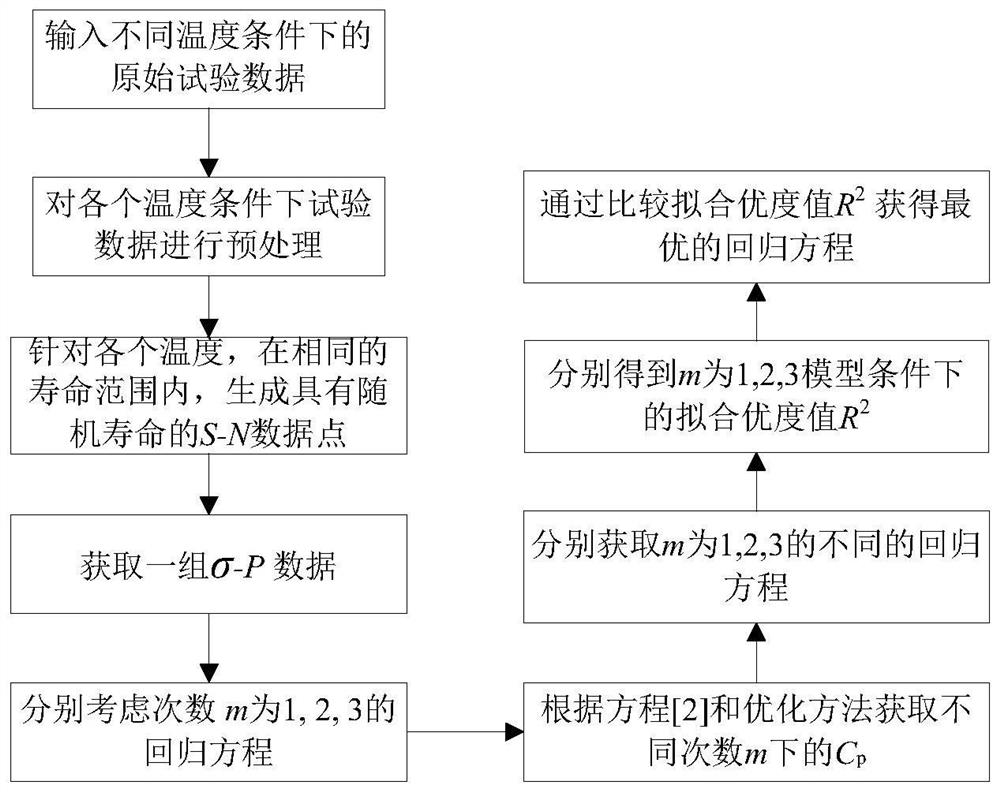

[0030] See attached figure 1 As shown in the flow chart, the steps of the processing method for the high-temperature and high-cycle fatigue performance data of this material are as follows:

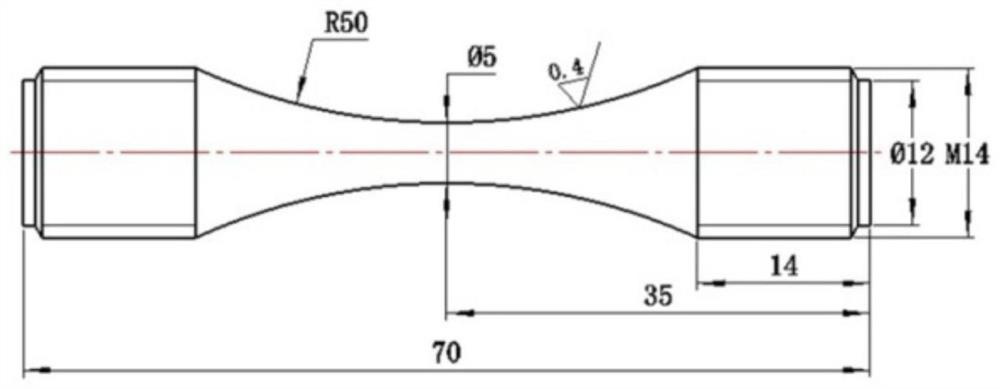

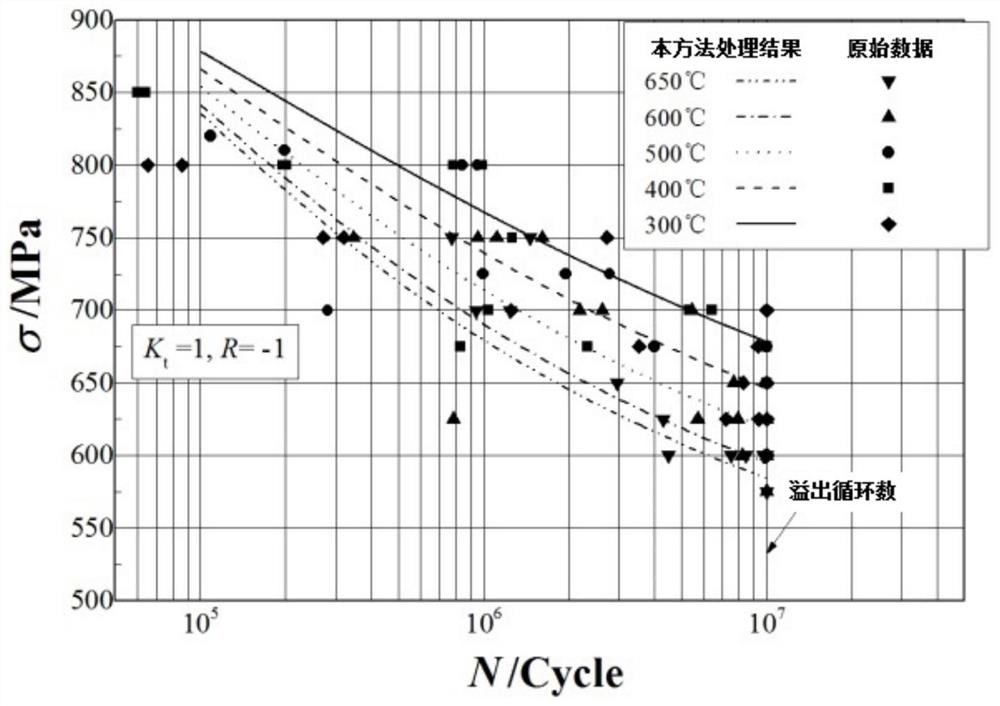

[0031] Step 1. For the axial high cycle fatigue specimen of the nickel-based superalloy with the brand name GH4149, the shape and size of the specimen are shown in figure 2 , and the stress ratio is -1 to obtain high cycle fatigue stress-life data under five temperature conditions of 300°C, 400°C, 500°C, 600°C and 650°C respectively, and import the original high temperature fatigue data under different temperature conditions into the actual In the three-parameter power exponent fatigue stress-life equation, the regression parameters of the equation are obtained by regression calculation of the least square method;

[0032] Step 2. First consider the condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com