Environment-friendly enameled wire film-stripping device with double-gear combination structure

A combined structure and environment-friendly technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of incomplete paint removal, poor environmental protection, physical injury, etc., to avoid incomplete scraping, structure Simple, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

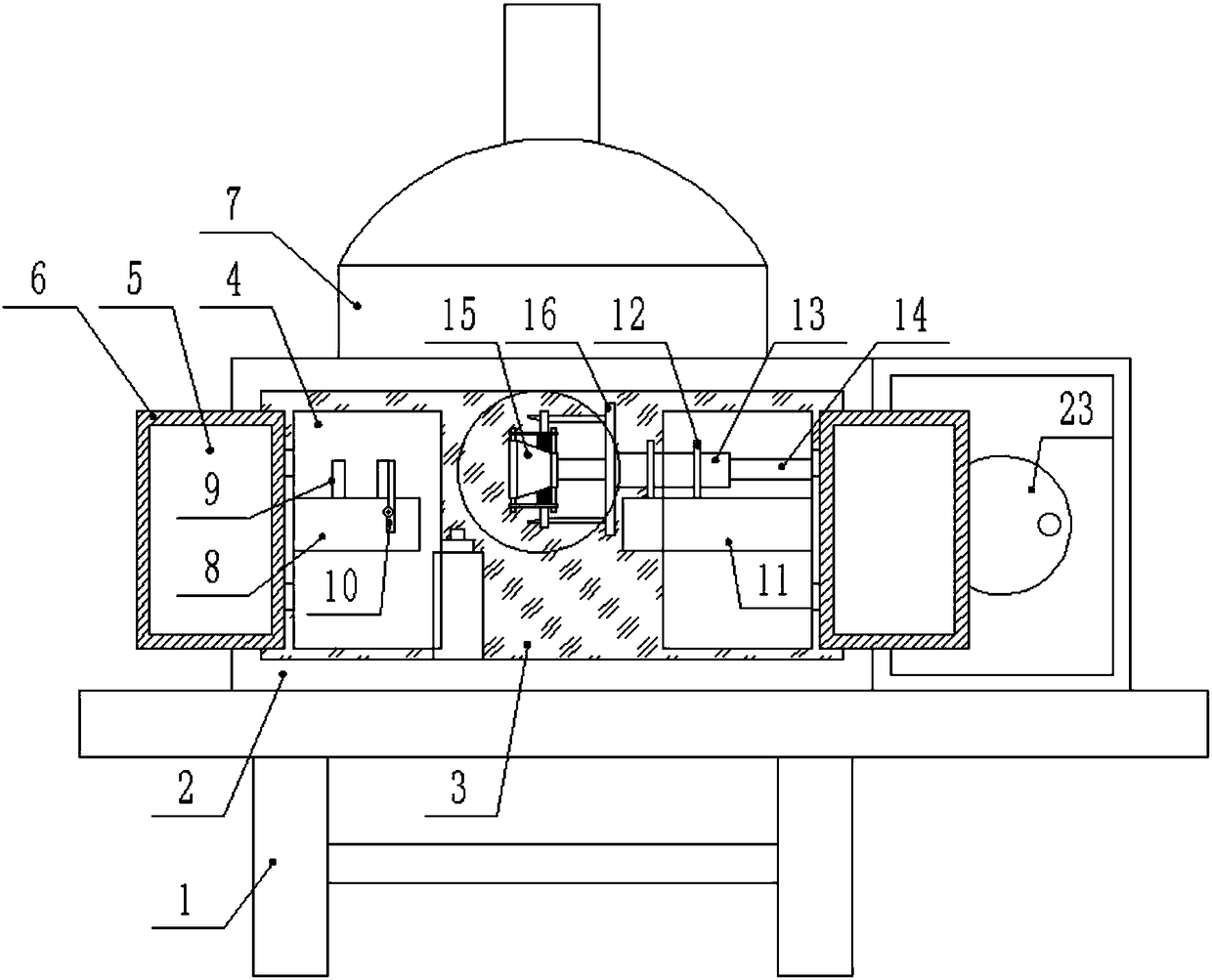

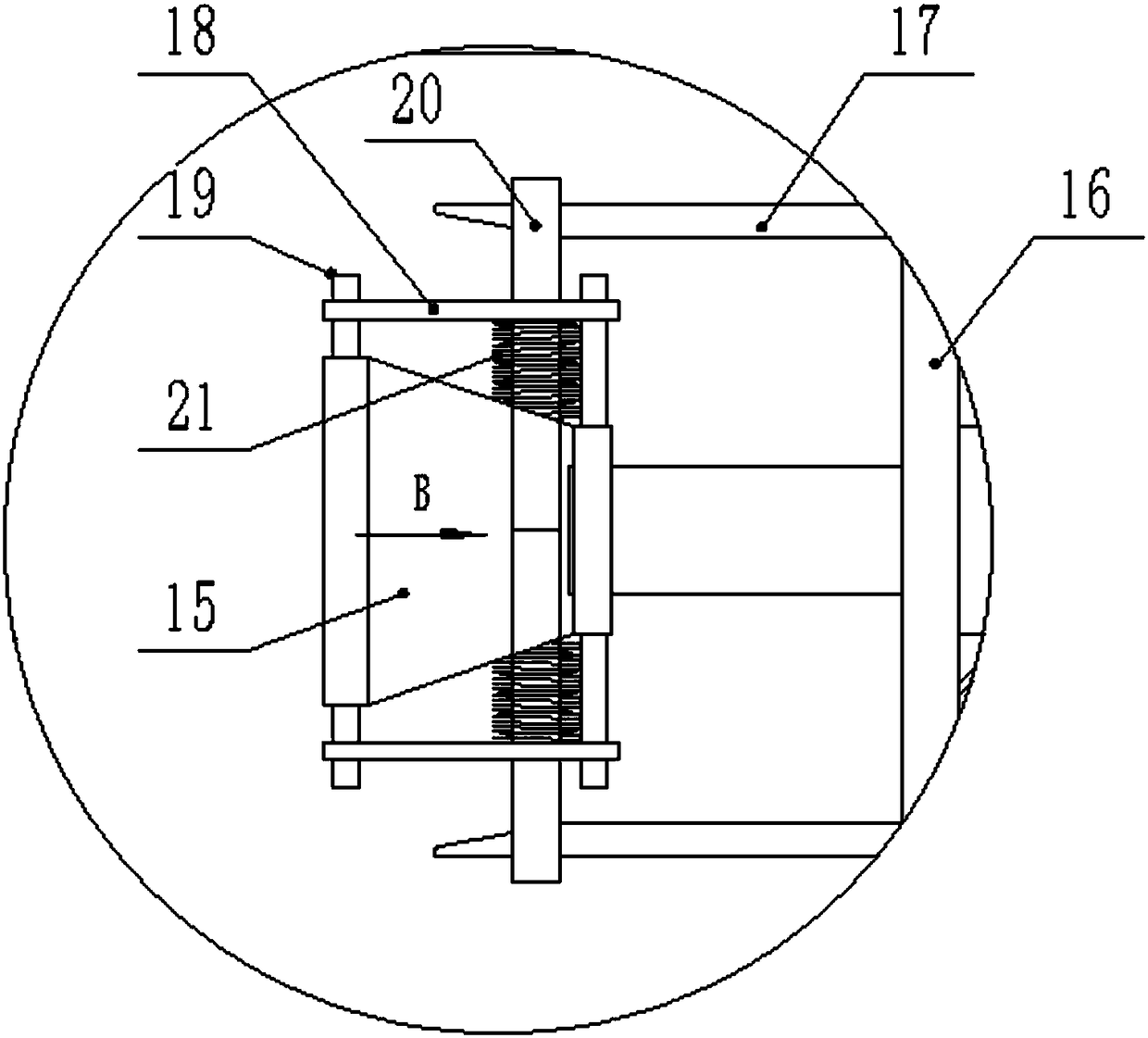

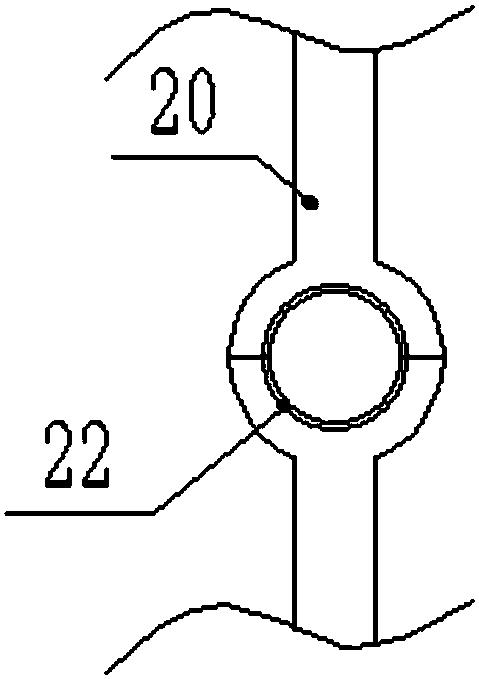

[0022] see Figure 1-4 , an environment-friendly enameled wire depainting device with a double gear combination structure, comprising a device body, the device body is provided with a support frame 1, an operating room 2 is provided above the support frame 1, and the operating room 2 and the support frame 1 The protective glass 3 is set on the front of the operating room 2, and the protective glass 3 and the operating room 2 are fixedly connected by fastening screws. The top of the operating room 2 is provided with a guide The smoke pipe 7, the smoke guide pipe 7 and the outer wall of the operating room 2 are fixed by screws, the smoke guide tube 7 communicates with the inside of the operating room 2, and the protective glass 3 is provided with two operating ports 4, so The operation port 4 communicates with the inside of the operating room 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com