Cable semiconduction fracture treatment method

A processing method, semi-conductive technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of time-consuming, repeated grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Such as figure 1 Shown, be a kind of cable semiconducting fracture treatment method of the present invention, at first semiconducting shielding layer is carried out preliminary scraping; Then wrap 1-2 layers of semiconducting tapes evenly on insulating layer and semiconducting shielding layer, use again The heating belt heats and vulcanizes the semi-conductive belt.

Embodiment 2

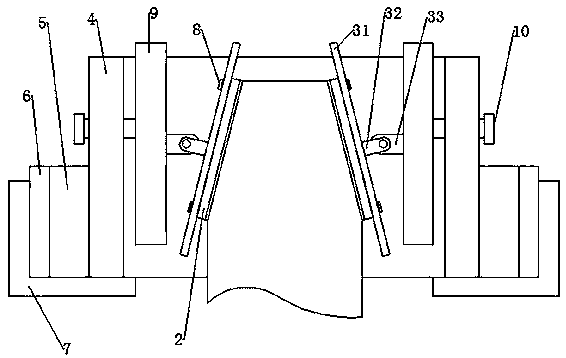

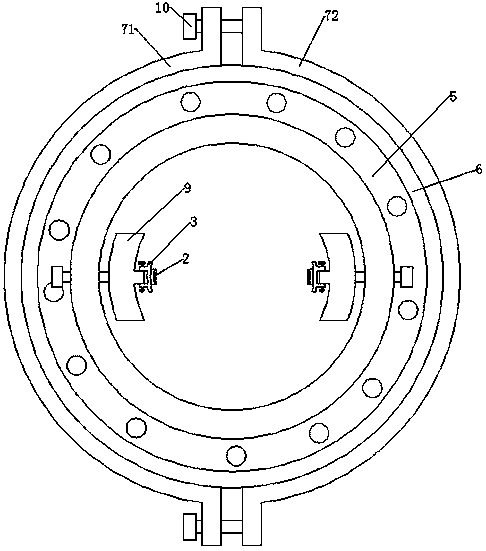

[0020] The invention uses a scraping device to scrape off the semiconductive shielding layer, and then evenly wraps 1-2 layers of semiconductive tape on the insulating layer and the semiconductive shielding layer. Such as Figure 1-2 As shown, the scraping device of the present invention includes a scraping blade 2, an angle adjustment bracket 3, a rotating block 4, a bearing 5, a transition block 6 and a base 7; the scraping blade 2 is installed on the angle adjustment bracket; the The angle adjustment bracket is installed inside the rotating block 4 ; the rotating block 4 is installed inside the transition block 6 through the bearing 5 ; the transition block 6 is arranged in the base 7 .

[0021] The angle adjustment bracket of the present invention includes a movable bracket body 31, a shaft seat one 32 with a shaft hole arranged on the rear side of the movable bracket body 31, and a shaft seat two 33 with a shaft hole arranged on the inside of the rotating block; The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com