Remote maintenance system of distribution automation terminal

A technology for distribution automation and maintenance systems, applied in the direction of electrical components, circuit devices, etc., can solve the problems of distribution automation terminal operation impact, inability to meet large-scale maintenance operations, and less useful maintenance work, so as to meet large-scale maintenance operations , improve troubleshooting efficiency, and achieve the effect of fault pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

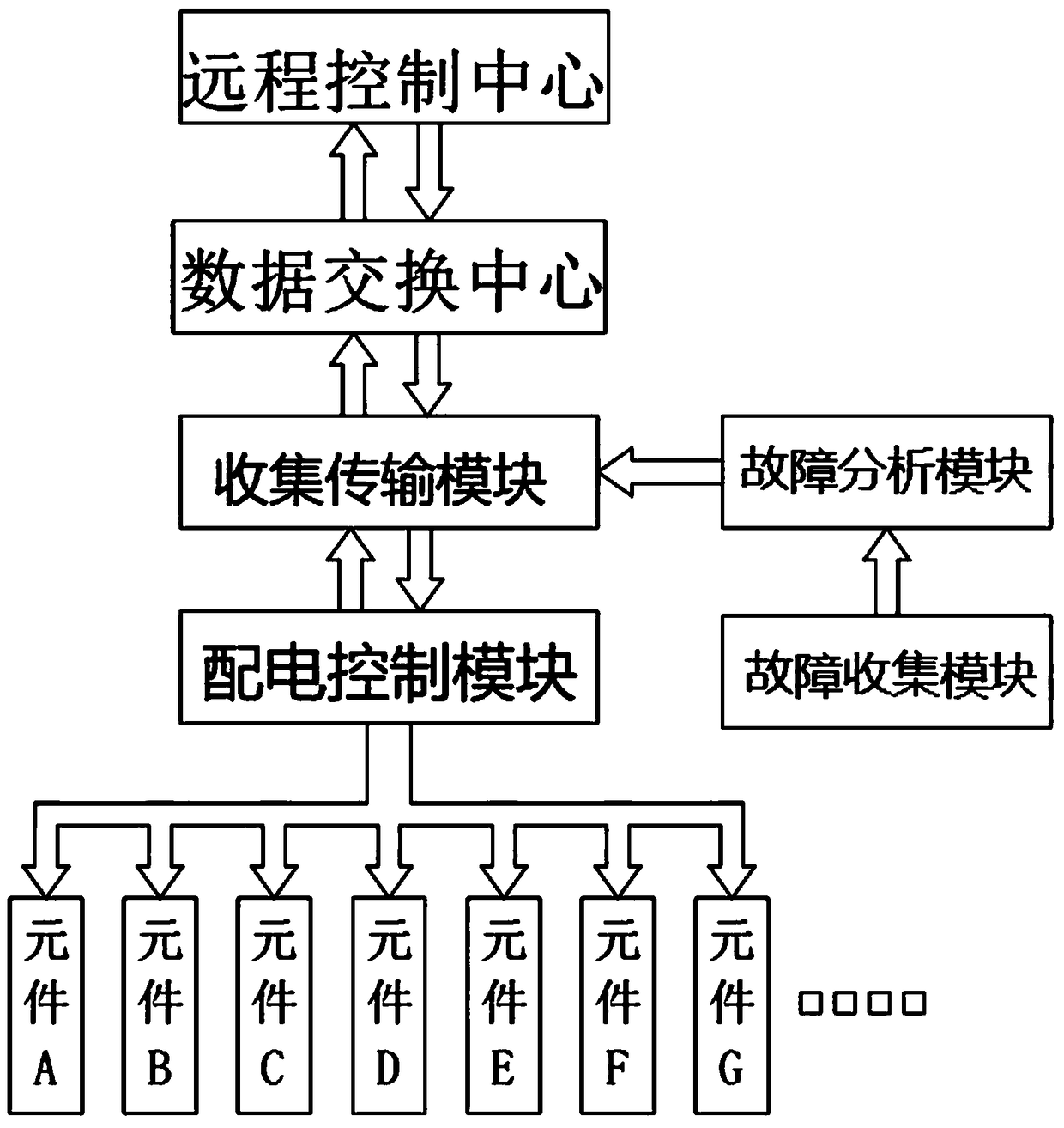

[0016] Such as figure 1 , a remote maintenance system for power distribution automation terminals, including a remote control center, a data exchange center, a collection and transmission module, a power distribution control module, a fault analysis module, a fault collection module, and an automatic control component group; the automatic control component group includes and Several automation elements connected to the power distribution control module.

[0017] The remote control center is used to receive the distribution automation operation information and fault information transmitted by the data exchange center, process the fault, and transmit the processing result to the data exchange center in the form of instructions;

[0018] The data exchange center is used to realize the information transmission between the remote control center and the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com