Anti-bursting chain tooth and zipper with anti-bursting chain tooth

A technology of anti-explosion and chain teeth, applied in the direction of application, sliding fastener components, fasteners, etc., can solve the problems of zipper bursting, stagnation, and heavy sliders, and achieve the effect of reducing the heaviness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

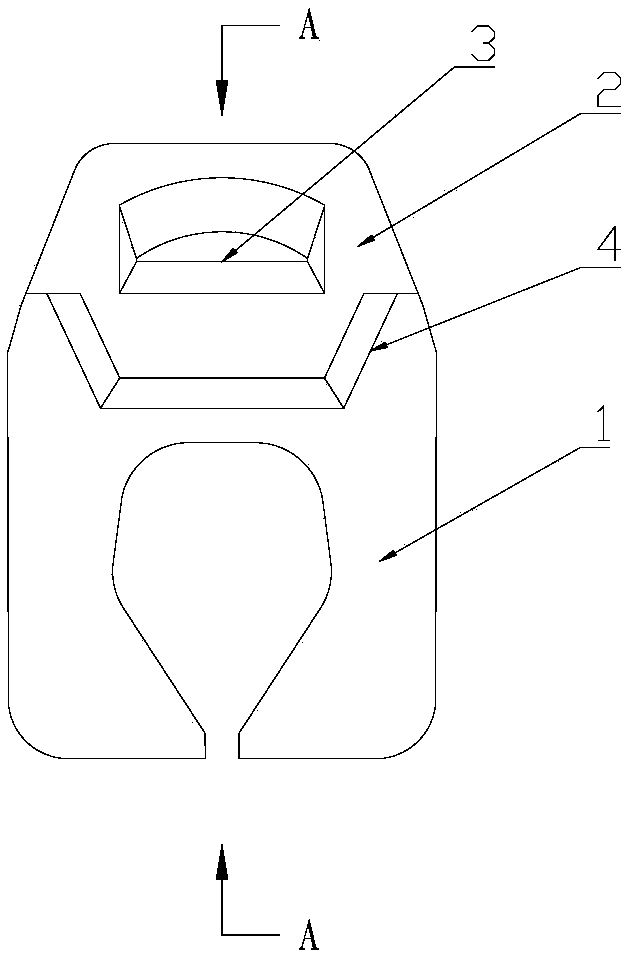

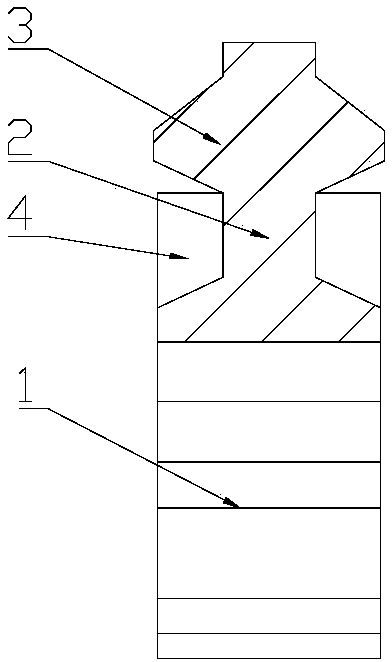

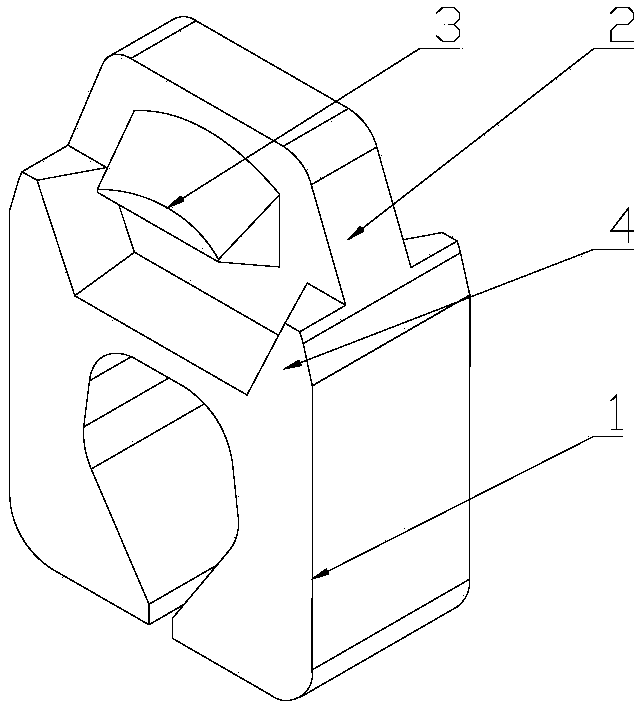

[0042] like Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, an explosion-proof fastener element includes a third tape holding body 10 and a fourth tape holding body 11 adjacent to the third tape holding body 10, and the top of the third tape holding body 10 There is a third tension plate 20, a third protrusion 30 and a third groove 40 on one side of the third tension plate 20, and a third protrusion with interchangeable positions on the other side of the third tension plate 20 30 and the third groove 40, the top of the fourth tape holding body 11 is provided with a fourth tension plate 21, and the side of the fourth tension plate 21 close to the third tension plate 20 is provided with a corresponding third protrusion 30 The fourth groove 60 and the fourth protrusion 50 corresponding to the third groove 40 are provided with the fourth groove 60 and the fourth groove 60 and the fourth groove 60 and the fourth groove 60 and the fourth groove 60 and the...

Embodiment 2

[0051] like Figure 17 and Figure 18 As shown, the zipper using this anti-break fastener element is different from the first embodiment in that the tail end of one piece of cloth tape 70 is provided with a third insert tube 120, and the end end of the other piece of cloth tape 70 is provided with a third intubation tube 120. The second socket 130 corresponding to the third cannula 120, the second socket 130 is provided with a slot corresponding to the third cannula 120, so that the user can quickly find the starting end of the pulling and closing, the rest is the same as the first embodiment, There is no special limitation here, which also belongs to the protection scope of the present invention. The production process is also the same as that in Example 1, and will not be repeated here.

Embodiment 3

[0053] Compared with Embodiment 1, the difference is that the shapes of the third protrusion 30 and the fourth protrusion 50 are either cuboid, cylindrical or conical, the third groove 40 and the fourth groove 60 The shape is either a rectangular parallelepiped groove, a cylindrical groove or a conical groove, and the rest are the same as those in Example 1, and are not particularly limited here, which also belong to the protection scope of the present invention. The production process is also the same as that in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com