Method for preparing pH-sensitive cellulose ether and ester medicament-carrying electrospinning fibers

A technology of mixed ether ester and electrospinning, applied in the field of polymer chemistry, to achieve the effect of large specific surface area, simple operation process and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Prepare the solution

[0040] At room temperature, dissolve HPMCP and drug tetracycline in a mixed solvent composed of absolute ethanol / dichloromethane (1:1, v / v), and prepare concentrations of 10% to 18% respectively in 50mL iodine measuring bottles. % electrospinning solutions are about 15 mL each, wherein HPMCP:tetracycline=20:1 (mass ratio).

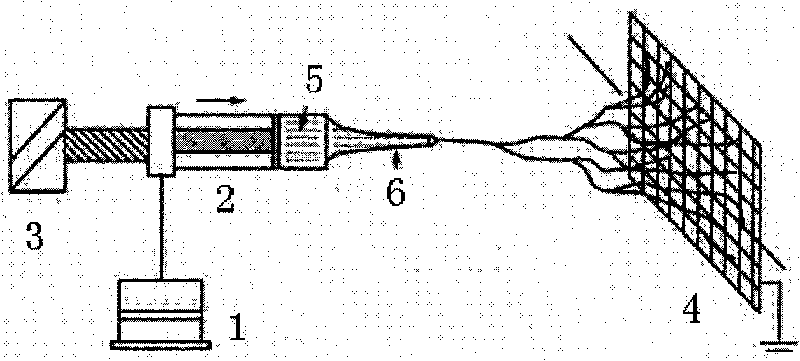

[0041] 2) Electrospinning

[0042] refer to figure 1 , at room temperature, the spinning solution was injected into a 20mL glass syringe, and the metal needle at the front end of the syringe was connected to a high-voltage power supply. The spinning solution was extruded at a rate of 2 mL / h through a syringe pump with set parameters. After turning on the high-voltage power supply and setting the voltage at 15kv, under the action of the electrostatic field force, the polymer solution flow is continuously stretched while flying to the grounded aluminum foil receiving plate, and at the same time the solvent volatilizes to ...

Embodiment 2

[0047] 1) Prepare the solution

[0048] At room temperature, dissolve HPMCAP and drug tetracycline in a mixed solvent composed of absolute ethanol / dichloromethane (1:1, v / v), and prepare a concentration of 9% to 15% in a 50mL iodine bottle. Each of the electrospinning solutions is about 15 mL, wherein HPMCAP:tetracycline=20:1 (mass ratio).

[0049] 2) Electrospinning

[0050] refer to figure 1 , at room temperature, the spinning solution was injected into a 20mL glass syringe, and the metal needle at the front end of the syringe was connected to a high-voltage power supply. The spinning solution was extruded at a rate of 2 mL / h through a syringe pump with set parameters. After turning on the high-voltage power supply and setting the voltage at 15kv, under the action of the electrostatic field force, the polymer solution flow is continuously stretched while flying to the grounded aluminum foil receiving plate, and at the same time the solvent volatilizes to finally obtain u...

Embodiment 3

[0054] 1) Prepare the solution

[0055] At room temperature, HPMCT and the drug tetracycline were dissolved in a mixed solvent composed of anhydrous methanol / dichloromethane (1:5, v / v), and a series of concentrations of electrospinning were prepared in 50 mL iodine flasks. Each solution is about 15 mL, wherein HPMCAT:tetracycline=20:1 (mass ratio).

[0056] 2) Electrospinning

[0057] refer to figure 1 , at room temperature, the spinning solution was injected into a 20mL glass syringe, and the metal needle at the front end of the syringe was connected to a high-voltage power supply. The spinning solution was extruded at a rate of 2 mL / h through a syringe pump with set parameters. After turning on the high-voltage power supply and setting the voltage at 15kv, under the action of the electrostatic field force, the polymer solution flow is continuously stretched while flying to the grounded aluminum foil receiving plate, and at the same time the solvent volatilizes to finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com