Intelligent multi-direction jet spherical fire-extinguishing apparatus

A fire extinguishing device, spherical technology, applied in fire rescue and other directions, can solve the problems of slow injection speed, easy falling, poor dispersion, etc., to avoid long-term storage, high fire extinguishing efficiency, and fast detonation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

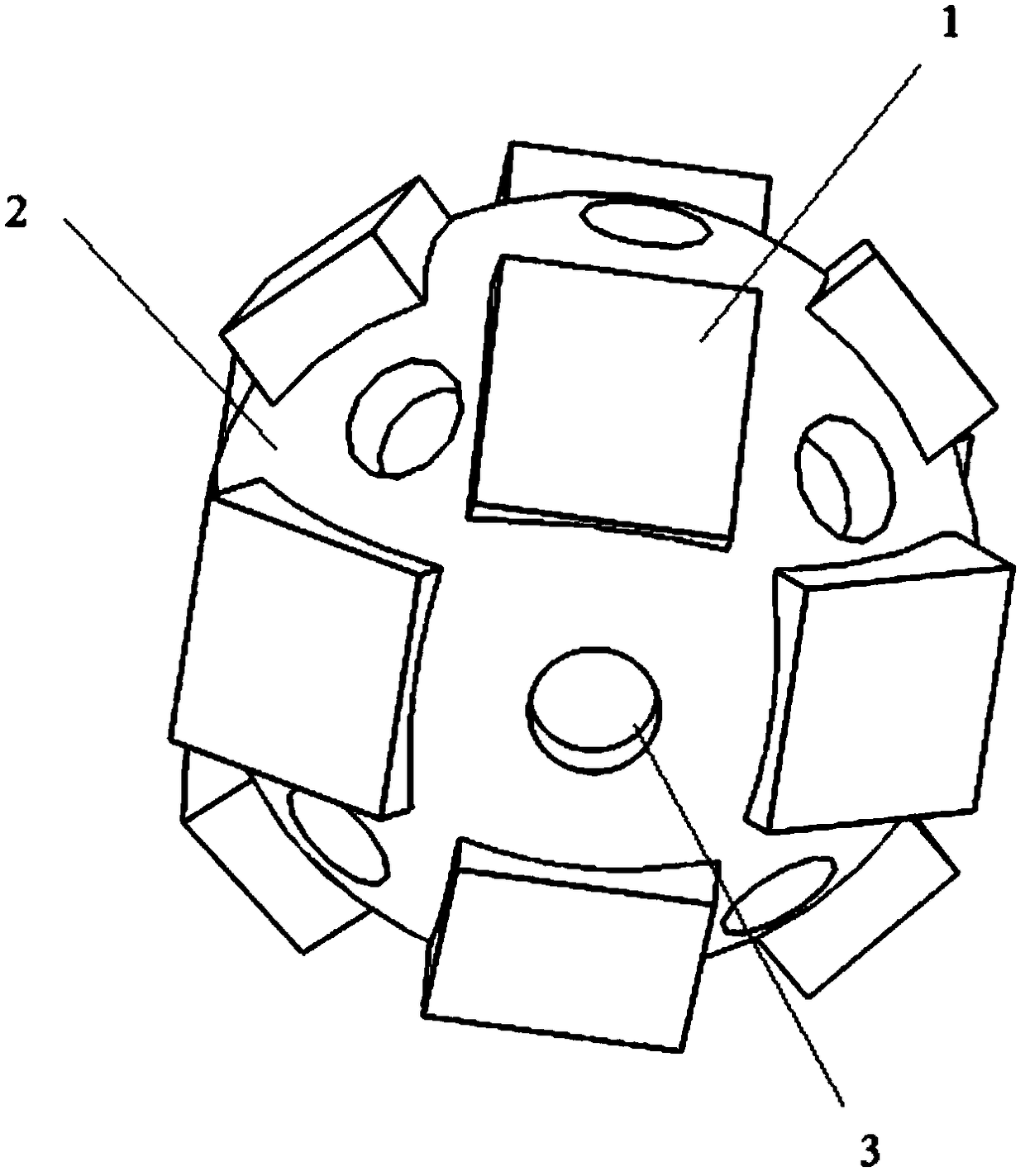

[0030] See attached figure 1 , 2 , 3. An intelligent multi-directional spray spherical fire extinguishing device, comprising: a spherical shell 2, an intelligent trigger controller 1, a dry powder fire extinguishing agent 5 and a gas generating agent 4;

[0031] Six injection holes 3 are evenly distributed on the spherical shell 2 (spherical or ellipsoidal), and the injection holes 3 are sealed by aluminum foil; in this example, the spherical shell 2 is made of explosion-proof carbon steel, and the thickness is enough to withstand the fire extinguishing agent injection process. High pressure generated without significant deformation.

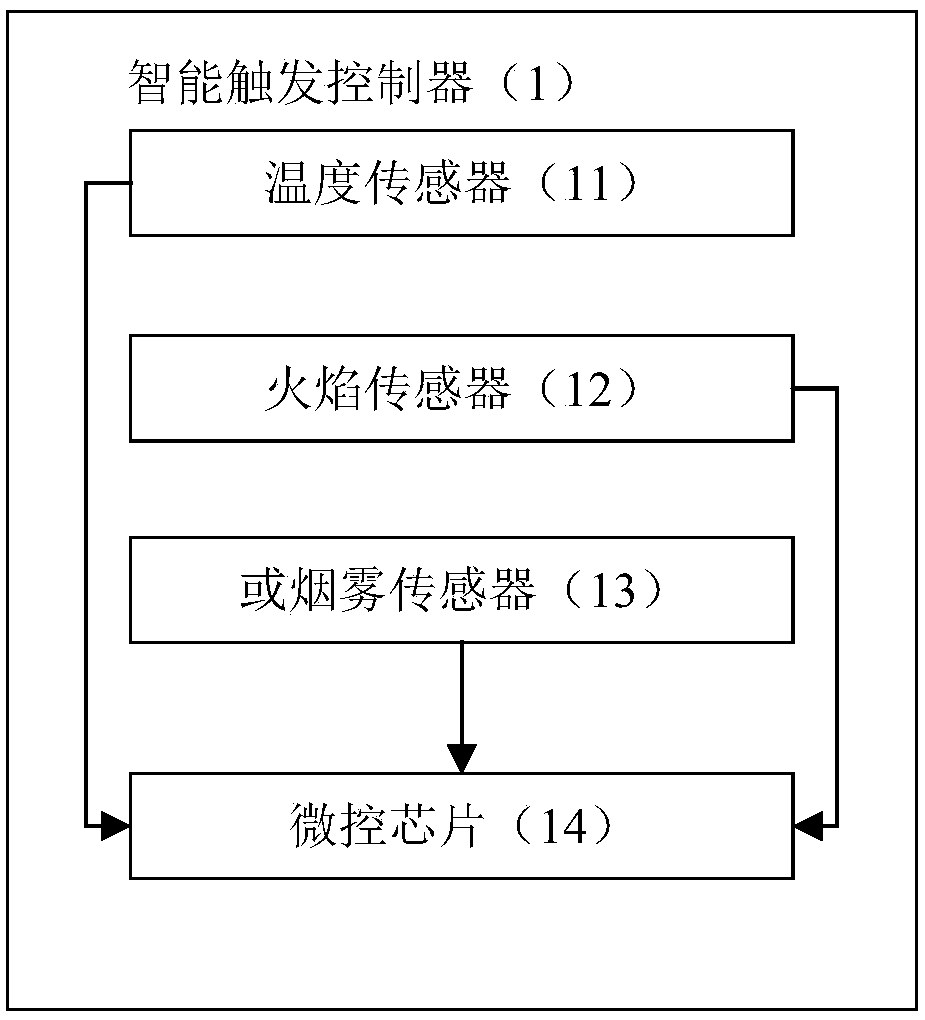

[0032] The intelligent trigger controller 1 is installed on the spherical housing 2 and includes: a fire detection sensor and a micro-control chip 14 connected with the fire detection sensor; the micro-control chip 14 judges whether a fire occurs according to the transmission signal of the fire detection sensor; Fire detection sensors include ...

Embodiment 2

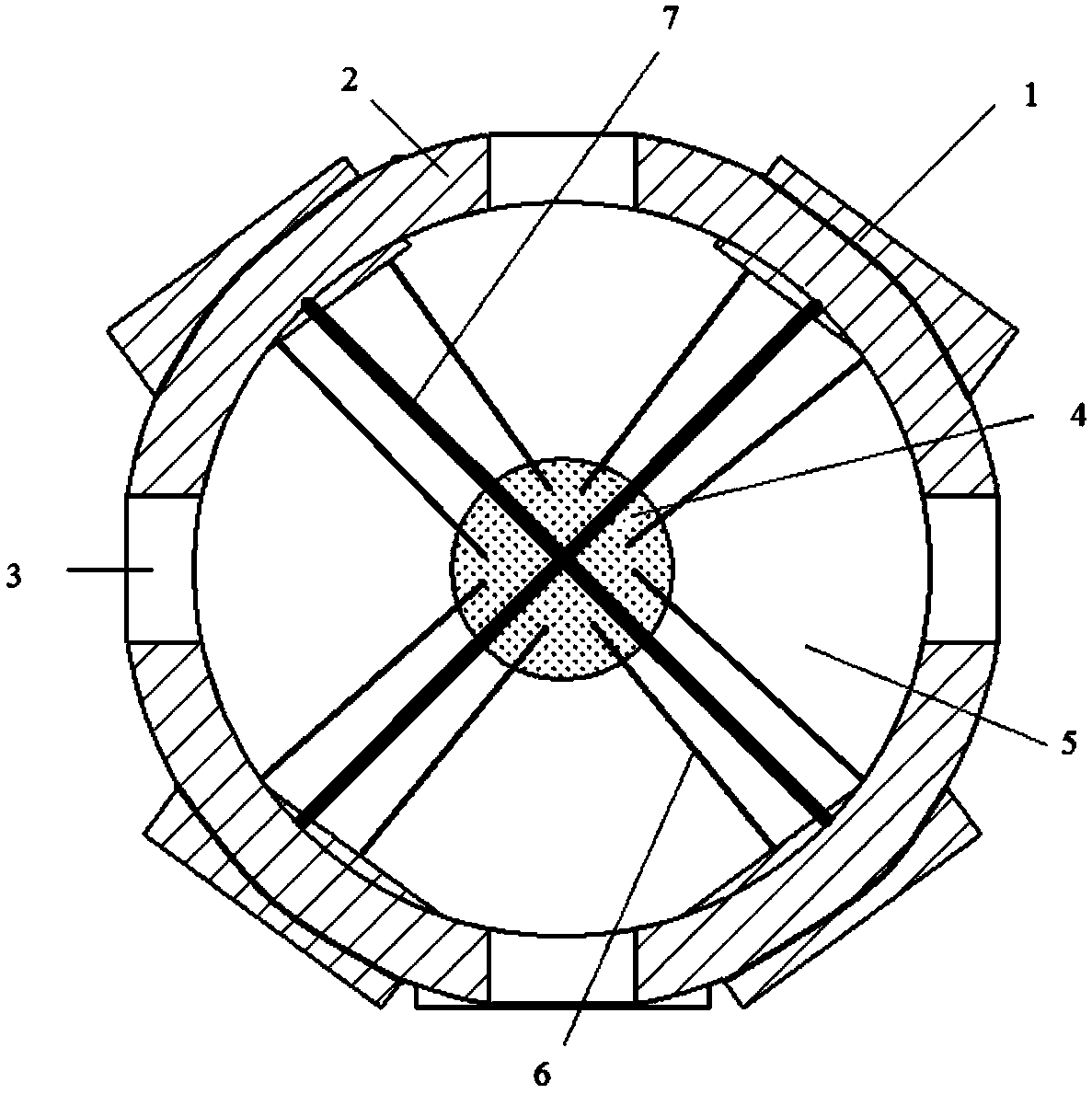

[0040]On the basis of Embodiment 1, further, a single intelligent trigger controller 1 is used to control a single spray hole 3 to spray dry powder fire extinguishing agent 5 to achieve the effect of directional spray fire extinguishing, specifically: set six spray holes 3 one A corresponding smart trigger controller 1 , each smart trigger controller 11 controls one injection port 3 , and the micro-control chip 14 of each smart trigger controller 11 is connected to the gas generating agent 4 through an electric ignition wire 6 . Based on this, the dry powder fire extinguishing agent 5 inside the spherical housing 2 is divided into six areas by the carbon structure barrier 7, and each area corresponds to an intelligent trigger controller 1, an electric ignition wire 6 and an injection port 3.

[0041] When the device is thrown into a small space where the fire occurs, after the intelligent trigger controller 1 (one or more) in the direction of the fire detects the fire, it will ...

Embodiment 3

[0043] On the basis of Embodiment 1, further, adopt an intelligent trigger controller 1 to control the scheme of two injection holes 3, specifically:

[0044] There are three intelligent trigger controllers 1, which are evenly distributed on the surface of the spherical shell 2; the interior of the spherical shell 2 is divided into three areas by the carbon structure barrier 7, and each area corresponds to an intelligent trigger controller 1 and two 3 injection holes. The micro-control chip 14 of each intelligent trigger controller 11 is connected to the gas generating agent 4 through an electric ignition wire 6 .

[0045] Or: the interior of the spherical shell 2 is divided into six areas by the carbon structure grille 7, each area corresponds to an injection hole 3 and an electric ignition wire 6, and every two areas share an intelligent trigger controller 1. The micro-control chip 14 branch of each smart trigger controller 11 is connected to the gas generating agent 4 thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com