Fan-shaped section secondary cooling system for solidification final stage heavy reduction

A solidification end and sector-shaped technology, applied in the field of metallurgy, can solve the problems of roller table transportation damage, affecting the casting billet, warping deformation, etc., and achieve the effect of prolonging the service life, saving equipment costs, and preventing warping and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

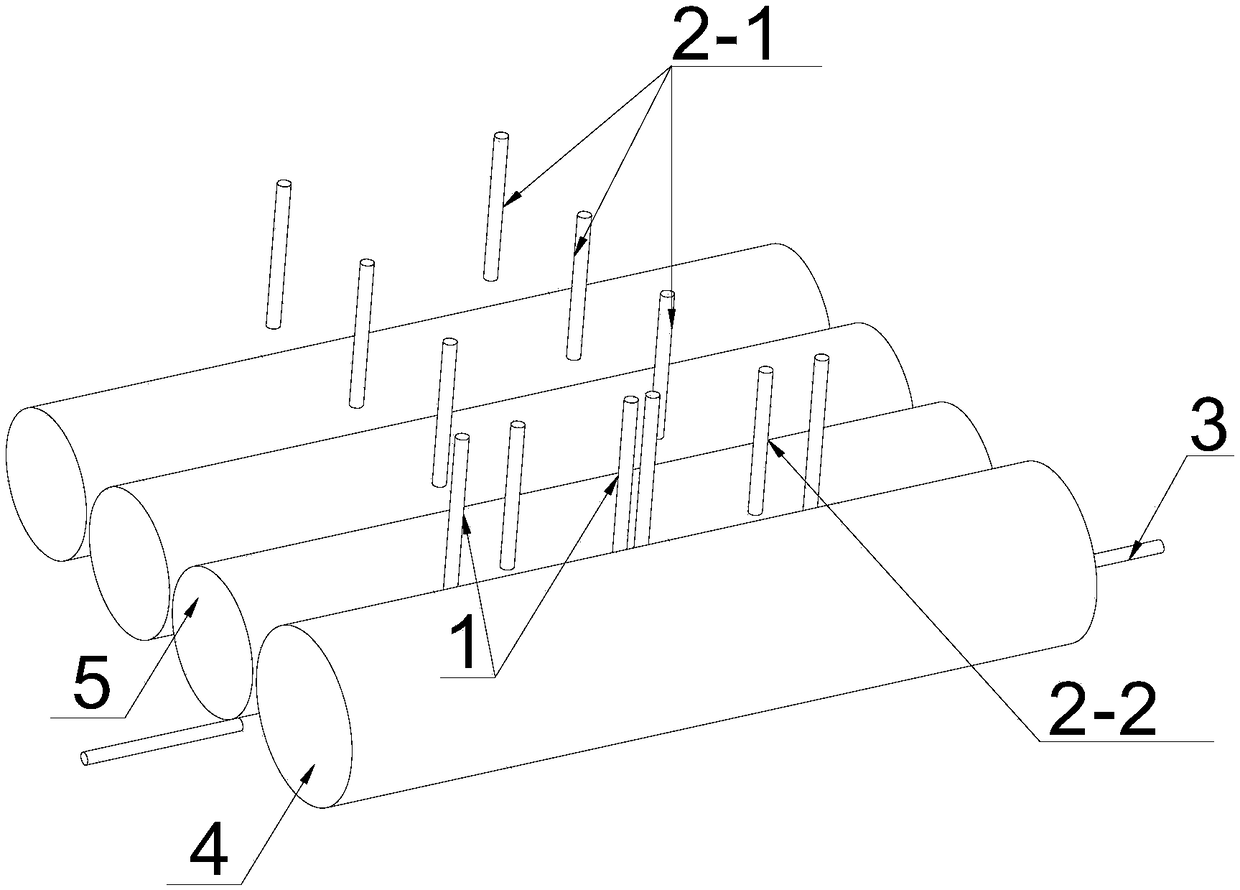

[0027] Such as figure 1 As shown, in the present embodiment, the cooling nozzles (horizontal cooling nozzles 3, vertical cooling nozzles 2-1, vertical cooling nozzles 2-2 with an inclined angle) and strong scale-sweeping nozzles 1 of the inner arc roller section are horizontally and vertically Distributed in a straight and staggered manner, horizontally arranged transverse cooling nozzles 3 are formed between the first roller 4 and the second roller 5, and the two ends of the lower V-shaped groove are arranged opposite to each other along the axial direction of the roller section, and the transverse cooling nozzles 3 and the horizontal plane form a certain angle α (2°≤α≤5°), and the outlet of the transverse cooling nozzle 3 is directed upwards and directed to the lower surface of the inner arc roll section. The effect of adopting the angle is: it can effectively Sweep the iron scale to both sides to prevent the accumulation of iron scale to the center and assist the uniform co...

Embodiment 2

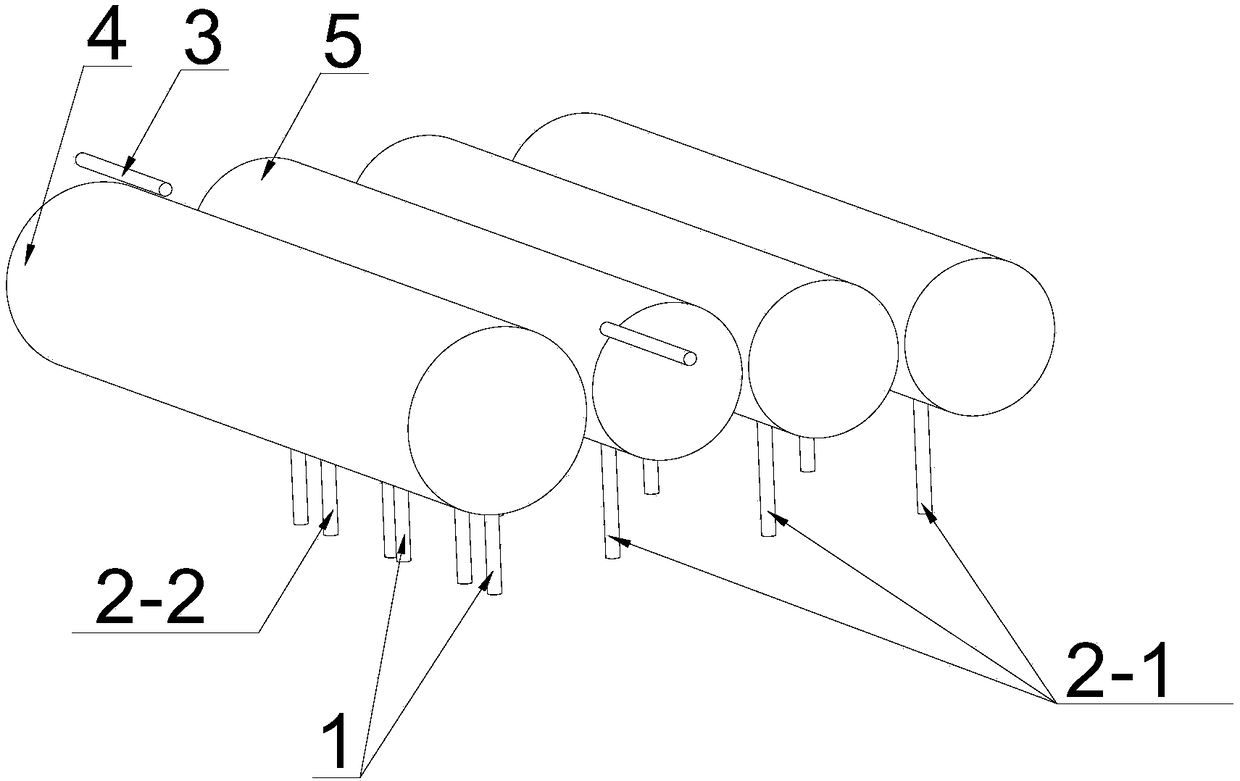

[0031] like figure 2 As shown, the arrangement of the cooling and strong sweeping nozzles of the outer arc roll section is basically the same as that of the inner arc roll section. In this embodiment, the cooling nozzles (horizontal cooling nozzles 3, vertical cooling nozzles 2-1, vertical cooling nozzles 2-2 with an inclined angle) of the outer arc roller section and the strong scale-sweeping nozzles 1 are staggered horizontally and vertically. The horizontally arranged transverse cooling nozzles 3 are formed between the first roller 4 and the second roller 5, and the two ends of the upper V-shaped groove are arranged opposite to each other along the axial direction of the roller section, and the transverse cooling nozzles 3 and the horizontal plane There is a certain included angle α (2°≤α≤5°), and the outlet of the transverse cooling nozzle 3 is directed downwards, pointing to the upper surface of the outer arc roll section. The effect of adopting the included angle is: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com