Printing and glazing integrated printer

A technology for printers and printing areas, applied in typewriters, printing devices, printing, etc., can solve problems such as relying on manual experience, and achieve the effects of improving quality, reducing usage, and precise glazing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

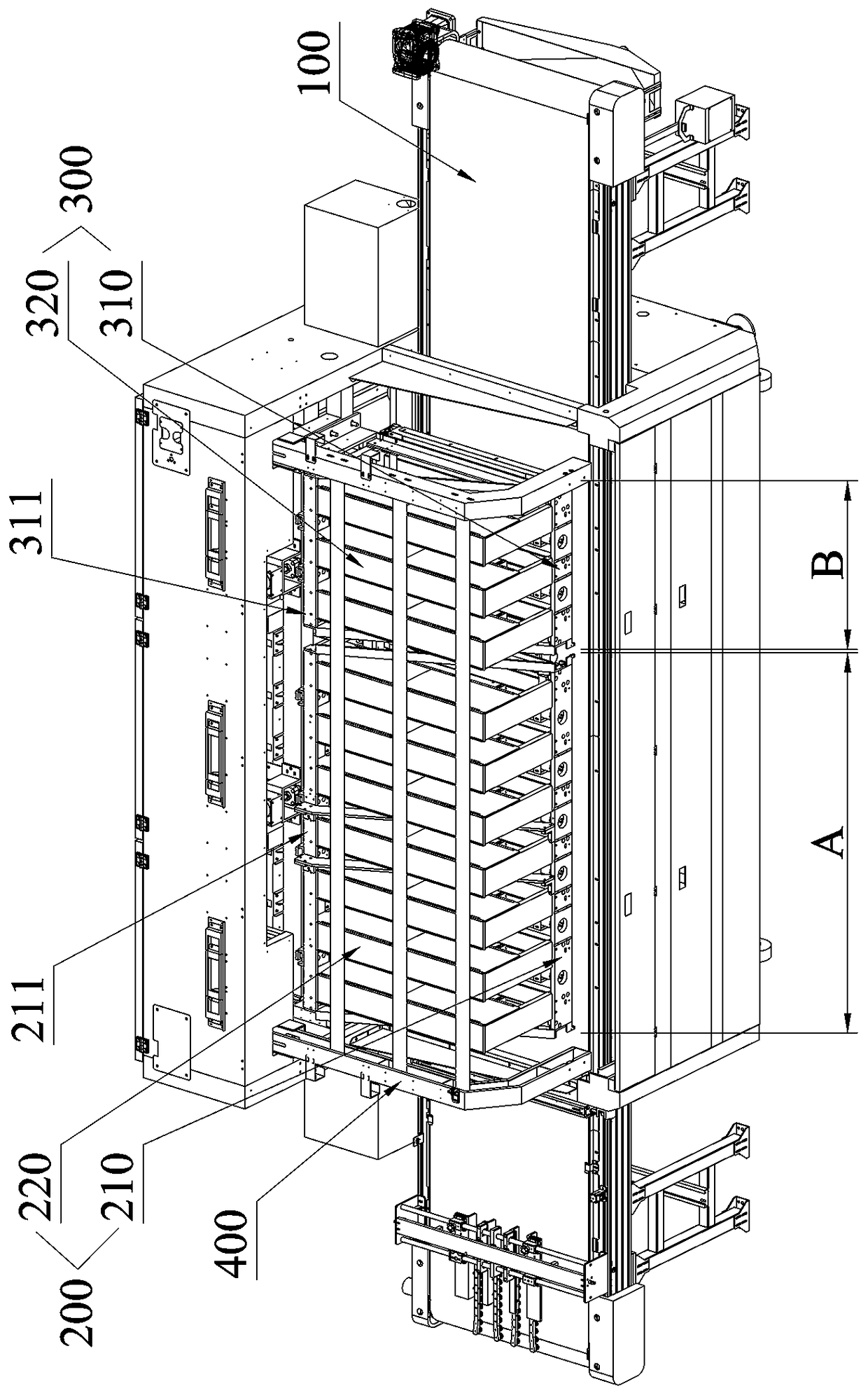

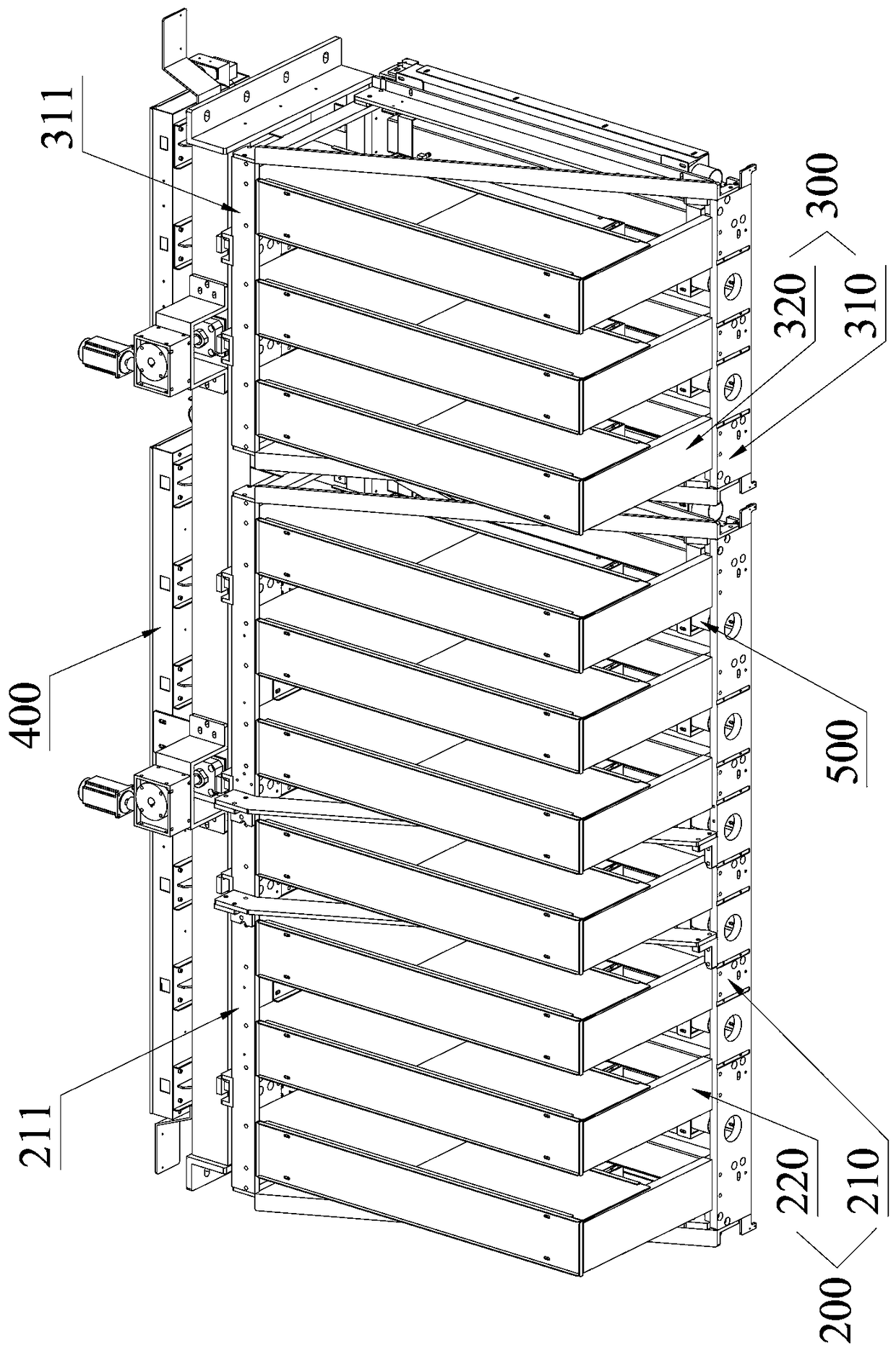

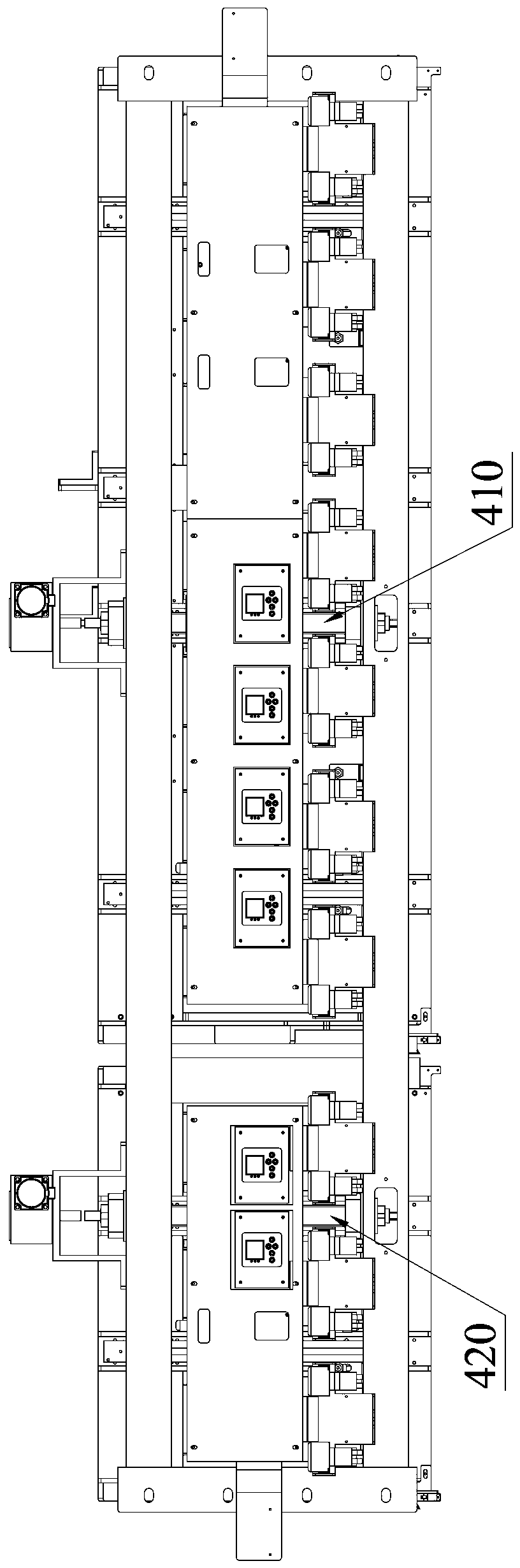

[0025] Such as figure 1 As shown, an integrated printing and glazing printer, the printer is divided into a printing area A and a glazing area B, including a conveying platform 100 that runs through the printing area A and glazing area B in sequence, is set in the printing area A and is located on the conveying platform The printing system 200 above 100, and the glazing system 300 arranged in the glazing area B and above the conveying platform 100, the glazing system 300 at least includes a pair of full-format printing channels.

[0026] This patent adopts the method of printing to replace the traditional glaze and spray glaze to achieve refined production, the amount of glaze used is greatly reduced, the utilization rate of glaze is almost 100%, and a large amount of waste is avoided. The glazing process is accurate to microns Level, will not cause pollution to the working environment. The printing process and the glazing process are put on the same printer, and the printing...

Embodiment 2

[0032] Such as Figure 4 As shown, an integrated printing and glazing printer, the printer is divided into a printing area A and a glazing area B, including a conveying platform 100 that runs through the printing area A and glazing area B in sequence, is set in the printing area A and is located on the conveying platform The printing system 200 above 100, and the glazing system 300 arranged in the glazing area B and above the conveying platform 100, the glazing system 300 at least includes a pair of full-format printing channels.

[0033] This patent adopts the method of printing to replace the traditional glaze and spray glaze to achieve refined production, the amount of glaze used is greatly reduced, the utilization rate of glaze is almost 100%, and a large amount of waste is avoided. The glazing process is accurate to microns Level, will not cause pollution to the working environment. The printing process and the glazing process are put on the same printer, and the printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com