Shear rotary valve and oil immersion type shear rotary valve plunger pump comprising same

A plunger pump and oil-immersed technology, which is applied in the field of oil-immersed shear rotary valve plunger pumps, can solve the problems of stuck or stalled valve cores and reduced feeding accuracy, and achieve improved feeding accuracy and good The effect of feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

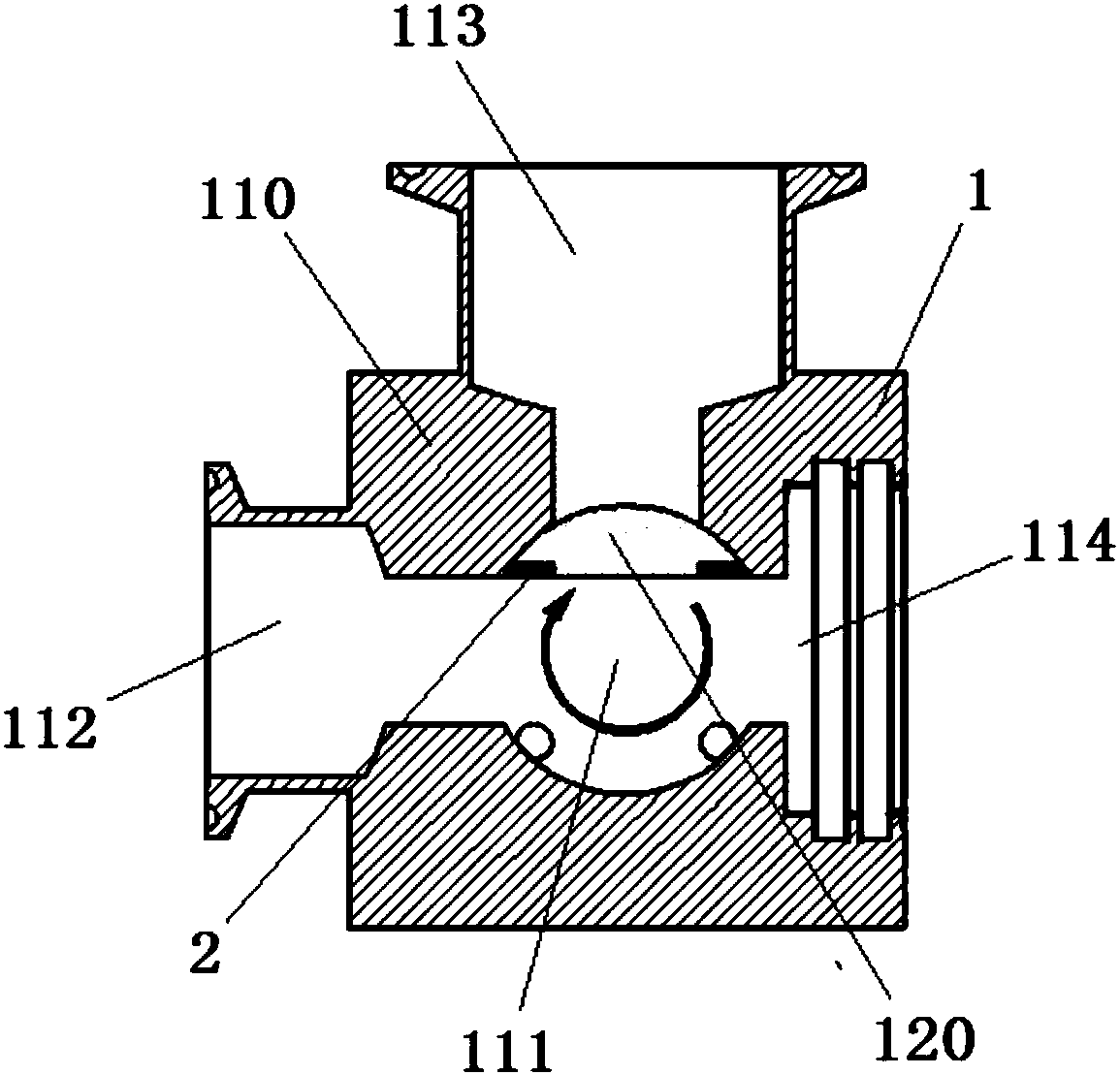

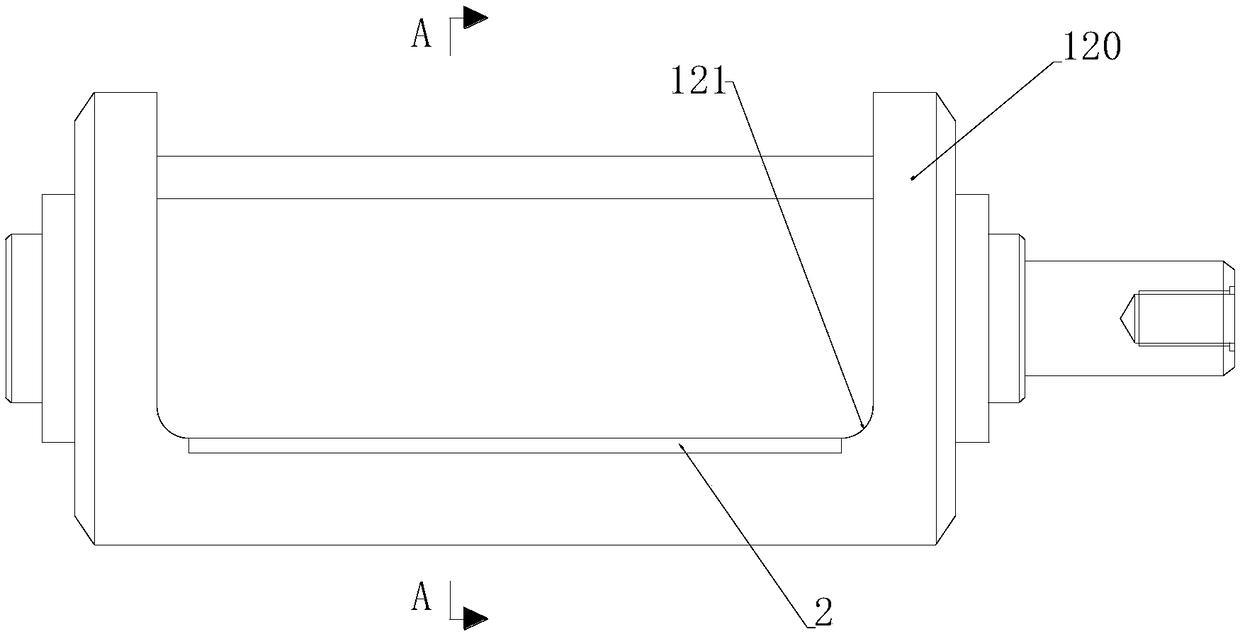

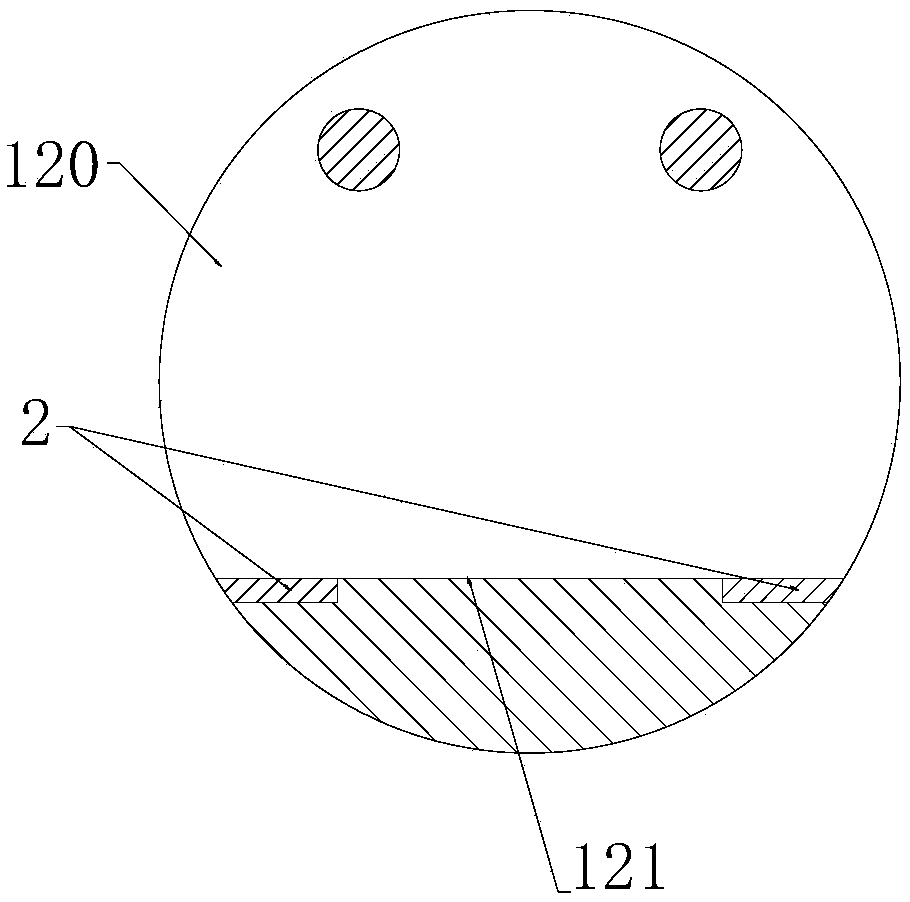

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a shearing rotary valve includes a valve body 110 and a valve core 120 disposed in the valve cavity 111 of the valve body 110, wherein both ends of the valve core 120 are rotatably connected with the valve body 110, and on the valve body 110 A material outlet 112, a first material inlet 113 and a second material inlet 114 communicating with the valve cavity 111 are provided, the material outlet 112 is arranged horizontally, the second material inlet 114 is arranged horizontally, and the first material inlet 113 Vertically arranged, the angle between the discharge port 112 and the first feed port 113 is 90°, the valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com