Sealing device for internal mixer

A technology of sealing device and internal mixer, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of reducing processing efficiency, machine pressure relief, material waste, etc., to extend the leakage path, prevent material leakage, seal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with specific embodiment, see figure 1 -5:

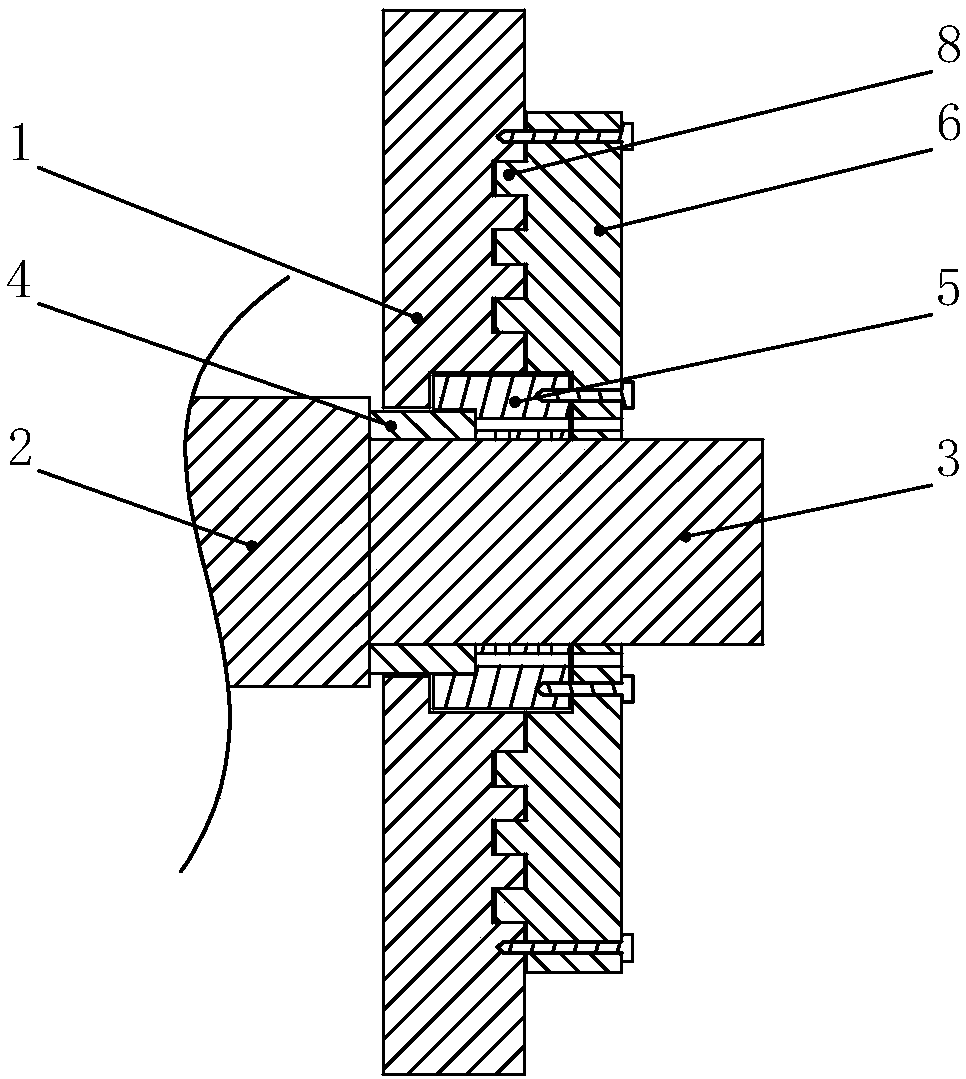

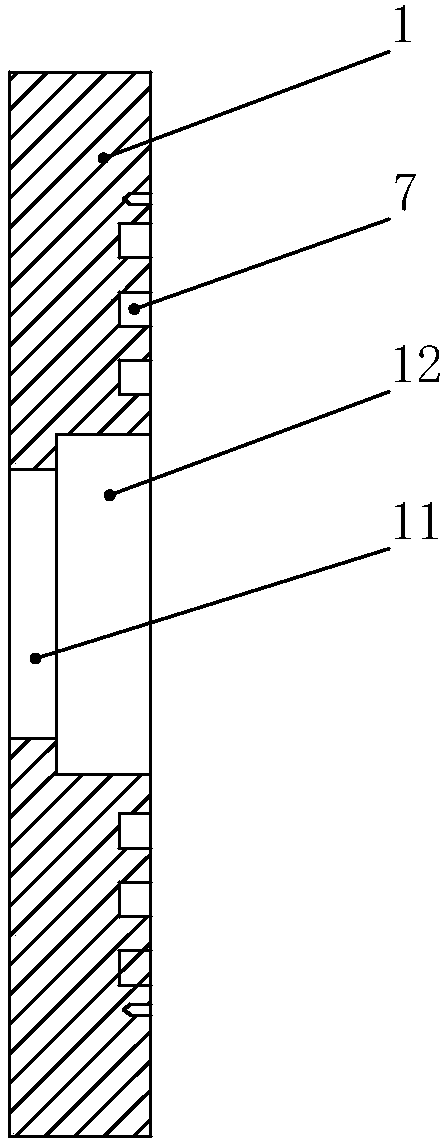

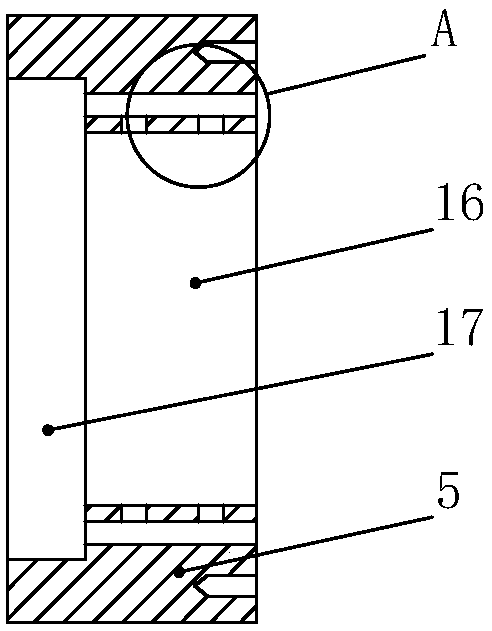

[0026] A sealing device for an internal mixer, comprising a internal mixing chamber 1 and a rotor 2, the end of the rotor 2 is provided with a rotating shaft 3, the side wall of the internal mixing chamber 1 is provided with a bearing hole, and the rotating shaft 3 is far away from The rotor 2 is sequentially provided with a dynamic sealing ring 4, a static sealing ring 5 and a gland 6. The dynamic sealing ring 4 and the static sealing ring 5 are arranged in the inner cavity of the bearing hole, and the dynamic sealing ring 4 is in contact with the end surface of the rotor 2. , the gland 6 is fixedly connected with the outer wall of the mixing chamber 1 through fasteners, and the gland 6 is also fixedly connected with the static sealing ring 5 through fasteners. The outer wall of the mixing chamber 1 takes the center of the bearing hole as the center More than two annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com