Special automatic unhooking and hooking device for acid mist room

A decoupling and automatic technology, applied in the direction of lifting device, engine components, engine sealing, etc., can solve the problem of unsteady operation of sling equipment, achieve the effect of protecting from corrosion, protecting operators, and ensuring sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

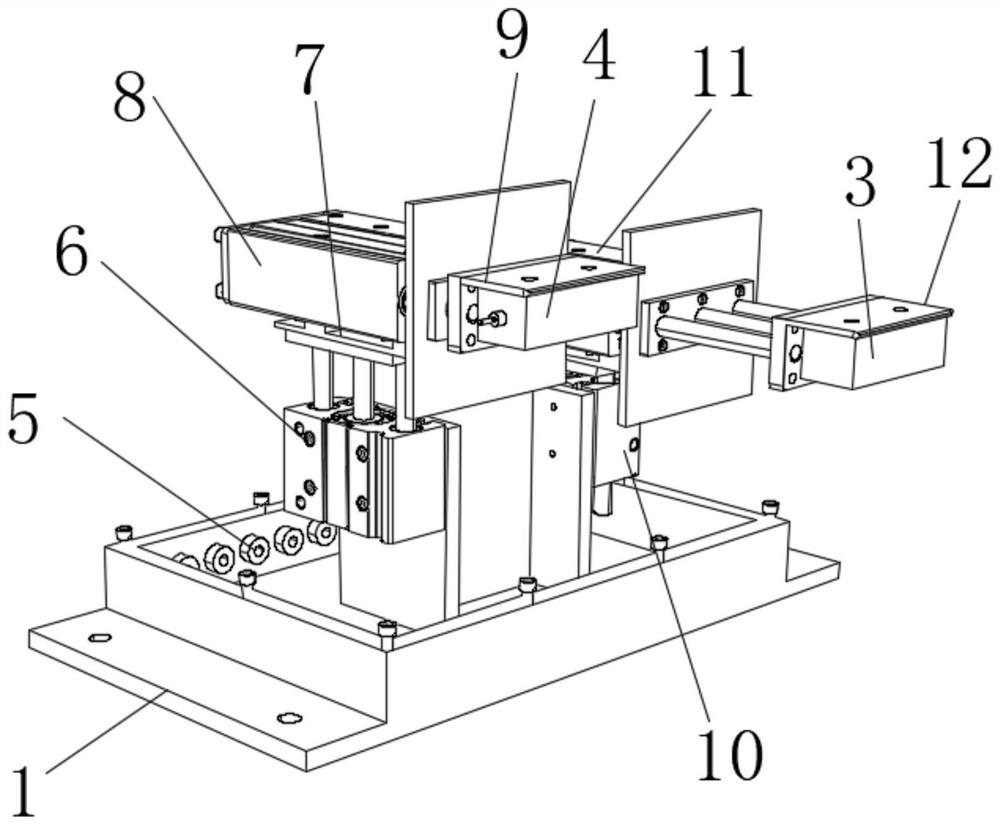

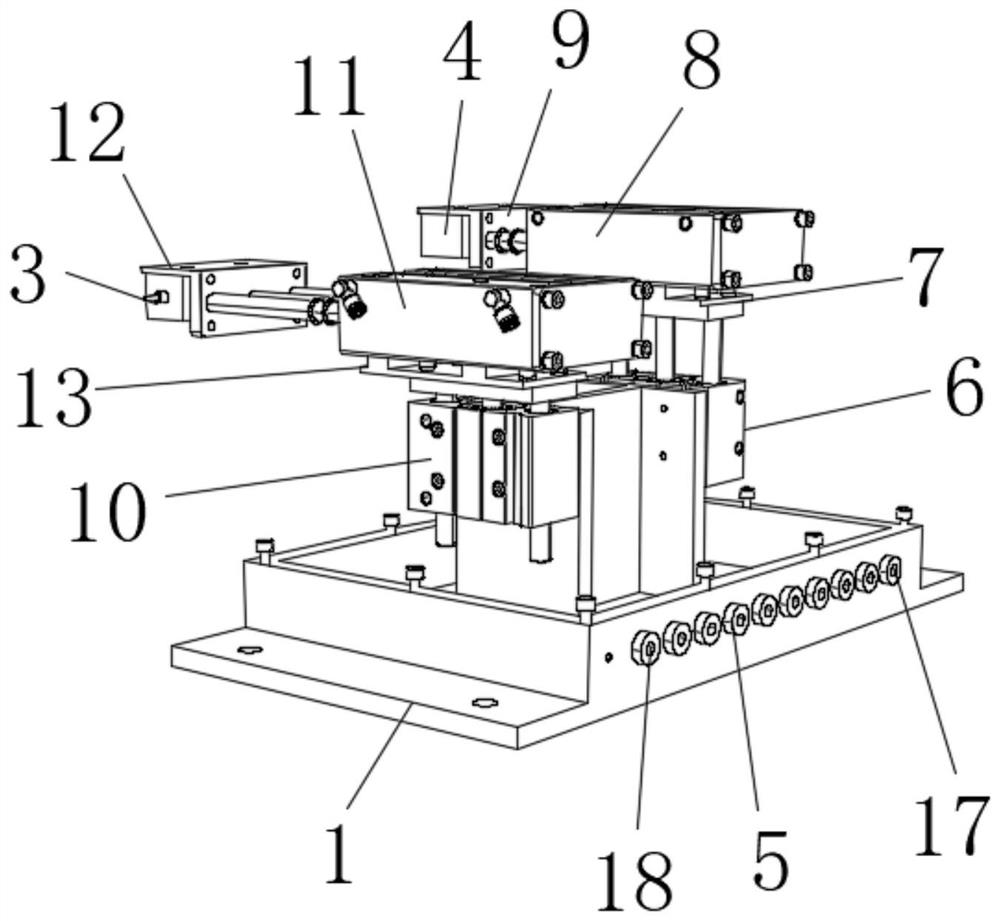

[0034] In order to solve the problem that the existing technology requires personnel to frequently enter and exit the closed room to manually replace the sling, which is dangerous and occupationally harmful, such as figure 1 and figure 2As shown, the embodiment of the present invention provides a special automatic decoupling device for acid mist rooms, including an installation base 1, which is used for external installation of equipment and a fixing seat for internal mechanisms;

[0035] The top of the installation base 1 is fixedly connected with a lifting mechanism, and the top of the lifting mechanism is fixedly connected with a telescopic mechanism, and the output end of the telescopic mechanism is provided with an electromagnet assembly, which can complete the work of removing and hanging the hanger straps in the steel pipe galvanizing process.

[0036] The lifting mechanism includes a first three-axis cylinder 10 for lifting and a second three-axis cylinder 6 for lifti...

Embodiment 2

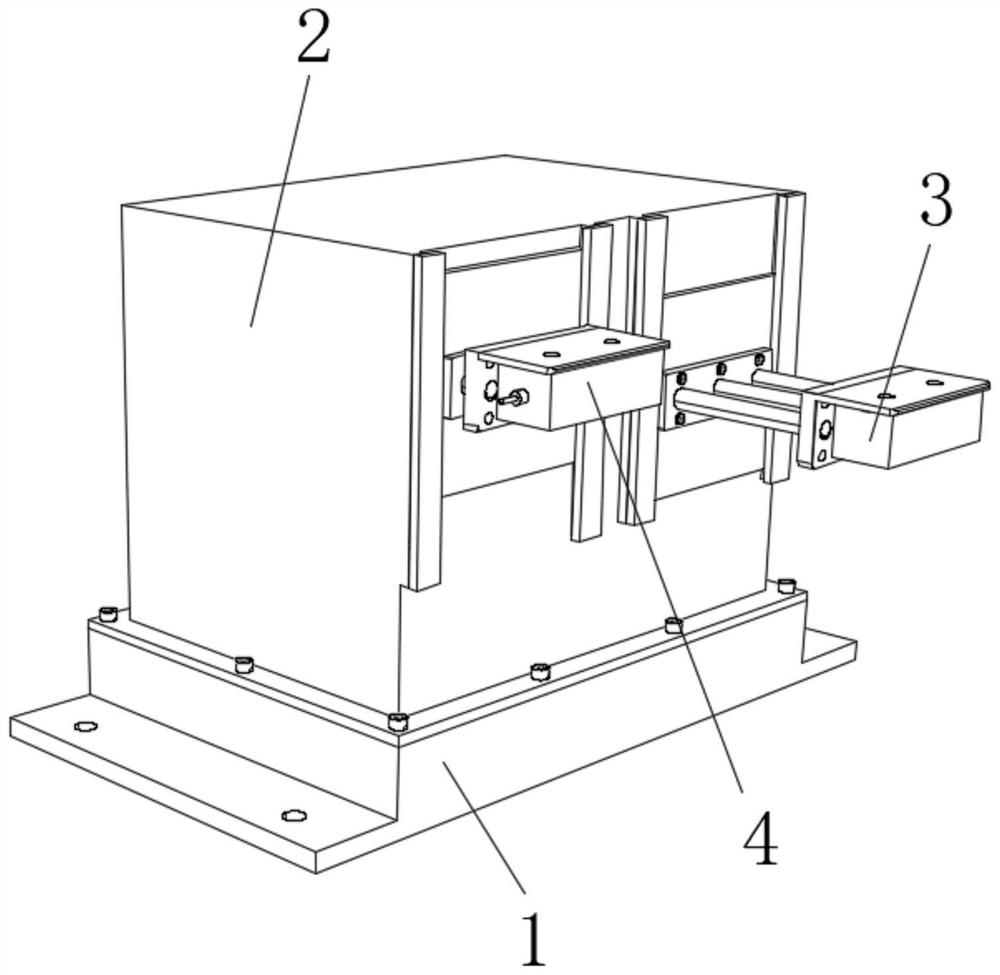

[0044] On the basis of the above embodiments, in order to solve the problem that the equipment cannot operate stably for a long time in the environment of acid mist, such as Figure 3-Figure 5 As shown, the embodiment of the present invention provides a special automatic decoupling device for acid mist rooms, which also includes a micro-positive pressure protective cover system. The micro-positive pressure protective cover system includes a sealing cover 2, a row of threaded holes 5 and a moving sealing assembly. It can prevent the infiltration of hydrochloric acid mist in the external environment. The sealing cover 2 is used for sealing and protecting the internal components of the cover. In the side, one of the threaded hole columns 5 is an air outlet hole 18, and the other threaded hole column 5 is an air inlet hole 17. The aperture of the air inlet hole 17 is larger than the aperture of the air outlet hole 18, and the air outlet resistance is large, and the remaining thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com