High-pressure channelization sealing slurry valve

A technology of high-pressure pipeline and sealing material, applied in the direction of lift valve, valve device, engine components, etc., can solve problems such as shortening valve life, and achieve the effect of prolonging leakage path, prolonging shutdown and maintenance period, and huge economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

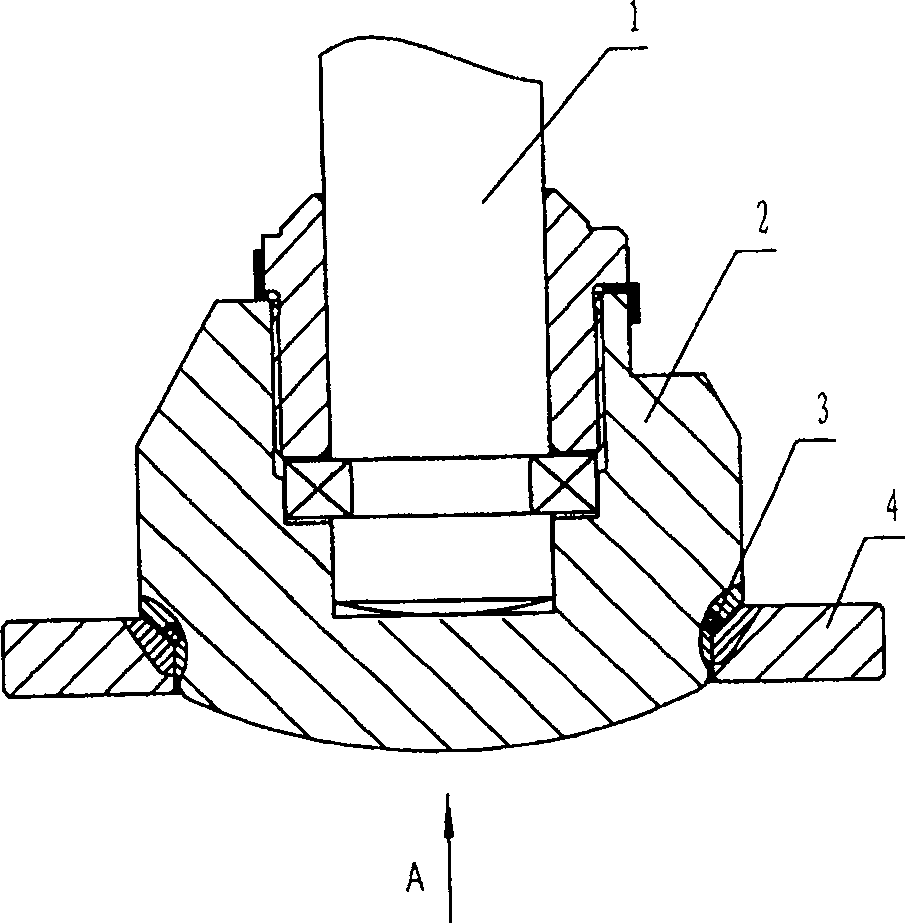

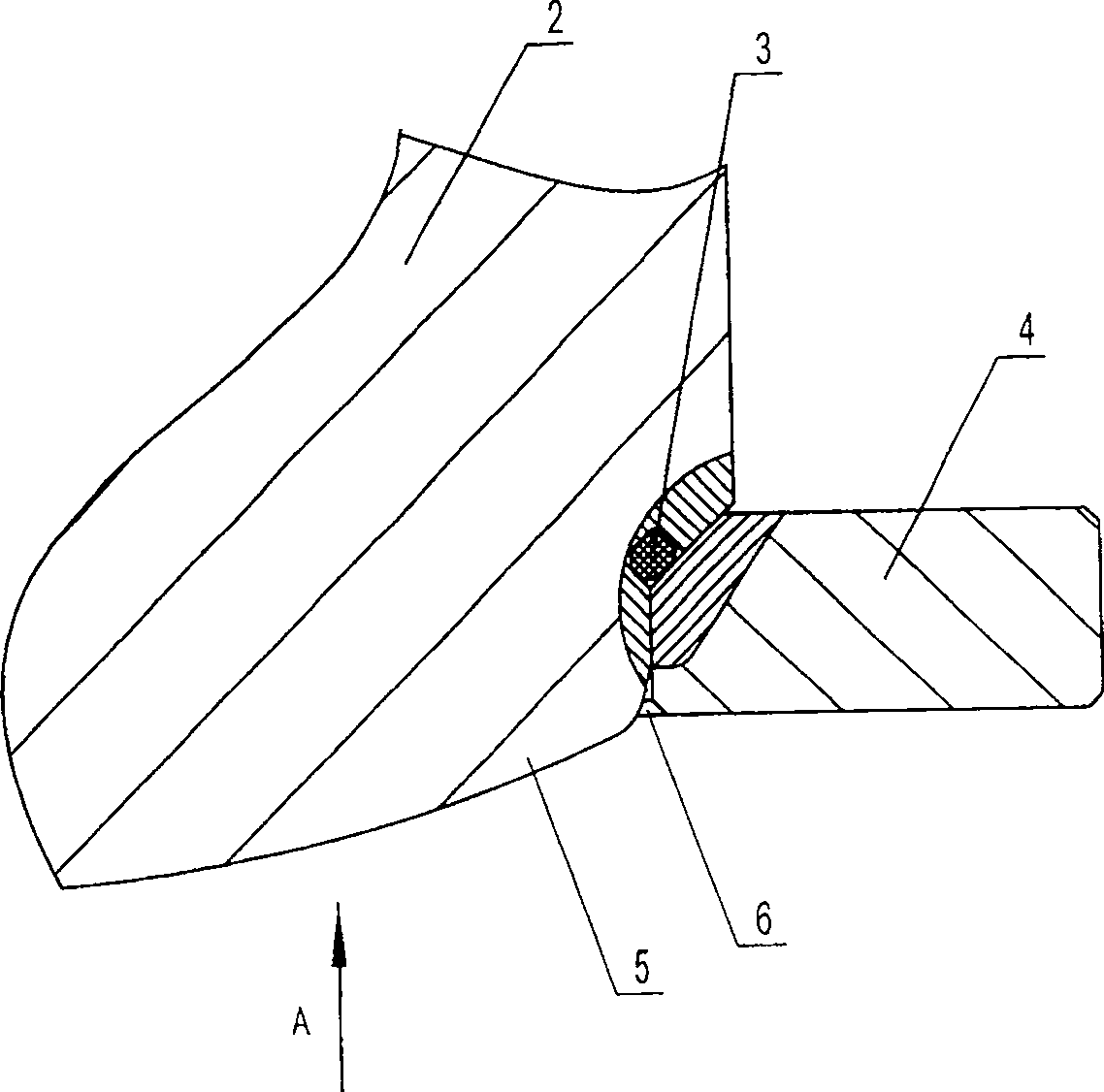

[0016] The high-pressure pipeline sealing slurry valve as shown in the figure includes a valve disc 2, a valve stem 1 connected to the valve disc, and a valve seat 4 sealingly matched with the valve disc. The lower part of the valve disc 2 is provided with a Sealing port guide device, the seal port guide device includes a bent part 5 formed at the lower part of the valve disc at the valve seat, and there is an axially arranged secondary seal between the side wall of the bent part 5 and the valve seat pair, the pair of sealing pairs adopts plane and plane sealing, and a diversion port 6 is formed at its lower part. A main sealing pair is formed between the valve seat and the disc, which is located above the flow guiding device at the sealing port. It adopts a spherical surface-to-spherical sealing structure made of tungsten carbide, and the radius of the two sealing spherical surfaces is the same. A high temperature resistant "O" type rubber sealing ring 3 is provided on the ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com