A Piston Ring Structure Suitable for Miniature Oil-free Compressors to Operate in Wide Conditions

A compressor and piston ring technology, which is applied in the field of piston ring structure, can solve the problems of increased leakage of the compressor and unsatisfactory effects, and achieves the effect of ensuring the sealing performance and achieving remarkable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] For ease of understanding, the specific structure and working mode of the present invention are further described below:

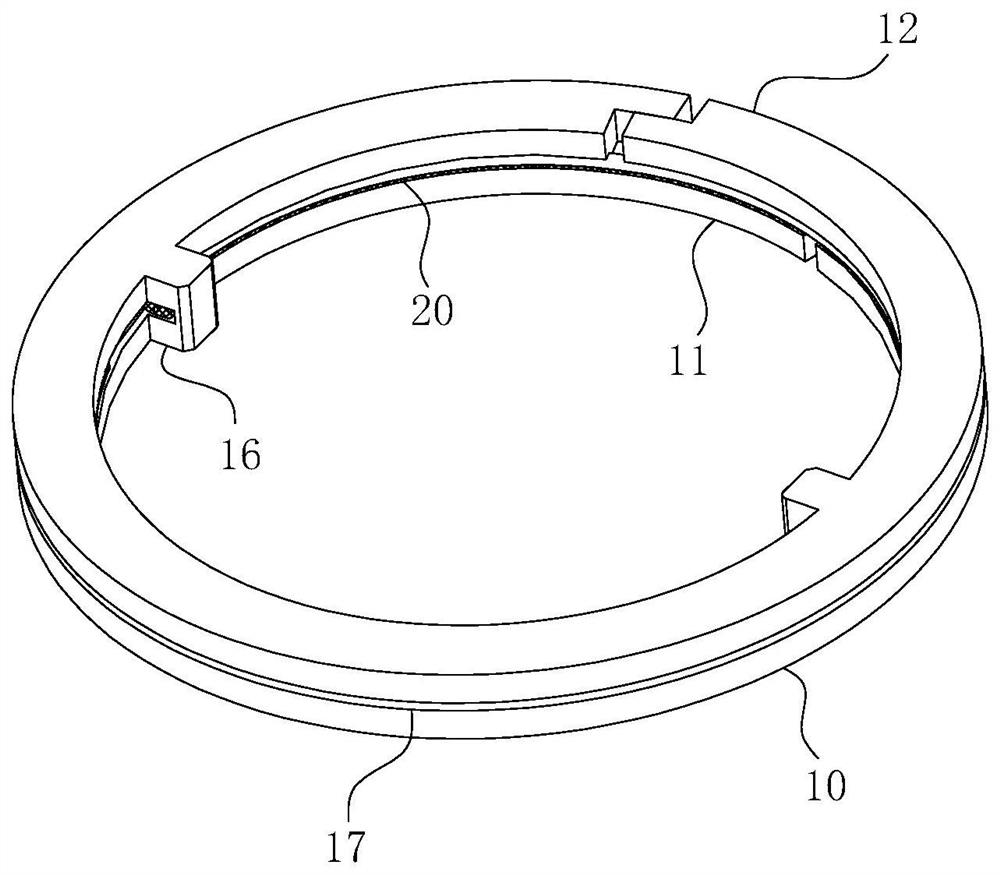

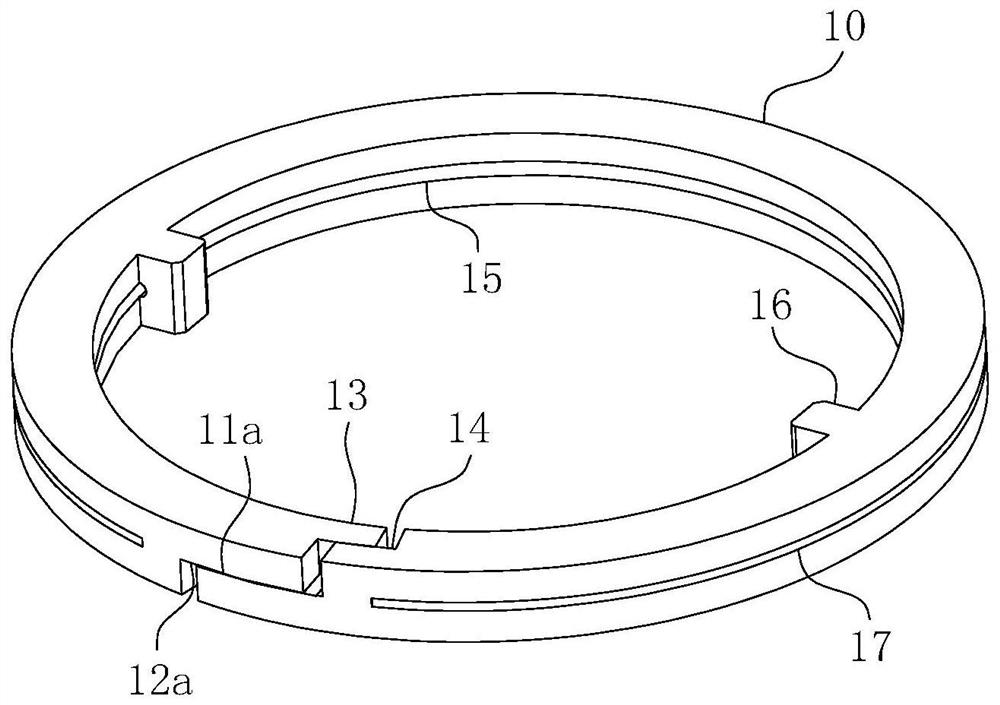

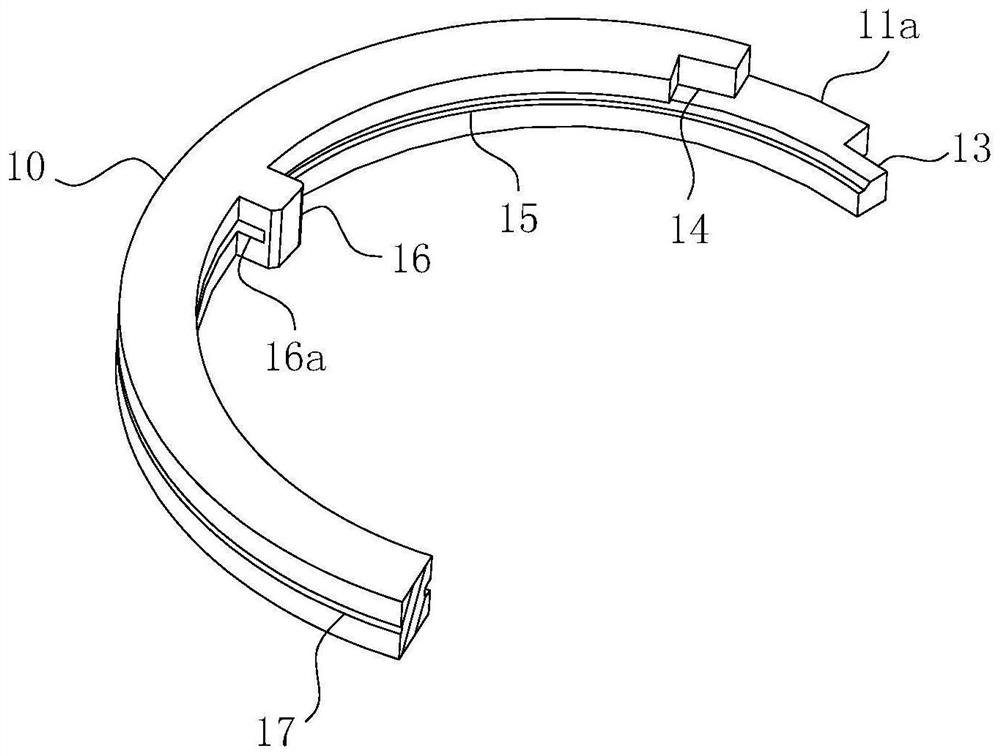

[0030] The specific implementation structure of the present invention can refer to Figure 1-8 As shown, its main structure includes a ring body 10 and an elastic ring 20 . in:

[0031] The shape of the ring body 10 is as follows Figure 1-3 and Image 6 The "C"-shaped open ring shown. In actual production, the openings of the ring body 10 are extended in a snap-like shape such as Figure 1-2 The upper extension block 11a and the lower extension block 12a are shown to form the left step portion 11 and the right step portion 12 accordingly; meanwhile, the sub extension blocks 13 are further extended on the left step portion 11 and the right step portion 12 . In this way, on the one hand, on the traditional split ring structure, the axial flow channel sealing structure is arranged, that is, the left step portion 11 and the right step portion 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com