Full premixed gas wall-hanging stove

A gas-fired wall-hung boiler and fully premixed technology, applied in the field of wall-hung boilers, can solve the problems of wasting water and waiting for a certain time, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application The features in the embodiments and the embodiments can be combined with each other.

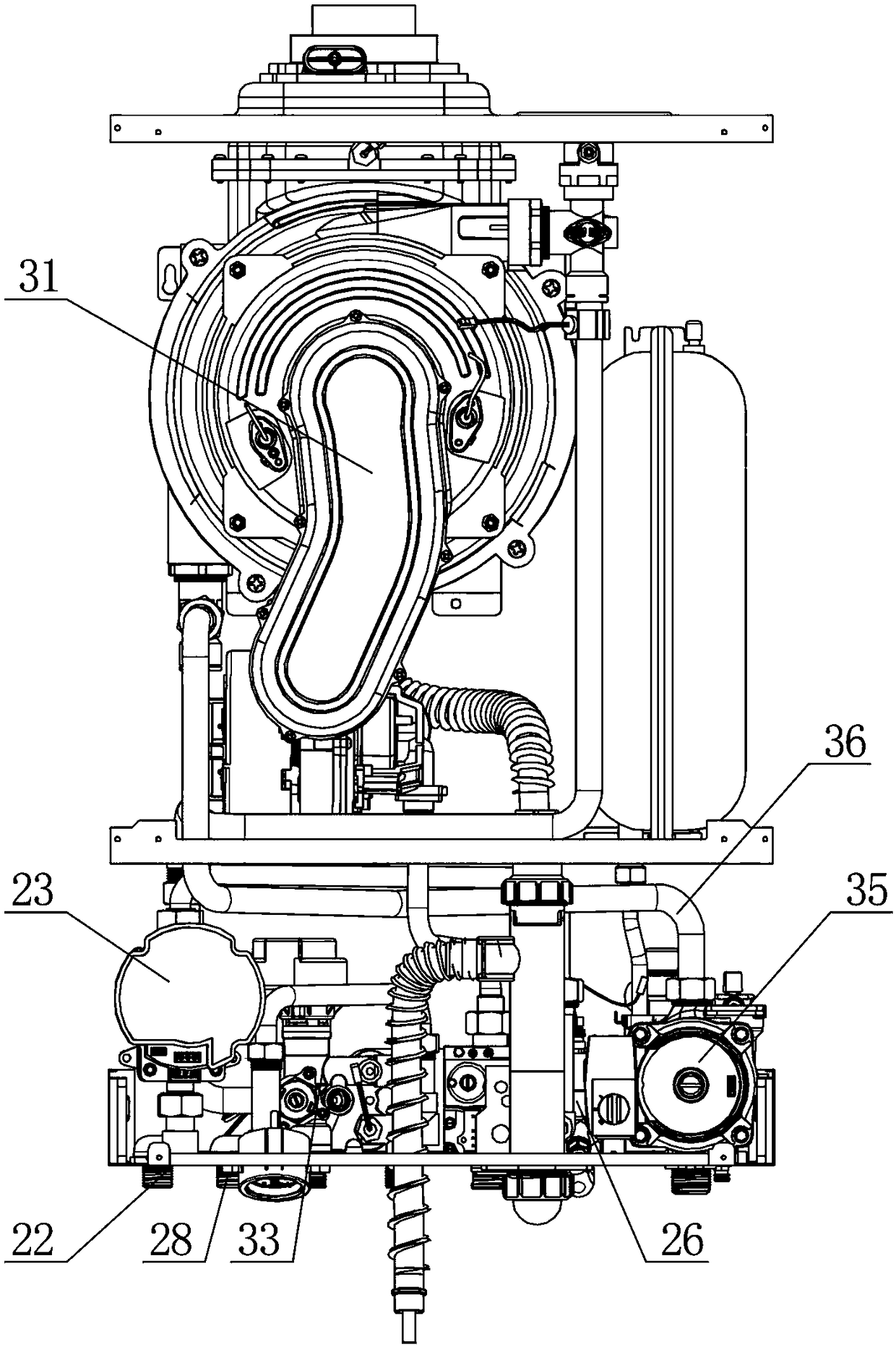

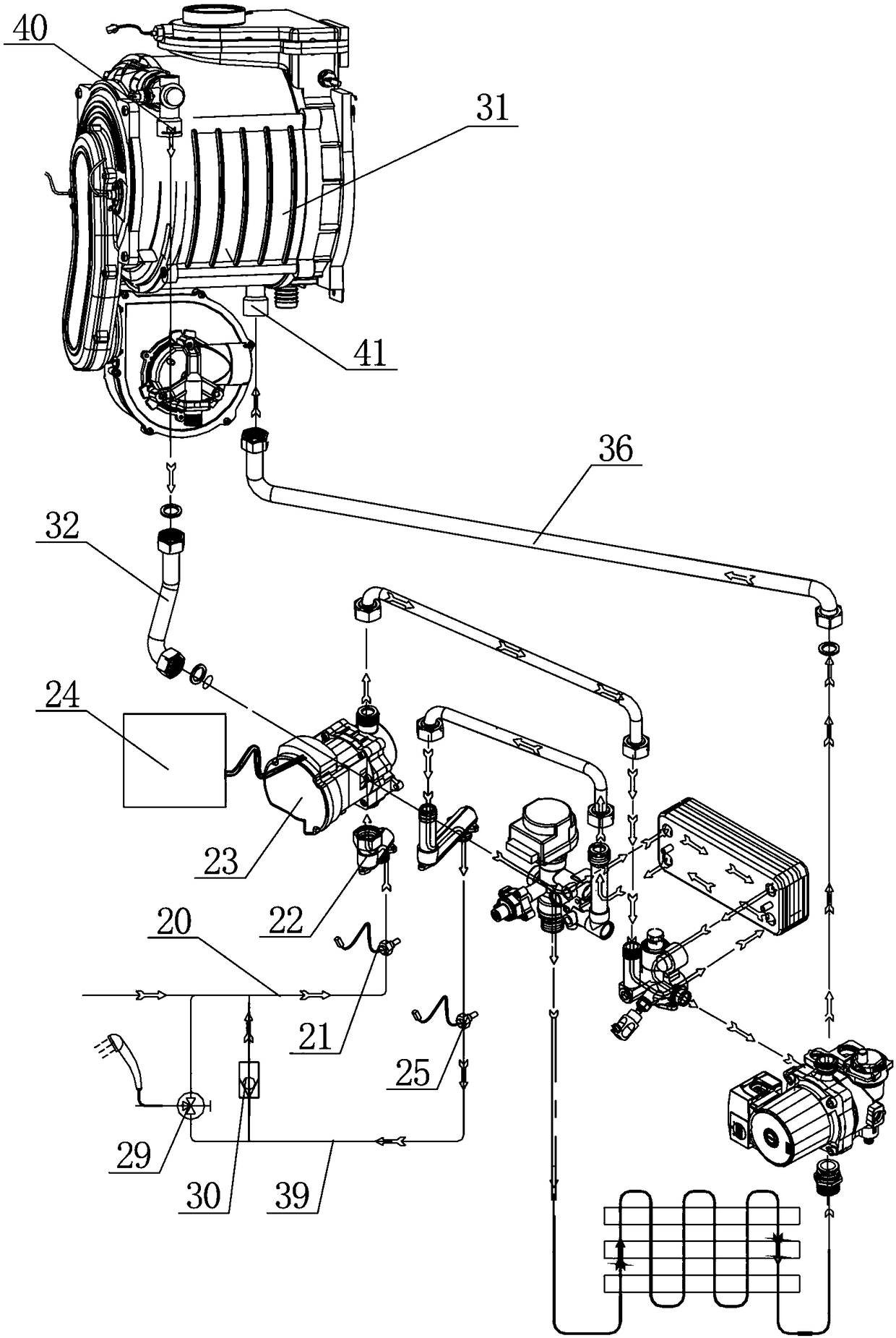

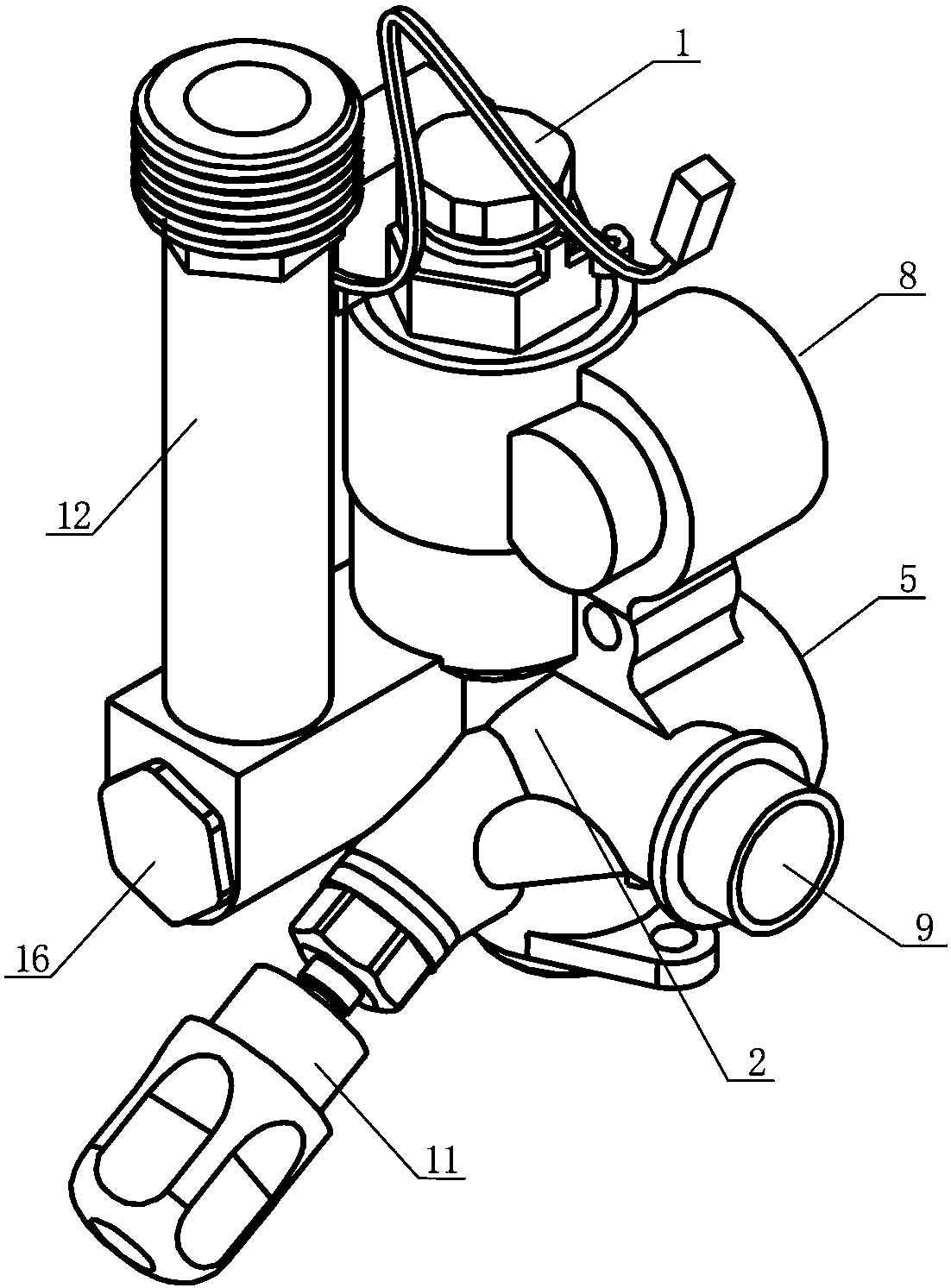

[0040] Such as figure 1 , 2 As shown, the fully premixed gas wall-hung boiler includes a tap water inlet pipe 20, an inlet water temperature sensor 21, a domestic water inlet and cold water joint assembly 22, a booster water pump 23, a controller 24, an outlet water temperature sensor 25, a water flow sensor 26, Plate heat exchanger 27, domestic water outlet and hot water joint assembly 28, domestic water valve 29, one-way valve 30, fully premixed combustion condensing heat exchanger 31, heat medium water discharge pipe 32, electric control three-way valve 33, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com