Automotive anti-overload detecting device

A technology for detection devices and automobiles, which is applied in the direction of measuring devices, weighing indicating devices, instruments, etc., can solve the problems of inability to guarantee the detection accuracy of anti-overload detection devices, increase the production cost of automobile overload detection devices, troublesome installation and disassembly, etc., and achieve The overload detection result is accurate, the use is safe and convenient, and the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

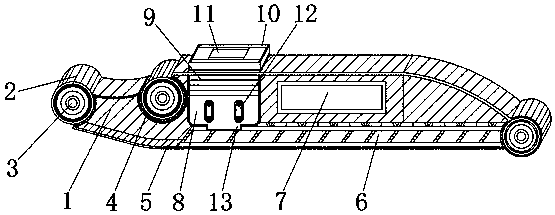

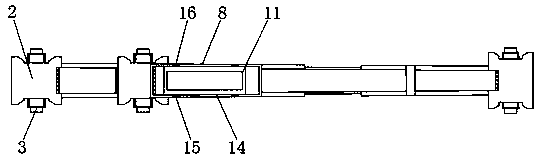

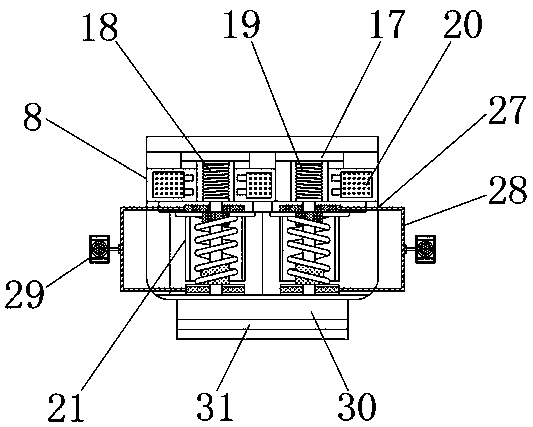

[0024] Example: such as Figure 1-7As shown, the present invention provides a technical solution, an automobile anti-overload detection device, including an automobile longitudinal arm 1, a connecting seat 2, a mounting bush 3, a shock-absorbing pad 4, a wear-resistant side plate 5, and a reinforcement strip 6 , connection keyway 7, overload detector 8, compression folding plate 9, overload detection convex plate 10, connection positioning groove 11, disassembly panel 12, plug-in card block 13, movable groove 14, guide telescopic projection 15, guide Groove rail 16, inner damping assembly 17, damping spring 18, spring guide post 19, overload detection power supply 20, detection assembly 21, inner telescopic guide post 22, overload bearing spring 23, negative magnetic block 24, positive magnetic block 25 , insulation cladding plate 26, threading hole 27, connecting wire 28, overload alarm 29, fixed convex plate 30 and fastening rib 31, and the ends of both sides of the automobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com