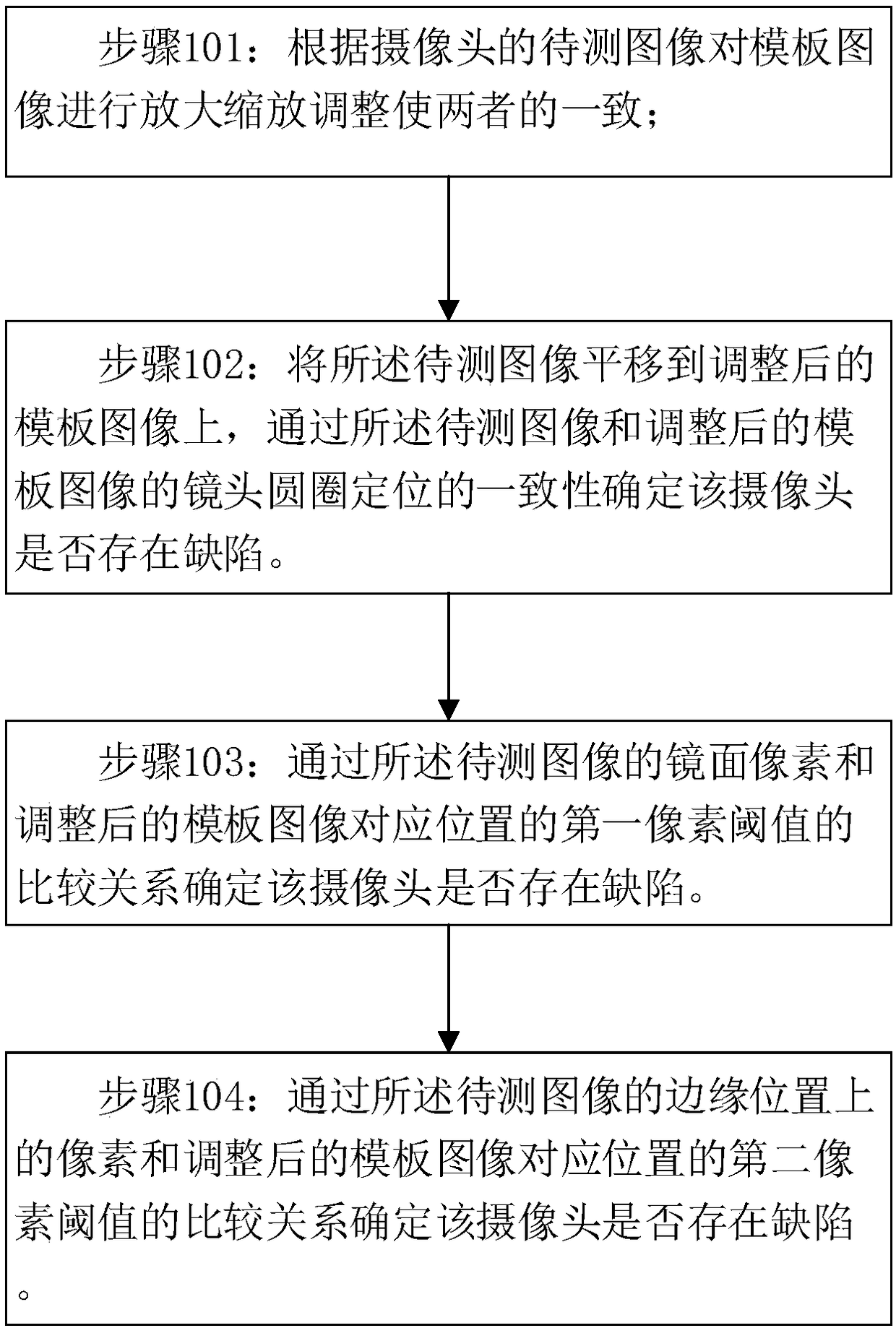

Machine vision based camera defect detection method

A defect detection and machine vision technology, applied in the testing of machines/structural components, optical instrument testing, instruments, etc., can solve problems such as low work efficiency, mirror surface glue overflow, scratches, etc., to improve efficiency and preparation rate, save The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

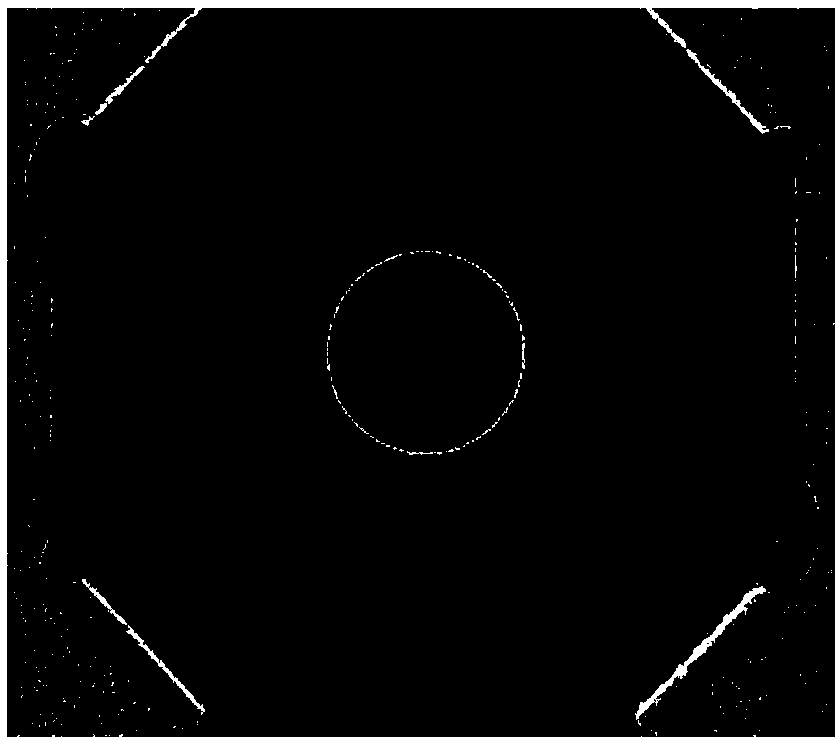

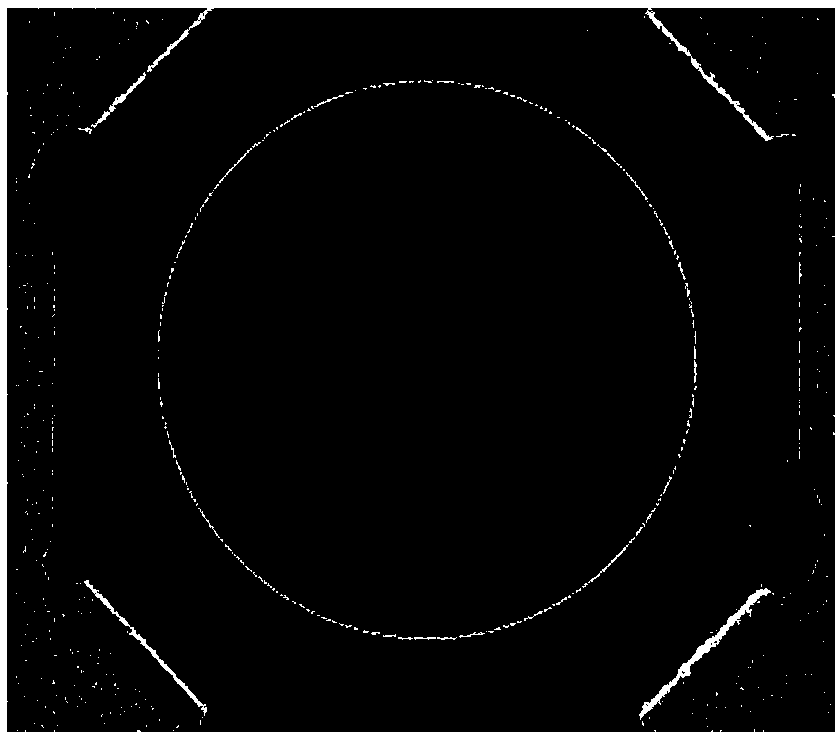

[0026] The camera defect detection technology based on machine vision of the present invention uses template matching and positioning based on gray value sub-pixels. In order not to be affected by factors such as illumination, the gray value of the template must be normalized first, and the image to be tested must be translated to In the template ROI image, calculate the sum of the absolute values of the differences between them. When the sum exceeds a certain range, it is regarded as a defective product, and then these feature points with obvious differences are calculated into a connected domain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com