Metal@graphitized carbon/graphene composite electrocatalyst material and its preparation method

A metal compound and composite electricity technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve environmental pollution, reduce the ratio of M/C heterojunctions, and increase the thickness of carbon shells, etc. problems, to achieve the effect of rich raw material resources, high catalytic activity, and high interface ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

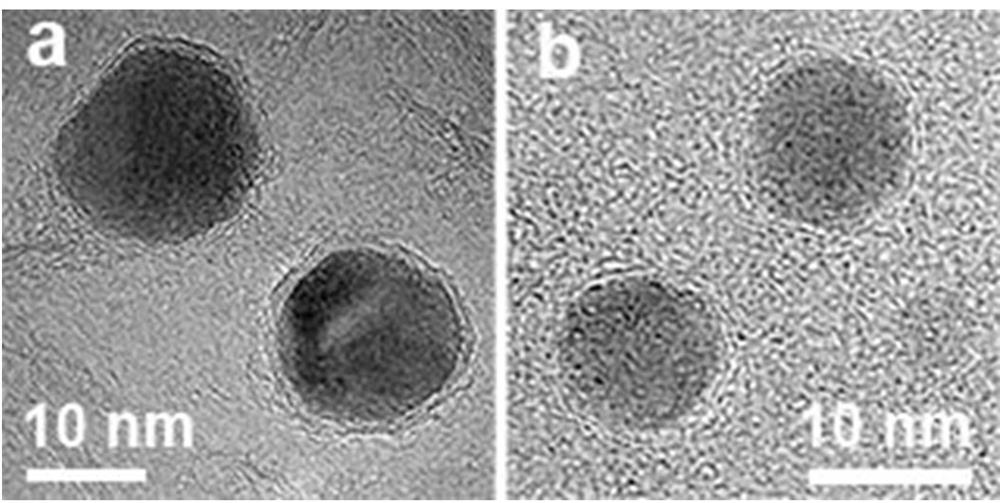

[0027] A 4 mg / mL GO aqueous solution was obtained by the modified hummers method. Add 0.02 mL of 0.5 M potassium ferrocyanide solution to 1 mL of GO aqueous solution under stirring, shake well and add 0.2 mL of 0.5 M nickel chloride solution to it to obtain nickel ferrocyanide / graphene composite, and Wash 3 times with water. The resulting nickel ferrocyanide / graphene composite was dispersed in 1 mL of water, frozen with liquid nitrogen, and then lyophilized in a cold desiccator for 16-24 hours to obtain a nickel ferrocyanide / graphene sponge ( figure 1 ).

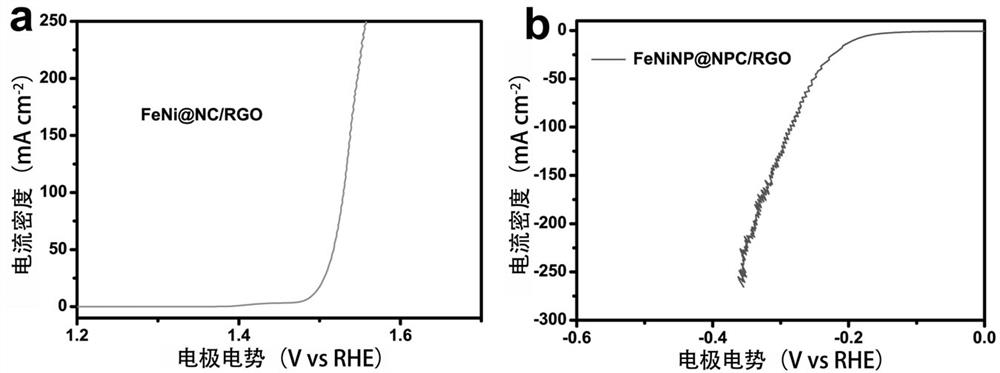

[0028] Transfer the above nickel ferrocyanide / graphene sponge into a glove box containing argon and seal it in a 50 mL quartz vial containing a small amount of carbon cloth. Then put the above-mentioned quartz bottle in a household microwave oven, and use 1000 W of power radiation for 10 s to obtain FeNi@nitrogen-doped grapheneized carbon / graphene composite catalyst ( figure 1 a). As an OER catalyst, it obtains 10mA cm ...

Embodiment 2

[0030] A 4 mg / mL GO aqueous solution was obtained by the modified hummers method. Add 0.02 mL of 0.5 M potassium ferrocyanide solution to 1 mL of GO aqueous solution under stirring, shake well and then add 0.2 mL of 0.5 M nickel chloride solution to obtain nickel ferrocyanide / graphene composite, and Wash 3 times with water. The obtained nickel ferrocyanide / graphene composite was dispersed in 1 mL of 0.6 M urea aqueous solution, frozen with liquid nitrogen, and then lyophilized in a cold desiccator for 16-24 hours to obtain nickel ferrocyanide / graphene containing urea. Graphene Sponge ( figure 1 ).

[0031] Transfer the above-mentioned nickel ferrocyanide / graphene sponge containing urea into a glove box containing argon and seal it in a 50 mL quartz vial containing a small amount of carbon cloth. Then put the above-mentioned quartz bottle in a household microwave oven, and use 1000 W of power to irradiate for 10 s to obtain FeNi nitride@nitrogen-doped graphene-based carbon / g...

Embodiment 3

[0033]A 4 mg / mL GO aqueous solution was obtained by the modified hummers method. Add 0.02 mL of 0.5 M potassium ferrocyanide solution to 1 mL of GO aqueous solution under stirring, shake well and then add 0.2 mL of 0.5 M nickel chloride solution to obtain nickel ferrocyanide / graphene composite, and Wash 3 times with water. The obtained nickel ferrocyanide / graphene composite was dispersed in 1 mL of 0.6 M sodium hypophosphite aqueous solution, frozen with liquid nitrogen, and then lyophilized in a cold desiccator for 16-24 hours to obtain ferrous iron containing sodium hypophosphite Nickel cyanide / graphene sponge ( figure 1 ).

[0034] Transfer the above nickel ferrocyanide / graphene sponge containing sodium hypophosphite into a glove box containing argon and seal it in a 50 mL quartz vial containing a small amount of carbon cloth. Then put the above-mentioned quartz bottle in a household microwave oven, and use 1000 W power to irradiate for 10 s to obtain FeNi phosphide@nitr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap