A Groove Machining Method of Vertical Numerical Control Lathe

A technology of CNC lathes and processing methods, which is applied in the field of vertical CNC lathes, can solve the problems of low efficiency, too many empty tool passes in processing cycle commands, and inconvenient understanding, so as to improve processing efficiency, eliminate empty tool strokes, and save travel. The effect of knife time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with accompanying drawing:

[0022] As shown in the accompanying drawing, this vertical numerical control lathe groove processing method mainly includes the following steps:

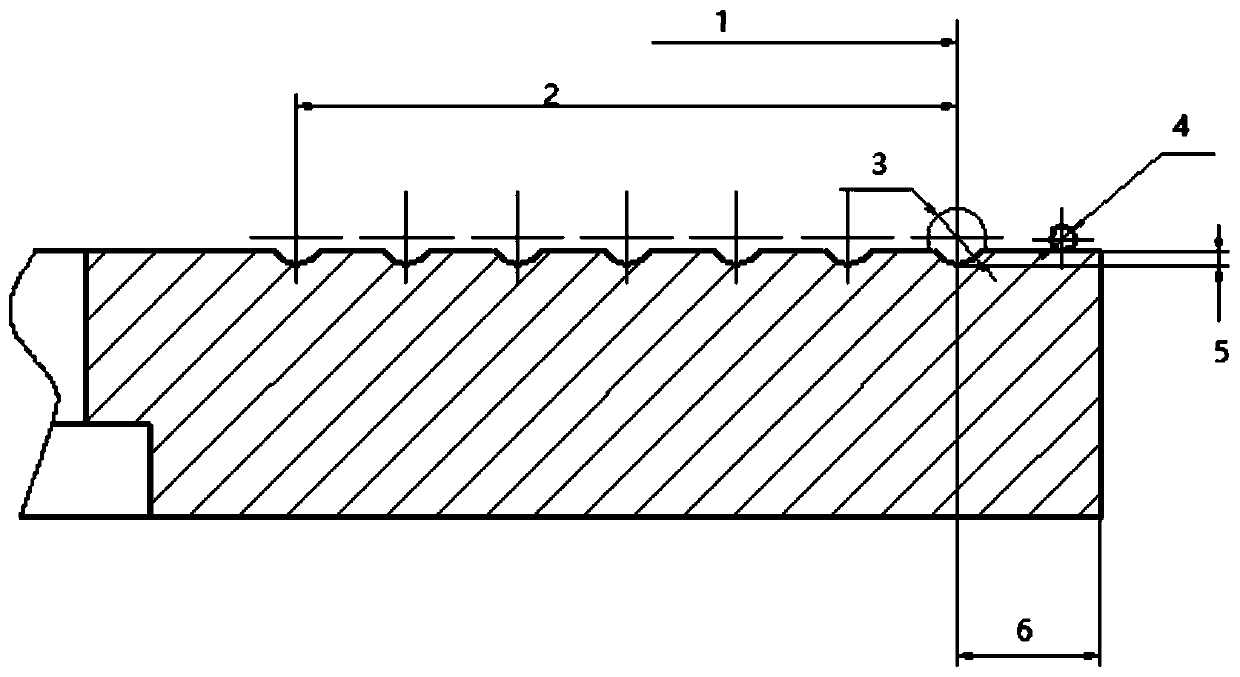

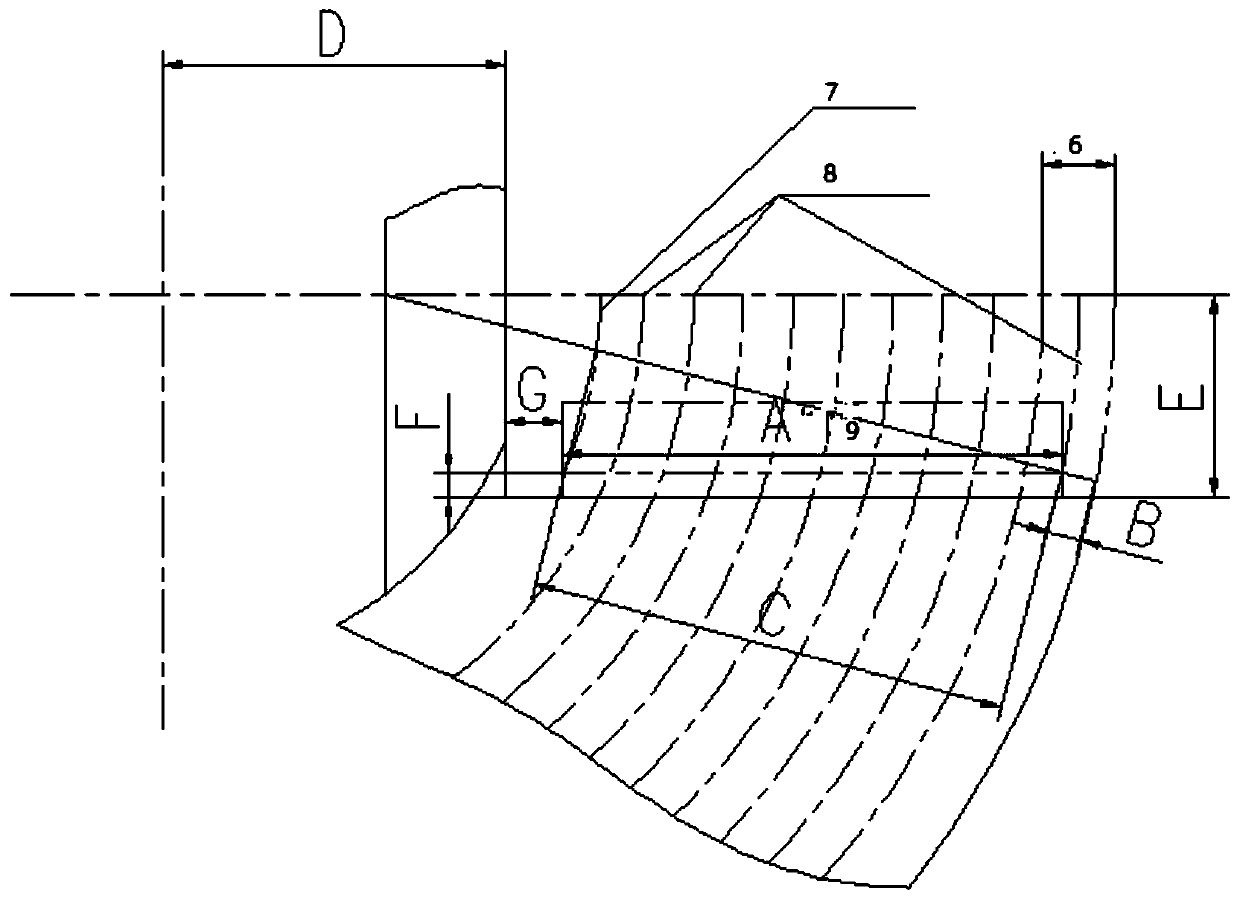

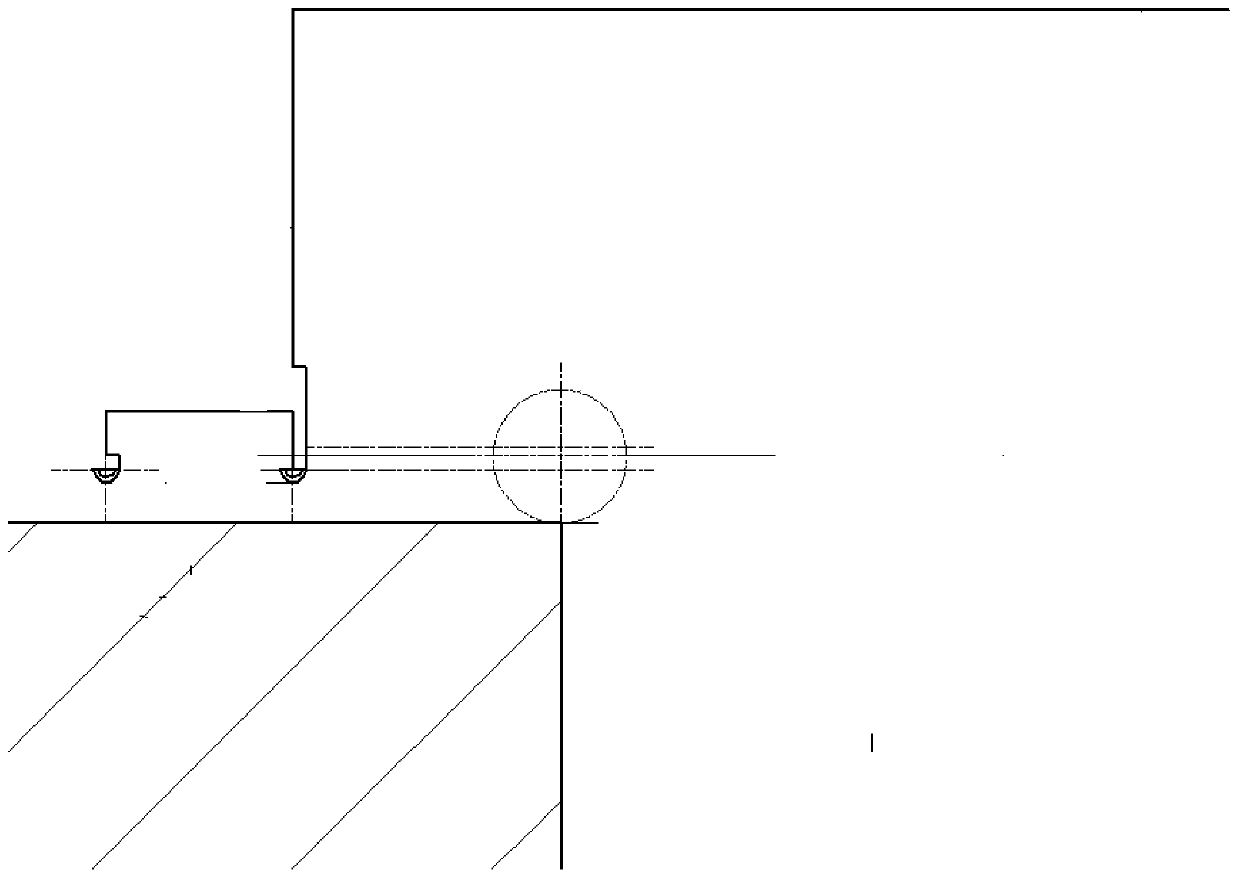

[0023] ① Determine the grinding plate processing parameters: groove outer diameter 1, groove number 2, groove diameter 3, blade diameter 4, groove depth 5, and outer margin 6;

[0024] ②Deduce the programming constant: eccentricity a, that is, the difference between the horizontal line of the tool diameter and the horizontal line of the groove diameter 3, the eccentricity value a=tool radius-(groove radius-groove depth), the eccentricity is classified, the tool diameter line is above, the eccentricity a>0, otherwise, a≤0; when a>0, the size of the rough machining allowance of the arc tool path is subdivided into the selection of the tool path path, and the rough machining allowance of the arc at this time = groove depth -Eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com