Paper pressing device with pre-limiting device for printing machine

A paper pressing technology for printing machines, which is applied in the field of paper pressing devices, can solve problems such as low paper pressing efficiency, low paper pressing efficiency, and unsatisfactory paper flatness, and achieve the effect of improving paper pressing efficiency and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

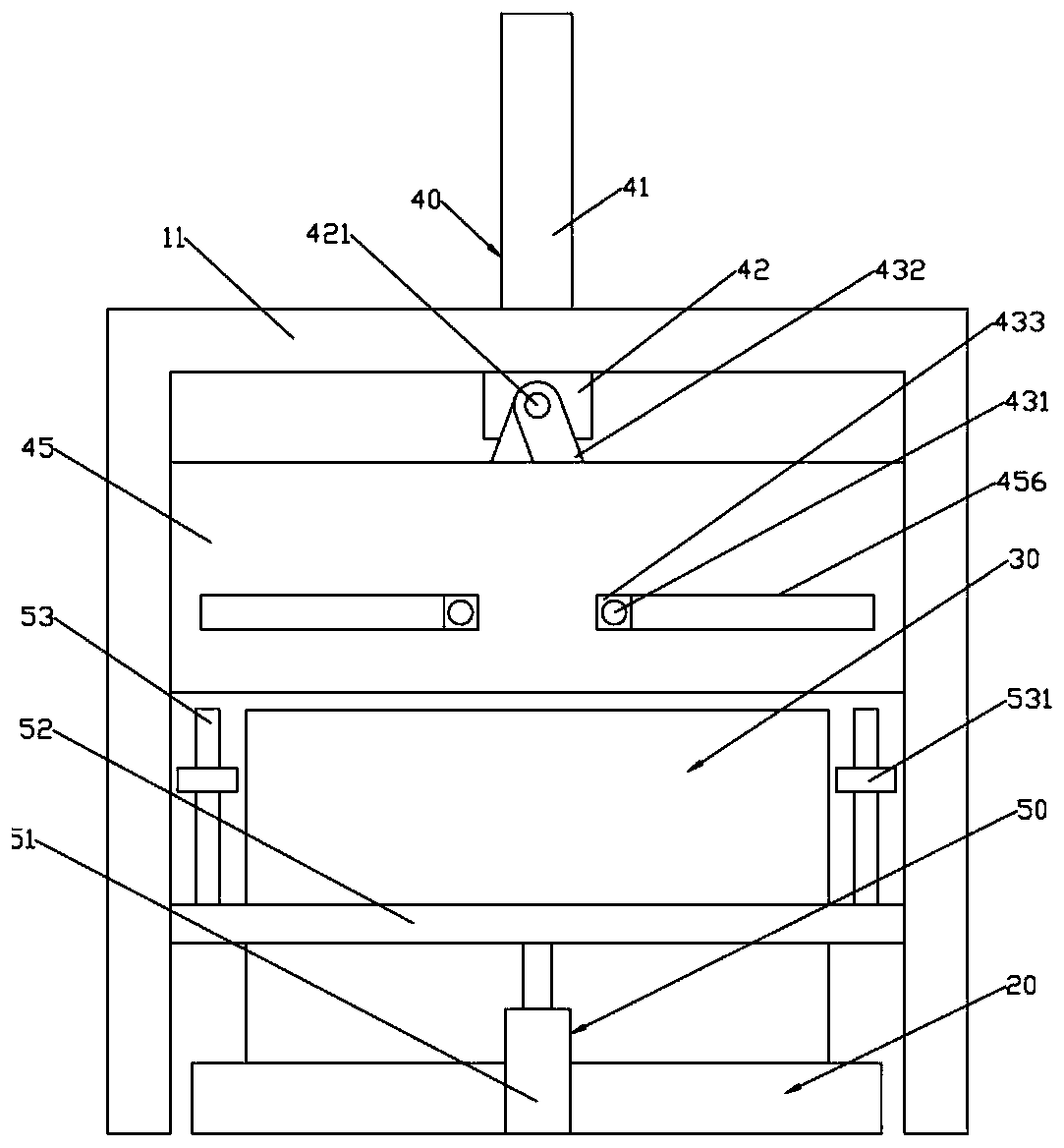

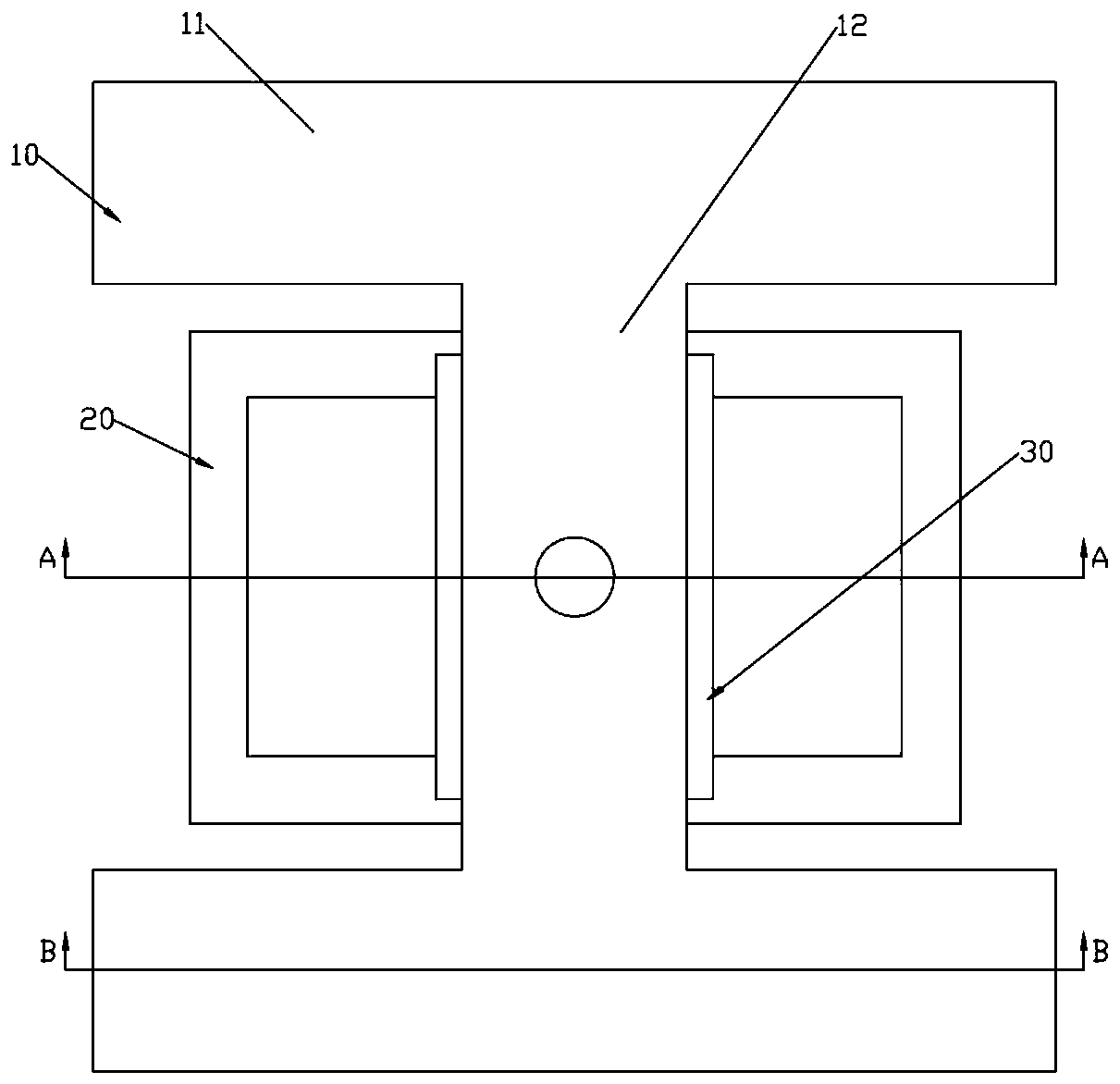

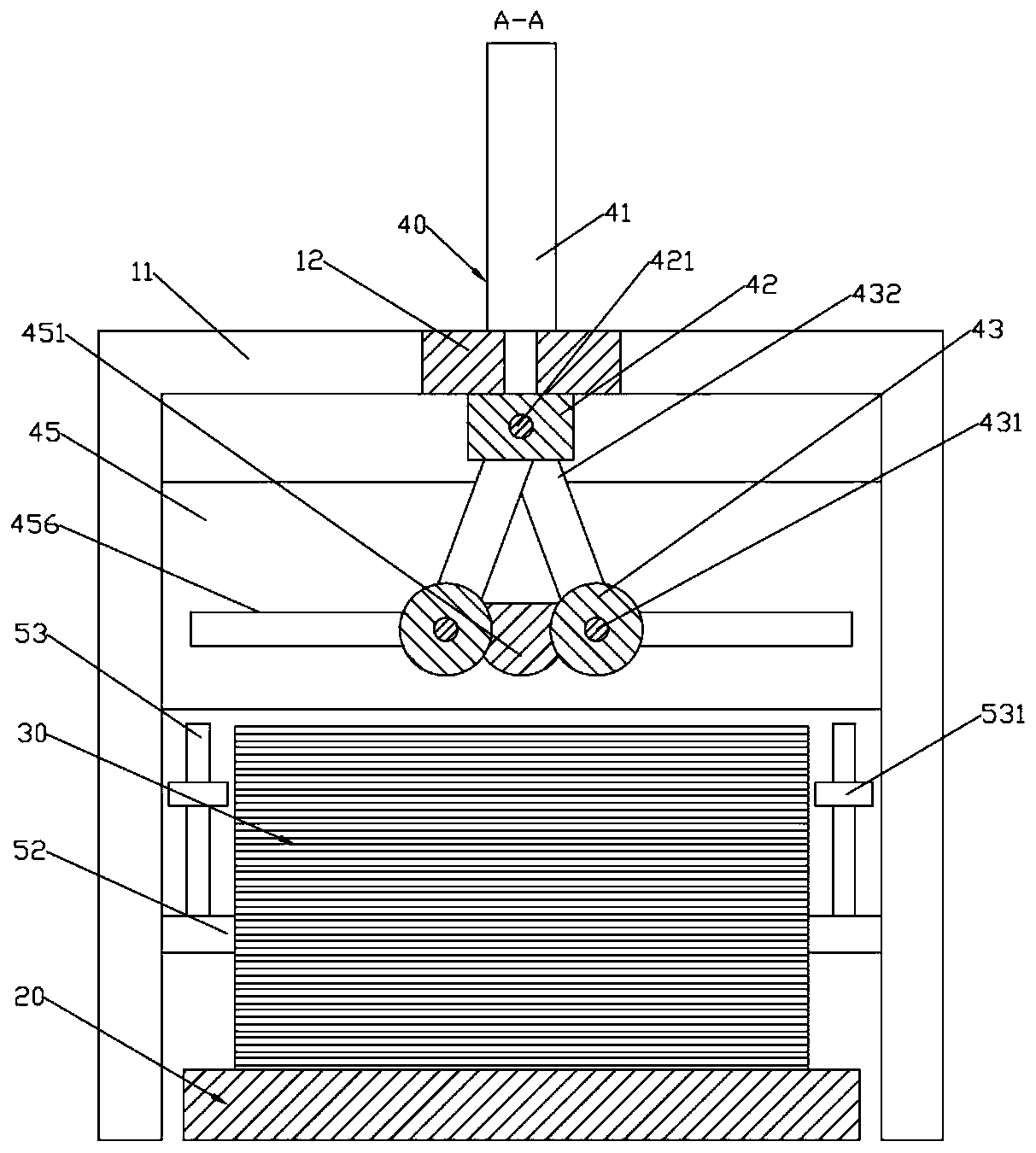

[0015] Such as Figure 1 ~ Figure 4 As shown, a paper pressing device with a pre-limiting device for a printing machine includes a frame 10, a paper placement table 20, a paper stack 30, a paper pressing device 40 and a pre-limiting device 50; the frame 10 includes a pair of The front and rear brackets 11 are arranged symmetrically; the paper placement table 20 is located at the bottom between a pair of front and rear brackets 11; the paper stack 30 is placed on the paper placement table 20; the front and rear brackets 11 are in the shape of "凵" with the opening facing downward; The paper pressing device 40 includes a pair of paper pressing support plates 45 arranged up and down and a pair of pressure rollers 43 arranged symmetrically left and right; a pair of symmetrically arranged rectangular limit drive grooves 450 are formed inside the paper press support plate 45; The lower ends of the front and rear side walls of the slot 450 are respectively formed with rectangular slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com