Circular knife die-cutting machine automatic material receiver

A material catcher and circular knife die technology, which is applied in the mechanical field, can solve the problems that the two materials are not allowed to overlap, frequent material connection, increase the thickness of the material connection position, etc., so as to improve the accuracy and quality of material connection , Reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

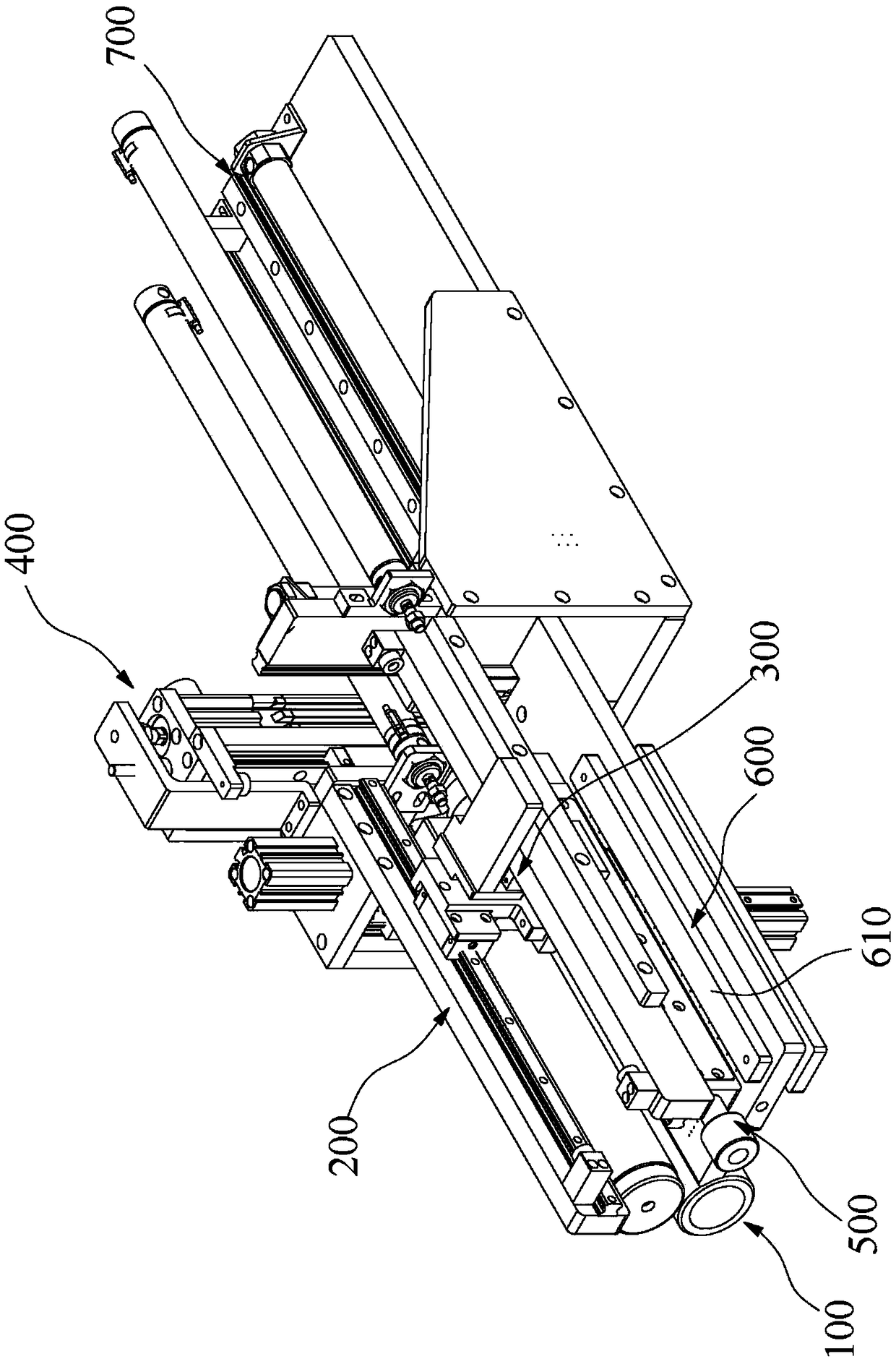

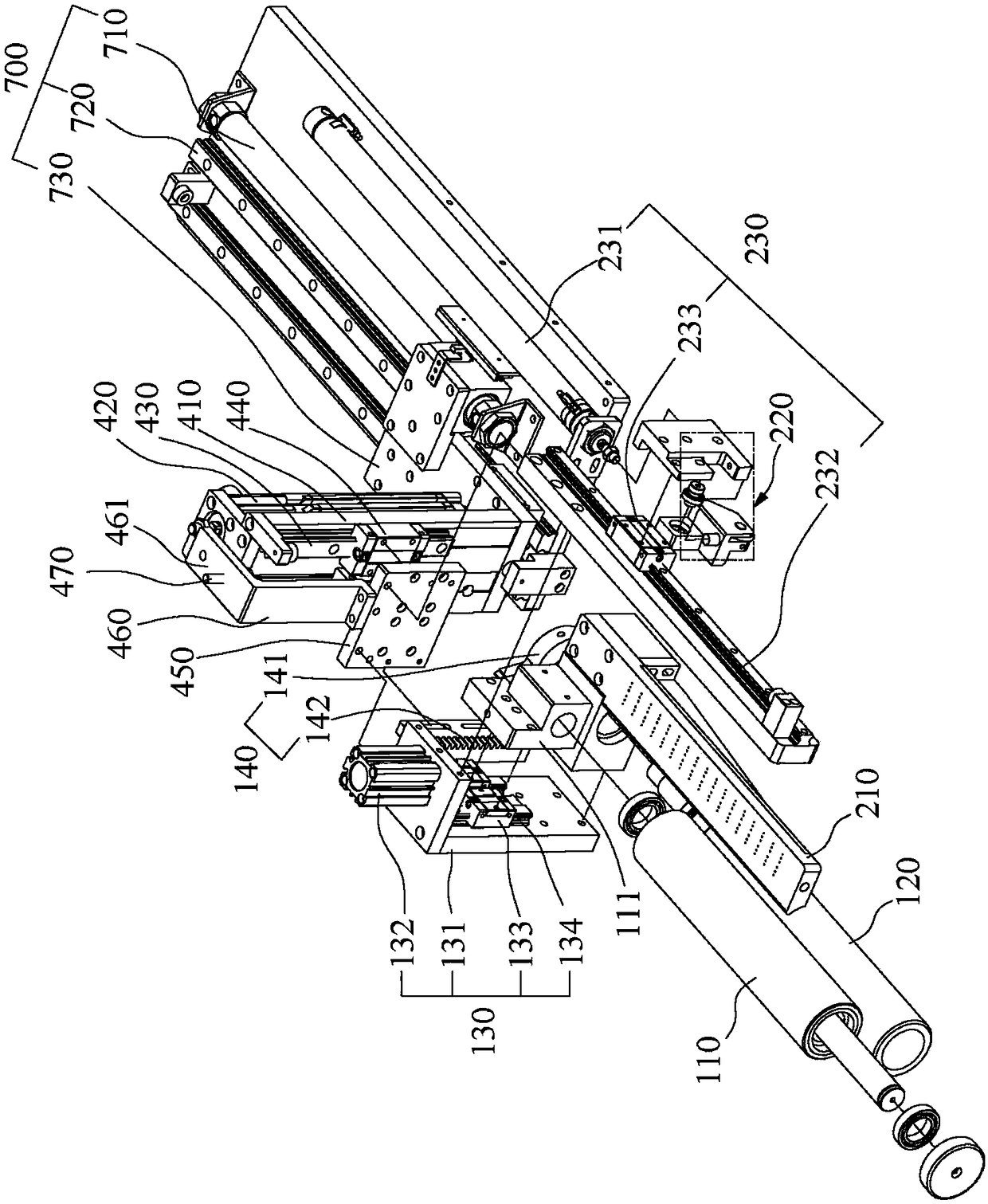

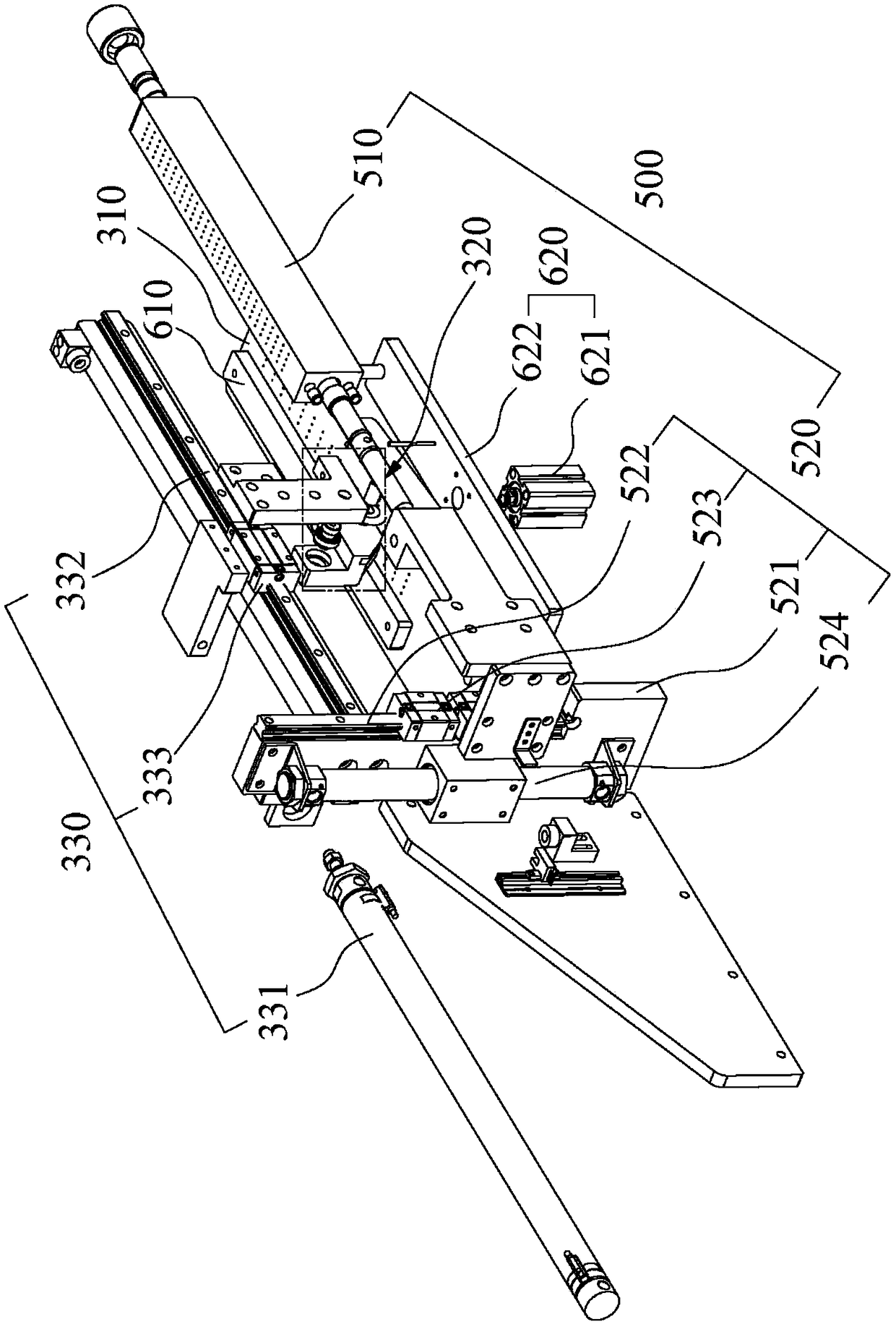

[0030] Attached below Figure 1-7 The present invention is described in further detail.

[0031] According to one aspect of the present invention, an automatic feeder for a circular knife die-cutting machine is provided, and the feeder can connect the spare material tape 800 and the used material tape 900 and stick them together as a whole. like Figure 1-3 As shown, the automatic feeder of the circular knife die-cutting machine in this embodiment includes a feeding mechanism 100, a first cutting mechanism 200, a second cutting mechanism 300, a main lifting mechanism 400, a gluing mechanism 500, and a pressing mechanism 600 and the third driving mechanism 700;

[0032] The feeding mechanism 100 includes an upper roller 110, a lower roller 120, a pressing device 130 for driving the upper roller 110 and the lower roller 120 to compress, and a rotating mechanism 140 for driving one of the upper roller 110 or the lower roller 120 to rotate;

[0033] The first cutting mechanism ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap