Ejection mechanism for engine flip injection mold

A technology of injection mold and ejector mechanism, applied in household appliances, other household appliances, applications, etc., can solve problems such as uneven force, adhesion, product surface scratches, etc., to ensure consistent time, avoid uneven height, The effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

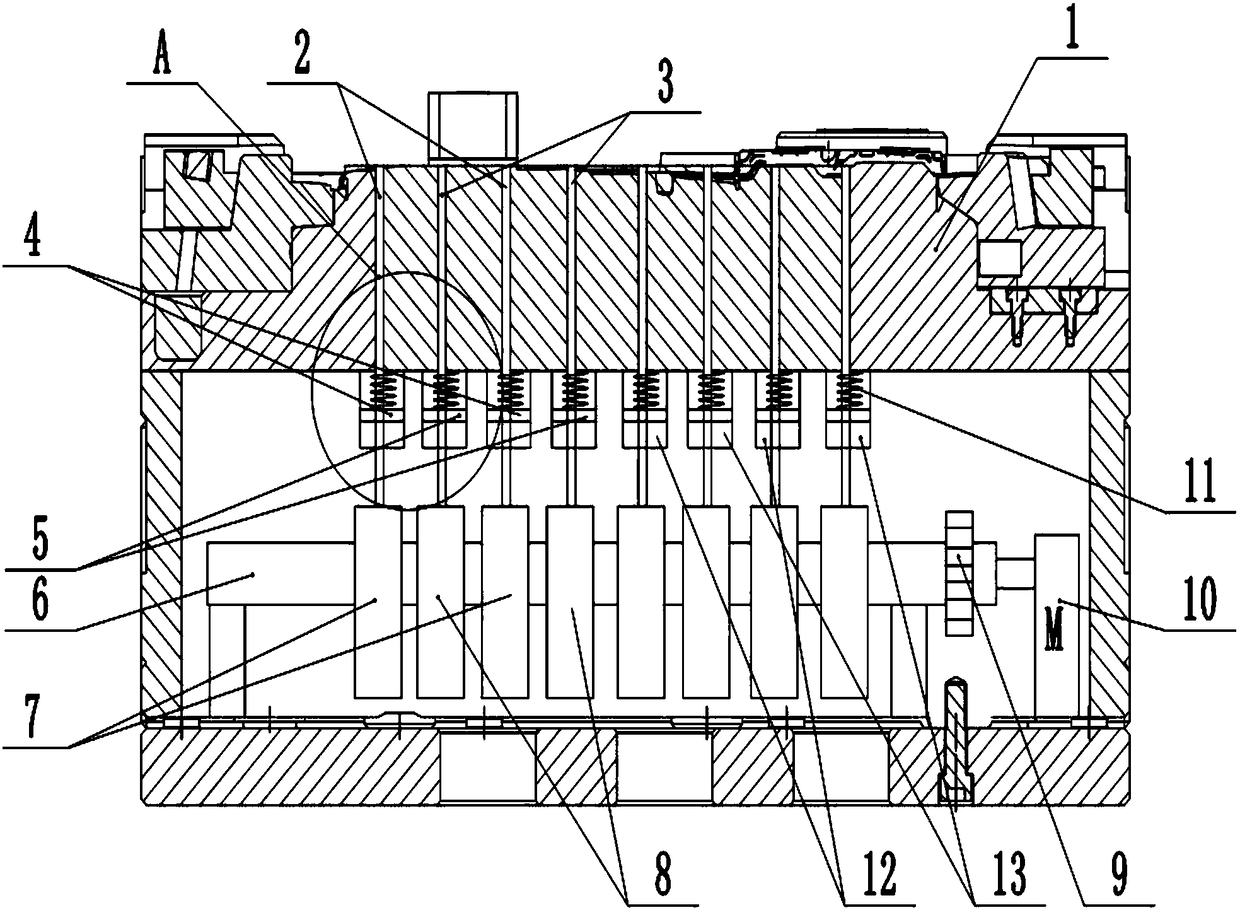

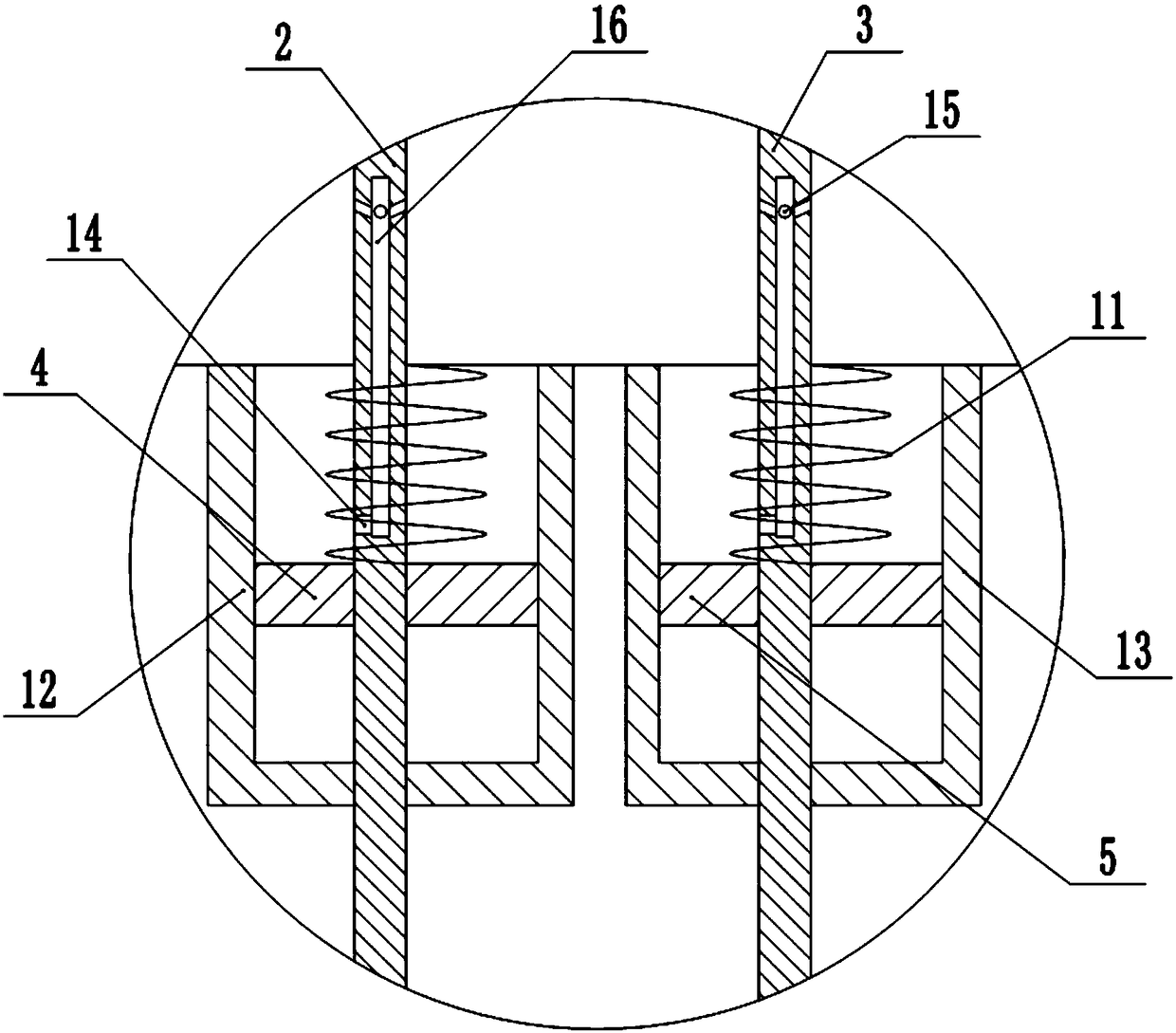

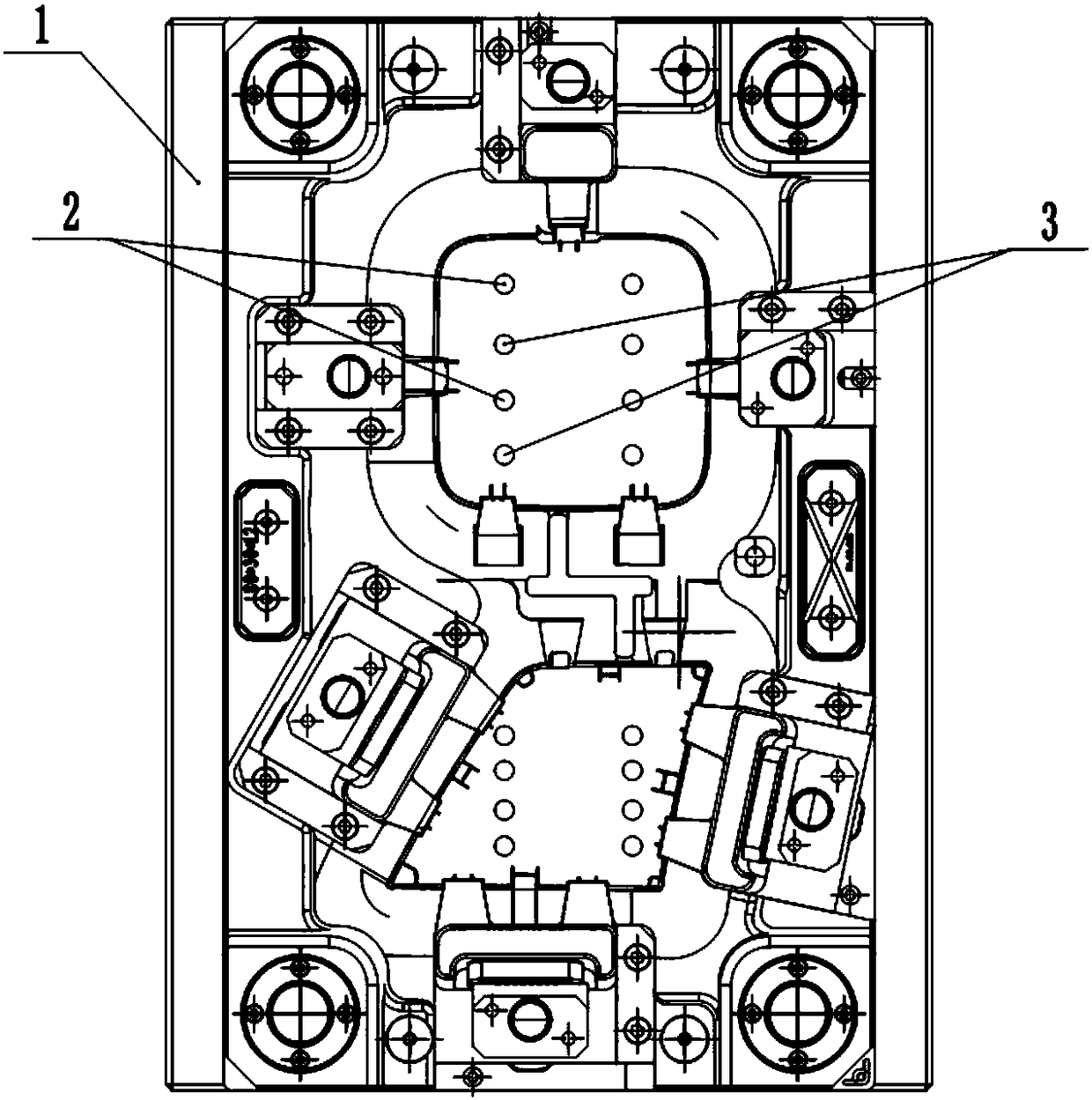

[0026] The reference signs in the drawings of the description include: fixed mold 1, first piston rod 2, second piston rod 3, first piston plate 4, second piston plate 5, rotating shaft 6, first cam 7, second cam 8 , gear 9, motor 10, return spring 11, first cylinder 12, second cylinder 13, air inlet 14, air outlet 15, pipeline 16.

[0027] The embodiment is basically as attached figure 1 , figure 2 and image 3 Shown: The ejection mechanism used for the injection mold of the engine clamshell includes four horizontal rotating shafts 6 arranged between the fixed mold 1 and the base, and the rotating shafts 6 are parallel to each other.

[0028] like Figure 4 As shown: a group of first cams 7 are distributed on the rotating shaft 6; second cams 8 are arranged between adjacent first cams 7, and the line connecting the rotation center of the first cam 7 and the second cam 8 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com