Inflation-free swimming ring and manufacturing process thereof

A non-inflatable, swimming ring technology, applied in the field of swimming rings, can solve the problems of poor safety, poor comfort, lack of support of the ring body jacket, etc., and achieve the effect of avoiding accumulation of odor and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

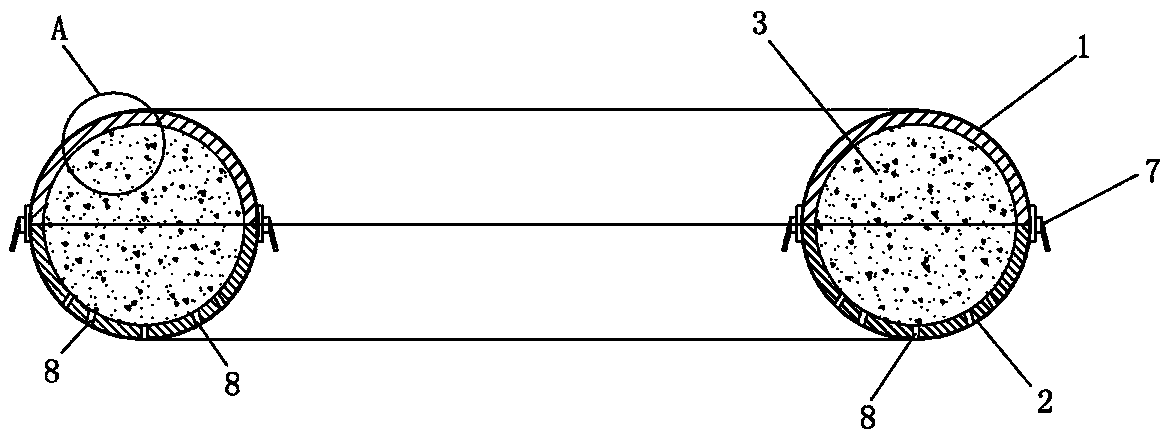

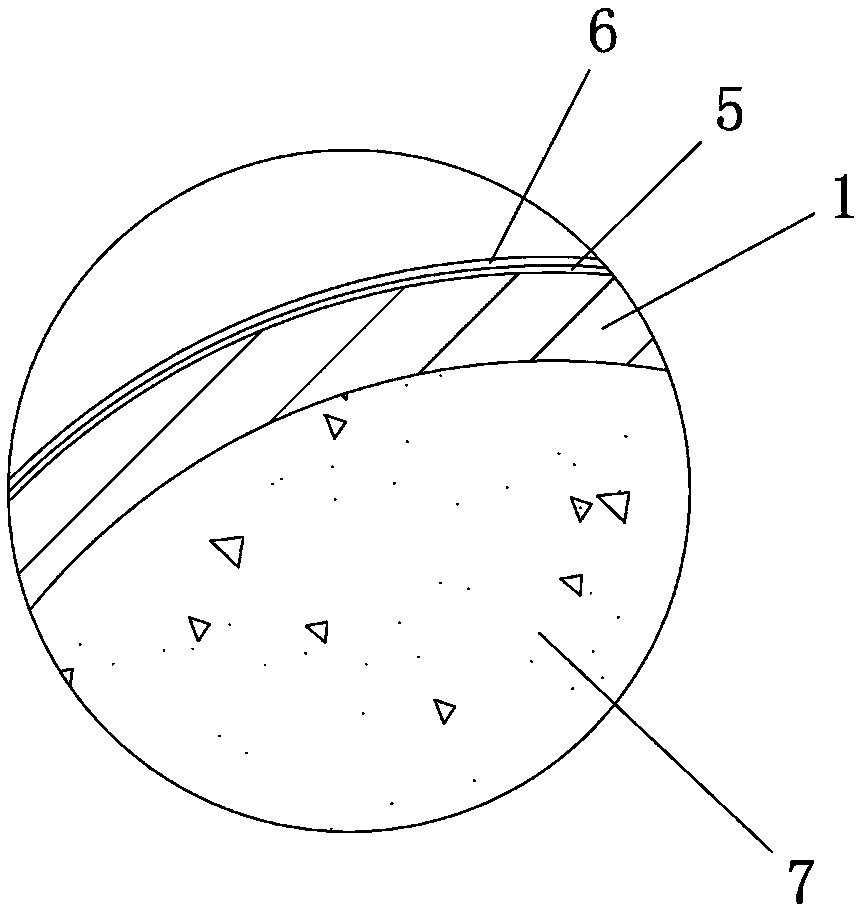

[0015] Such as figure 1 , 2 As shown, a non-inflatable swimming ring includes an upper half ring body 1 and a lower half ring body 2, the upper and lower half ring bodies are made of foaming materials, and the surfaces of the upper and lower half ring bodies are covered with glue Composite layer 5 and surface layer 6, the junction of described upper and lower half ring body is sewn with slide fastener 7 along, upper and lower half ring body is connected by slide fastener 7, upper half ring body 1 and lower half ring body 2 pass through When the zipper is connected, a hollow cavity is formed inside, and a non-absorbent foam material 3 is filled in the hollow cavity, and a plurality of drainage holes 8 are provided on the surface of the lower half circle.

[0016] The production method of the present invention is as follows: first, the plastic foam material is made into a base plate, and the surface of the base plate is covered with an adhesive layer and a surface layer in turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com