A nonwoven oil-absorbing material with kapok sandwich structure

A sandwich structure, oil-absorbing material technology, applied in the directions of grease/oily substance/float removal device, separation method, synthetic resin layered products, etc. degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

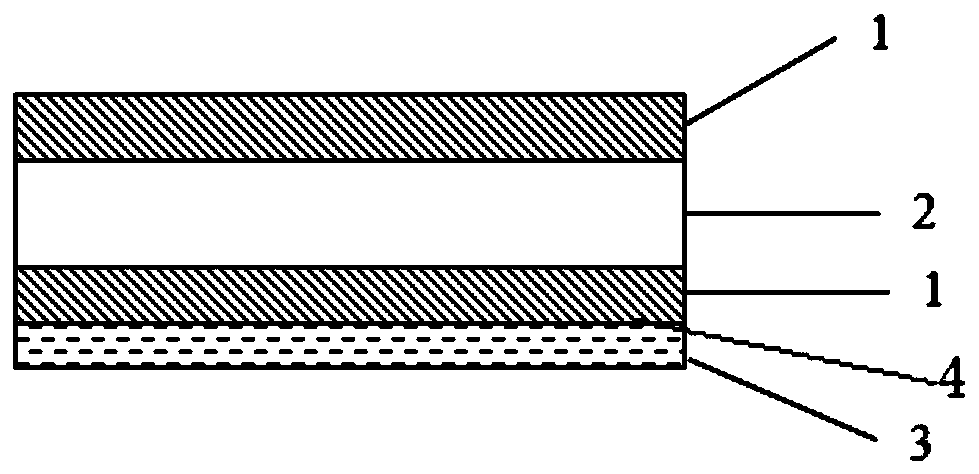

[0018] The oil-absorbing layer 1 and the oil-storage layer 2 are consolidated together through needle punching, and the kapok sandwich layer 4 and the anti-seepage layer 3 are evenly bonded by spraying 5% polyvinyl alcohol solution.

[0019] The grammage of the oil-absorbing layer 1 is 140g / m 2 , the needling density is 40 pricks / cm 2 , the weight of reservoir 2 is 100g / m 2 , the weight of the anti-seepage layer 3 is 40g / m 2 .

[0020] The composite reinforced needling density of oil-absorbing layer 1 and oil storage layer 2 is 50 needles / cm 2 .

[0021] The oil absorption multiple of the kapok sandwich structure nonwoven oil-absorbing material is 19.05g / g, the oil holding rate is 95.50%, and the water absorption rate is 6.81%.

Embodiment 2

[0023] The oil-absorbing layer 1 and the oil-storage layer 2 are combined through needle punching, and the kapok sandwich layer 4 and the anti-seepage layer 3 are evenly bonded by spraying 5% polyvinyl alcohol solution.

[0024] The grammage of the oil-absorbing layer 1 is 140g / m 2 , the needling density is 40 pricks / cm 2 , the weight of reservoir 2 is 100g / m 2 , the weight of the anti-seepage layer 3 is 40g / m 2 .

[0025] The composite reinforced needling density of oil-absorbing layer 1 and oil storage layer 2 is 62.5 needles / cm 2 .

[0026] The oil absorption multiple of the kapok sandwich structure nonwoven oil-absorbing material is 18.23g / g, the oil holding rate is 95.93%, and the water absorption rate is 8.24%.

Embodiment 3

[0028] The oil-absorbing layer 1 and the oil-storage layer 2 are combined through needle punching, and the kapok sandwich layer 4 and the anti-seepage layer 3 are evenly bonded by spraying 5% polyvinyl alcohol solution.

[0029] The grammage of the oil-absorbing layer 1 is 140g / m 2 , the needling density is 40 pricks / cm 2 , the weight of reservoir 2 is 100g / m 2 , the weight of the anti-seepage layer 3 is 40g / m 2 .

[0030] The composite reinforced needling density of oil-absorbing layer 1 and oil storage layer 2 is 75 needles / cm 2 .

[0031] The oil absorption multiple of the kapok sandwich structure nonwoven oil-absorbing material is 17.28g / g, the oil holding rate is 96.81%, and the water absorption rate is 9.83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap