Fabrication method for novel craft sculpture

A technology of sculpture and new craftsmanship, applied in decorative arts, decorative structures, etc., can solve the problems of long construction period, difficult curing, and lengthening molding time, and achieve the effect of overcoming long development construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

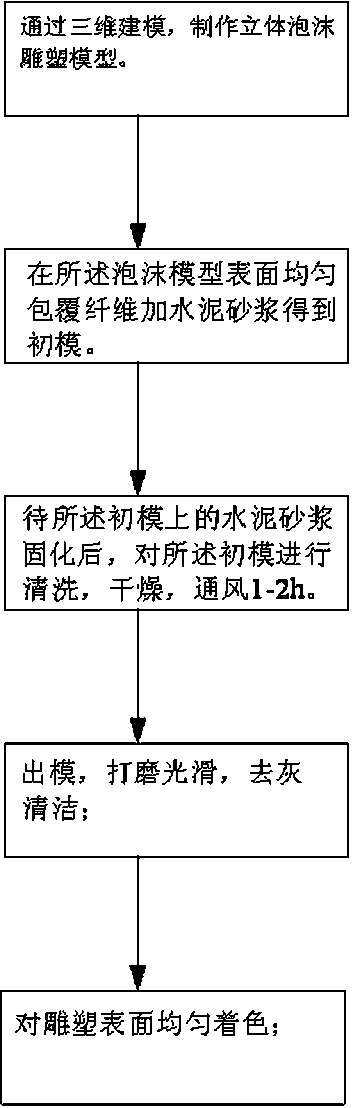

[0018] Such as figure 1 Shown, the present invention comprises the following steps:

[0019] The foamed plastic (Styrofoam) sculpture is molded, and 0.8-1.2 cm of fiber and cement mortar are evenly coated on the surface of the above-mentioned foamed plastic (Styrofoam), and molded when the cement is not dry. After the cement mortar is solidified, it is cleaned, adjusted, polished, colored, and finished.

[0020] (1) Through three-dimensional modeling, make a three-dimensional foam plastic (Styrofoam) model;

[0021] (2) On the surface of the above-mentioned foamed plastic (Styrofoam) model, evenly coat fiber and add cement mortar to obtain the initial mold;

[0022] (3) After the cement mortar on the primary mold is solidified, the primary mold is cleaned, dried, and ventilated for 1-2 hours;

[0023] (4) Release the mold, polish it smoothly, remove dust and clean;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com