Rail guided vehicle with fork-position transverse transmission function

A horizontal and trolley technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of cargo handling, can not meet the needs of rail car transmission, etc., to achieve reliable mobility, simple structure, easy disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

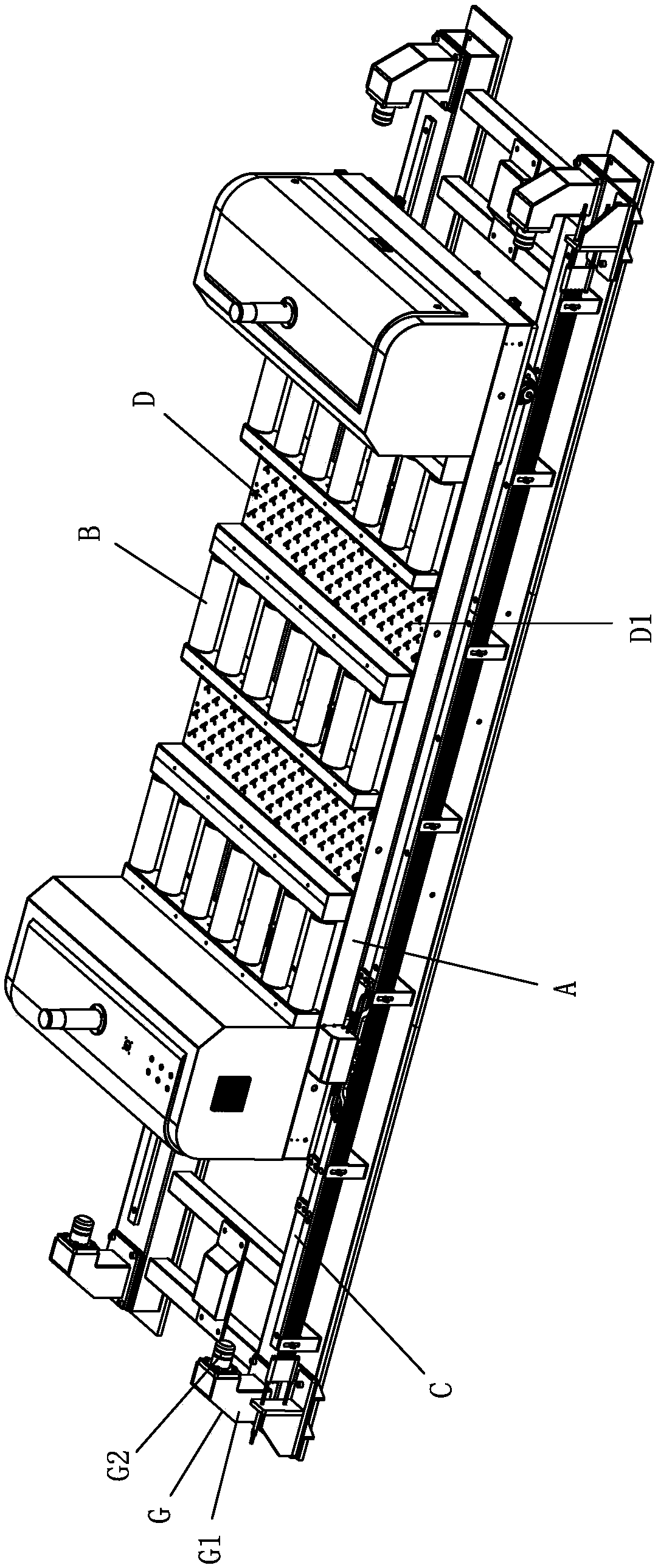

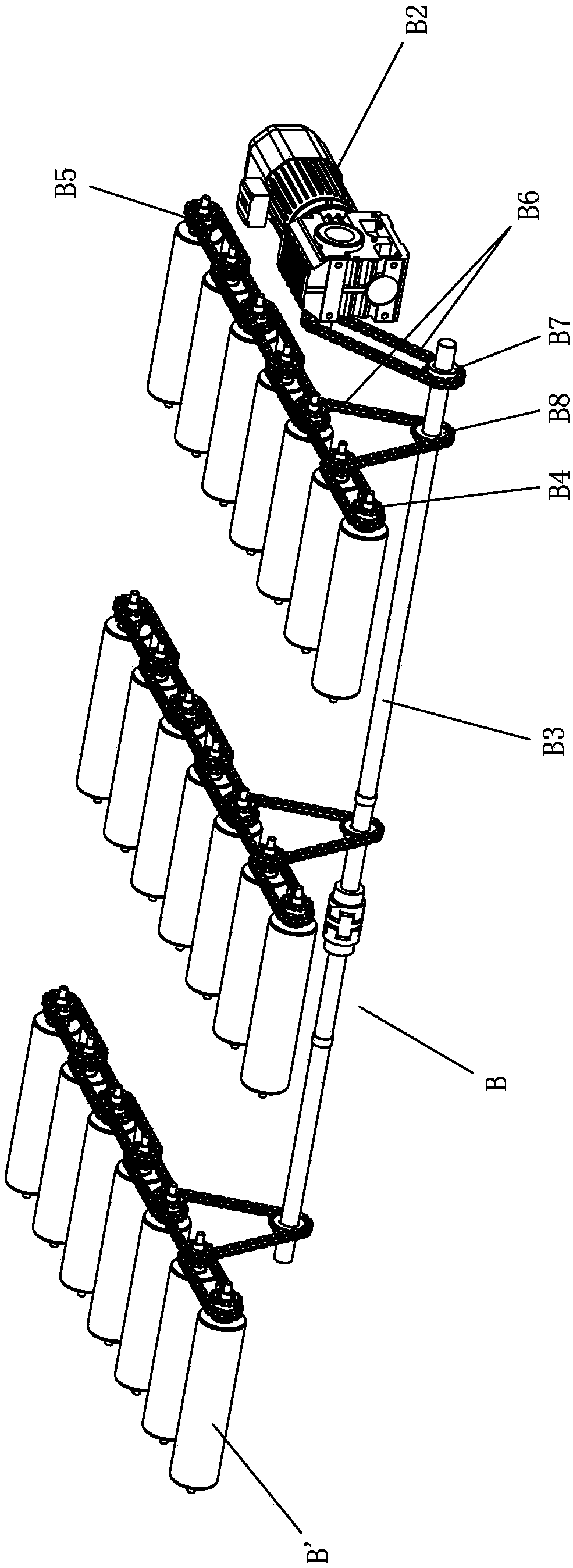

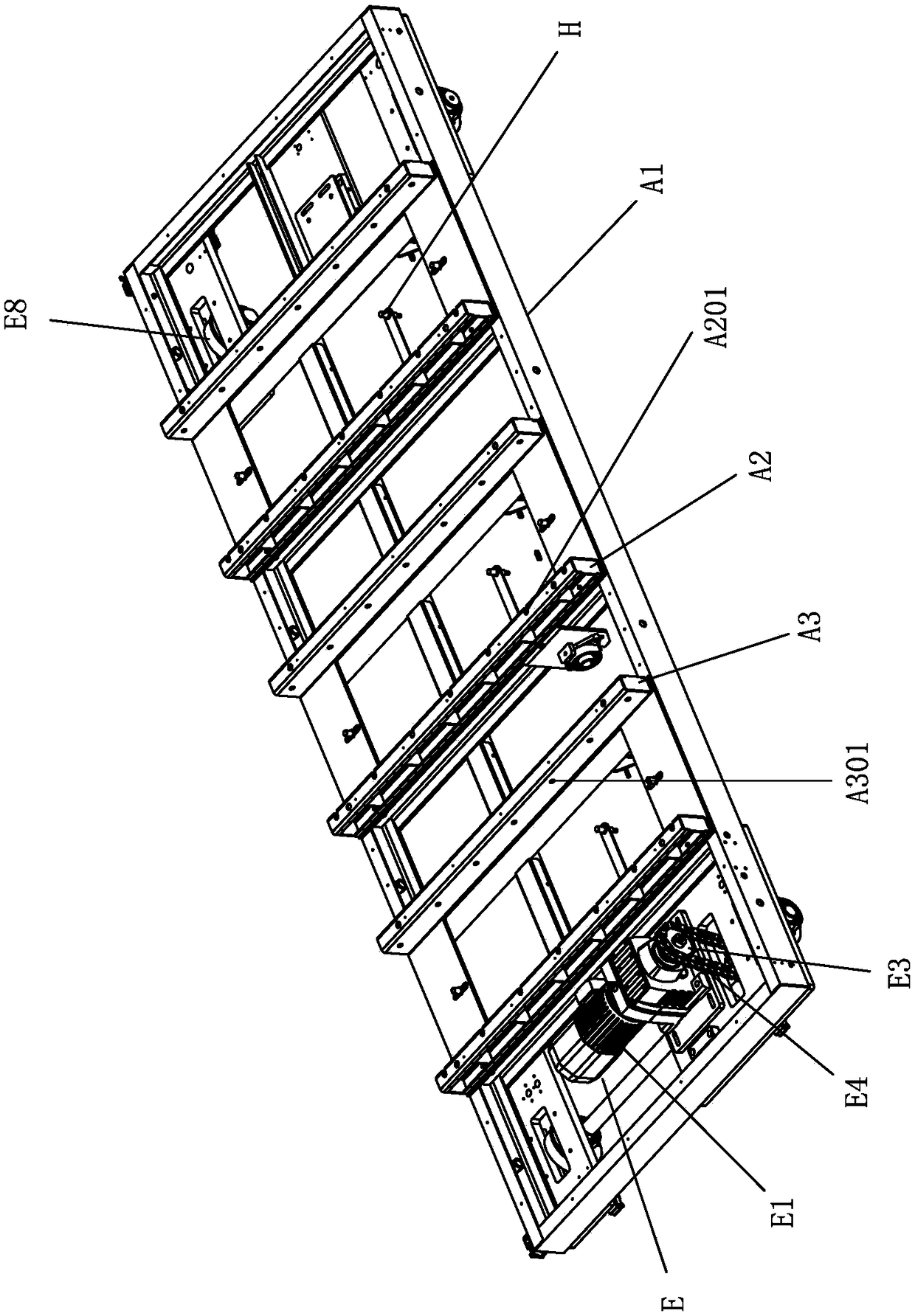

[0023] see Figure 1-Figure 4 , the trolley with the function of fork lateral transmission includes a fork lateral transmission mechanism B and a trolley drive mechanism E respectively arranged on the car body A. The fork lateral transmission mechanism B includes two or more sets of lateral transmission units B' composed of several lateral transmission rollers B1, and a lateral transmission drive assembly for driving each lateral transmission roller B1 to rotate. Each lateral transmission roller B1 is positioned and rotated on the vehicle body On A, the horizontal transmission units B' are arranged in intervals, and there is a fork avoidance gap D between two adjacent horizontal transmission units B'. Handling; the horizontal transmission drive assembly includes a transmission drive motor B2, which drives each horizontal transmission roller B1 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com