Intelligent type stacking mechanical hand operation control system and control method thereof

An operation control and manipulator technology, applied in conveyor control devices, conveyors, stacking of objects, etc., can solve problems such as sheet scratches, affecting sales, and deformation of gussets or wall panels, achieving short operation cycles, mobile And the effect of stable lifting and accurate stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention discloses an intelligent stacking manipulator operation control system and an intelligent stacking manipulator operation control method. The specific implementation modes of the present invention will be further described below in combination with preferred embodiments.

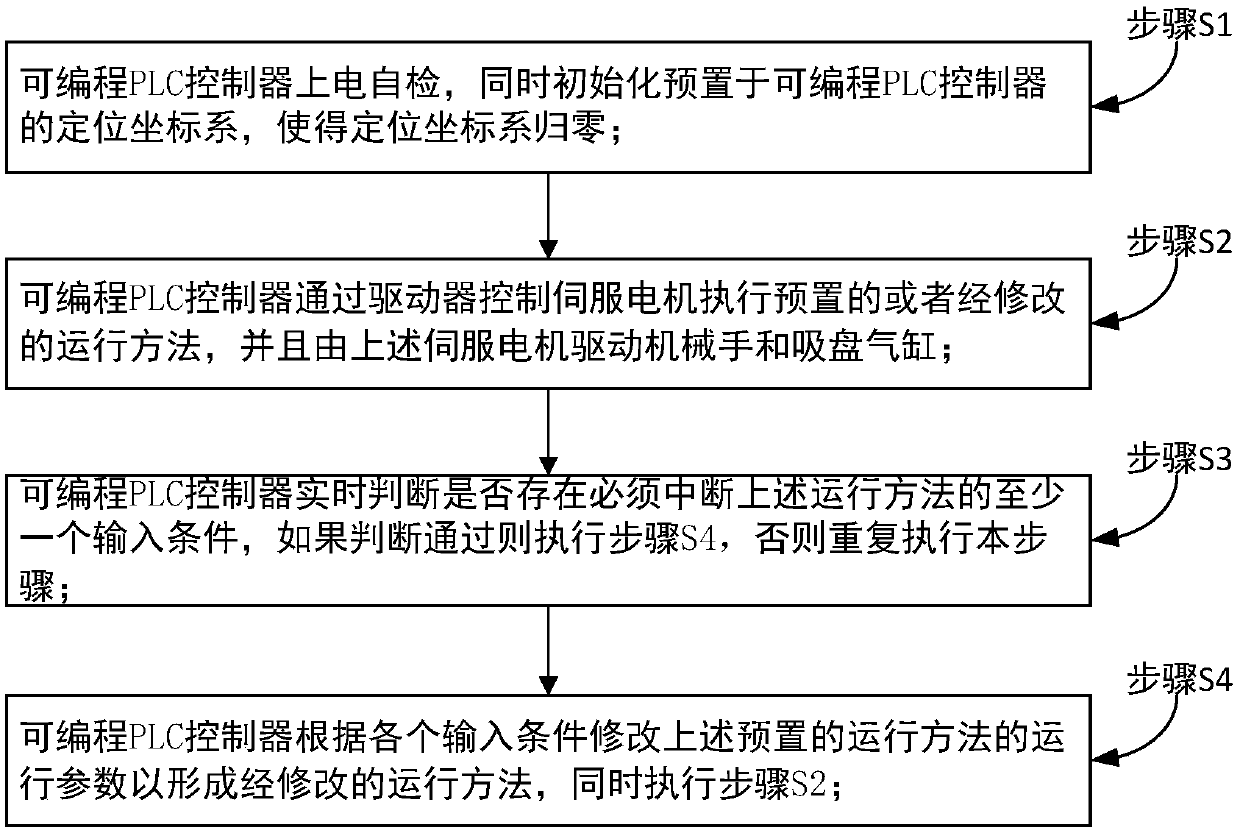

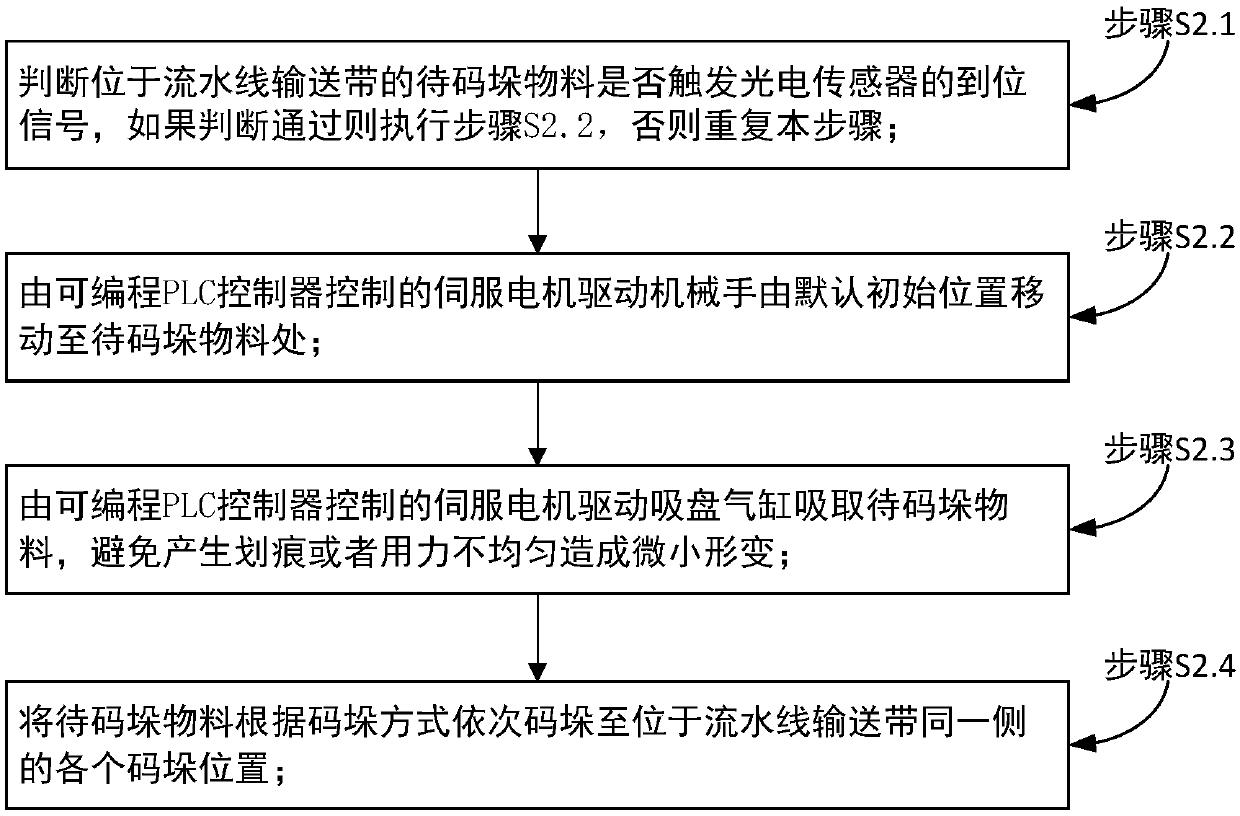

[0037] see attached figure 1 and figure 2 , figure 1 The main steps of the intelligent stacking manipulator operation control system and its control method are shown, figure 2 It shows the main steps of step S2 of the intelligent stacking manipulator operation control system and its control method.

[0038] Preferably, the operation control method of the intelligent stacking manipulator includes the following steps:

[0039] Step S1: The programmable PLC controller is powered on for self-test, and at the same time initializes the positioning coordinate system preset in the programmable PLC controller, so that the positioning coordinate system is reset to zero (that is, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com